-

R&D

-

Production

-

Sales

company Profile

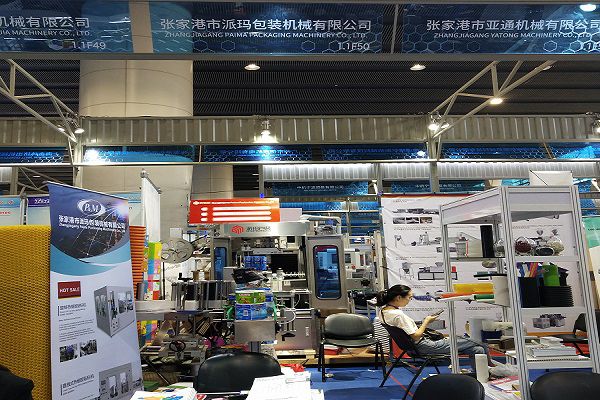

Zhangjiagang Paima Packaging Machinery Co., Ltd. is located in Zhangjiagang , a city with developed economy in the Yangtze River Delta. It was established in 2009 and is closely connected with cities such as Shanghai, Suzhou and Wuxi. The transportation is very convenient for customers in the north and south of the country.

View More