want to know more about machines ? contact us now

The process requirements for making juice and tea beverages are strict. From the comprehensive comparison of PET bottle filling process technology, production line operability, beverage quality, etc., it is more economical and reliable to use the hot filling process.

Brief introduction of juice filling machine

The process requirements for making juice and tea beverages are strict. From the comprehensive comparison of PET bottle filling process technology, production line operability, beverage quality, etc., it is more economical and reliable to use the hot filling process. The hot filling requires that fruit juice and tea beverages be sterilized by UHT instantaneous ultra-high temperature and maintained at a fixed value between 85°C and 95°C, and the filling ends in a short time, which is a high-temperature filling. Juice and tea beverages, especially for the production of original beverages, require the material to be filled, that is, until the bottle is full so that there is very little residual air in the bottle, which can ensure that the beverage itself is not easy to be oxidized so that the beverage can be maintained for a long time of Its quality. Since hot filling must have the functions of high-temperature filling and full mouth-filling, it is required to be equipped with an automatic circulation system, which is convenient for low-temperature material circulation heating and CIP circulation cleaning equipment.

|  |

1. Dilution: The thawed concentrated juice is diluted with purified water according to the formula requirements.

2. Filtration: Remove suspended solids and impurities in the juice, so that the diluted juice can be clear and transparent.

3. Homogenization: Homogenize the diluted juice to make the juice uniform and stable. Homogeneous pressure requirement: 20-25MPa.

4. Sugar dissolving and filtering: carried out in the sugar dissolving tank. Start the blender, add the right amount of water, and add the white sugar according to the formula. There are two ways to dissolve sugar, hot melt and cold melt, one of which can be selected according to the needs of the production process. Diatomaceous earth filtration is generally used for the filtration of sugar liquor. The dissolution and filtration of other auxiliary materials are basically the same as that of white sugar.

5. Blending: Pump the diluted juice, the dissolved and filtered sugar solution, and then dissolved and filtered auxiliary materials to the blending tank to mix them evenly and make the volume constant. Add flavors and (or) pigments according to the formula and mix well.

6. Filtration: Filter the mixed material and liquid through the filter barrel connected to the pipeline again to completely remove the possible suspension. To ensure the transparency, uniformity, and no precipitation of the product.

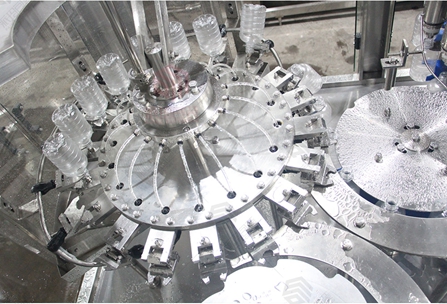

7. Washing: The bottle passes through the bottle washing machine to fully clean the dust and dirt that may exist in the bottle. In order to ensure the cleaning effect, the pure water pressure required for cleaning is not less than 0.4MPa. Bottle cleaning is often combined with filling and capping to form a "three-in-one" filling machine.

8. Sterilization: Pass the filtered material liquid through the UHT sterilizer to sterilize the material liquid. Sterilization conditions: 130-135°C, 4-6 seconds. When sterilizing, make sure that the steam pressure supplied to the sterilizer is not less than 0.8 MPa.

9. Pouring the bottle: Pass the hot-filled product through the bottle-inverting machine immediately, turn the bottle upside down, and let the residual temperature of the material liquid after filling sterilize the bottle and the cap to ensure the quality of the product.

10. Filling and capping: There are mainly two methods of aseptic cold filling and aseptic hot filling. In order to ensure the quality of fruit juice beverages, aseptic hot filling is often used. The requirements: the temperature during filling should not be lower than 90℃, and the temperature in the bottle after filling should not be lower than 85℃. It must be capped immediately after filling. When capping, adjust the proper torque of the capping head to ensure a tight seal. "Three-in-one" hot-filling machine for bottle washing, filling and capping.

11. Light inspection: Let the product pass through the light inspection machine to check whether the bottle has dirt, impurities, whether the bottle seal is complete, etc., to ensure that the qualified product enters the next step.

12. Cooling: Let the product pass through the cooling tunnel to make the temperature of the product drop to (38±2)℃ quickly. More damage. Less investment in hot-filling equipment.

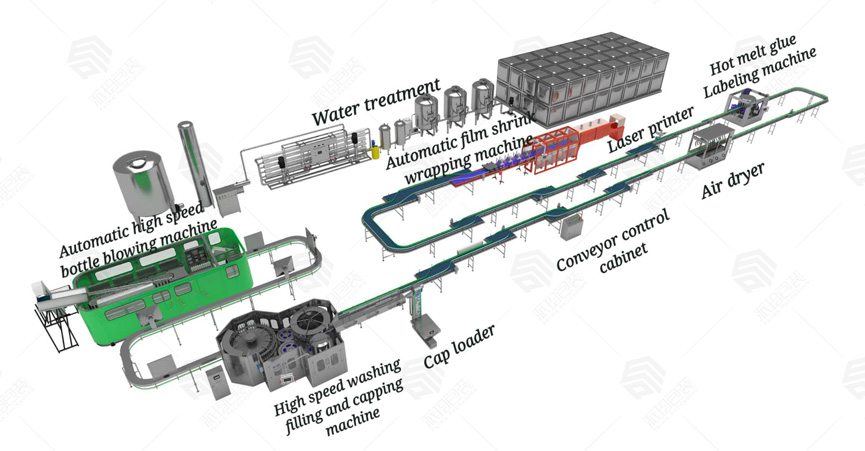

Full Production Line of Water Solutions

Complete Fruit juice production line

1. Bottle making system

pet preform→Autoloader→reheater →molding→ bottles

2. Water purification system

Source water tank →Source water pump→ Quartz sand filter→ Active carbon filter→ Ion soften machine→ Fine filter →Reverse Osmosis

→Ozone sterilizer → pure water tank

3. Juice CSD drink processing system

(1). High-shear emulsifying tank + Plate heat exchanger

(2). Mixing tank

(3). UHT sterilizer + homogenizer machine + Buffer tank

(4). Hot water system + Hot water tank

(5). CIP cleaning system

4. Bottle filling & packing system

Pure water tank→Bottle blower→Air conveyor →Washing, filling & capping 3-in-1→ Light check → Full-automatic labeling machine →Inkjet machine →Full automatic PE film packing machine→ warehouse

| Fruit juice Filling Machine Bottle Material: PET Bottle Cap: Plastic Bottle Volume: 100-2500ML Production Speed: 1000-36000bph Suitable Bottle: Height:170-320 Diameter:20-100 |

|  |

1.Except for the down framework, the transmission parts, and some parts that must be made of special materials. Other spare parts are made of stainless steel 304.

2.The roller bearing is made of stainless steel, the sealing ring is made of EPDM material, and plastic is made of UMPE.

3.The gripper is made of stainless steel, the position where hold the bottleneck is also made of stainless steel, compared with the traditional rubber gripper, it is much hygiene, durable, and no quick-wear parts, the screw parts of the bottleneck can avoid

being polluted by the rubber gripper.

4.The gripper equipped with a high-efficient spray nozzle can develop to any position of inwall of the bottle and can save rinsing water. There is a cover above the spray nozzle which can prevent water spilling, and there are regulatory recycle slot and recycle pipes under the nozzles.

5.Rinsing time can be guaranteed for 4 seconds.

6.By adjusting the height of the rotary parts to adapt for different bottle height

7.The motivation is derived from the driven system in the framework passed by gear.

8.The supply of rinsing water is controlled by a solenoid valve

|  |

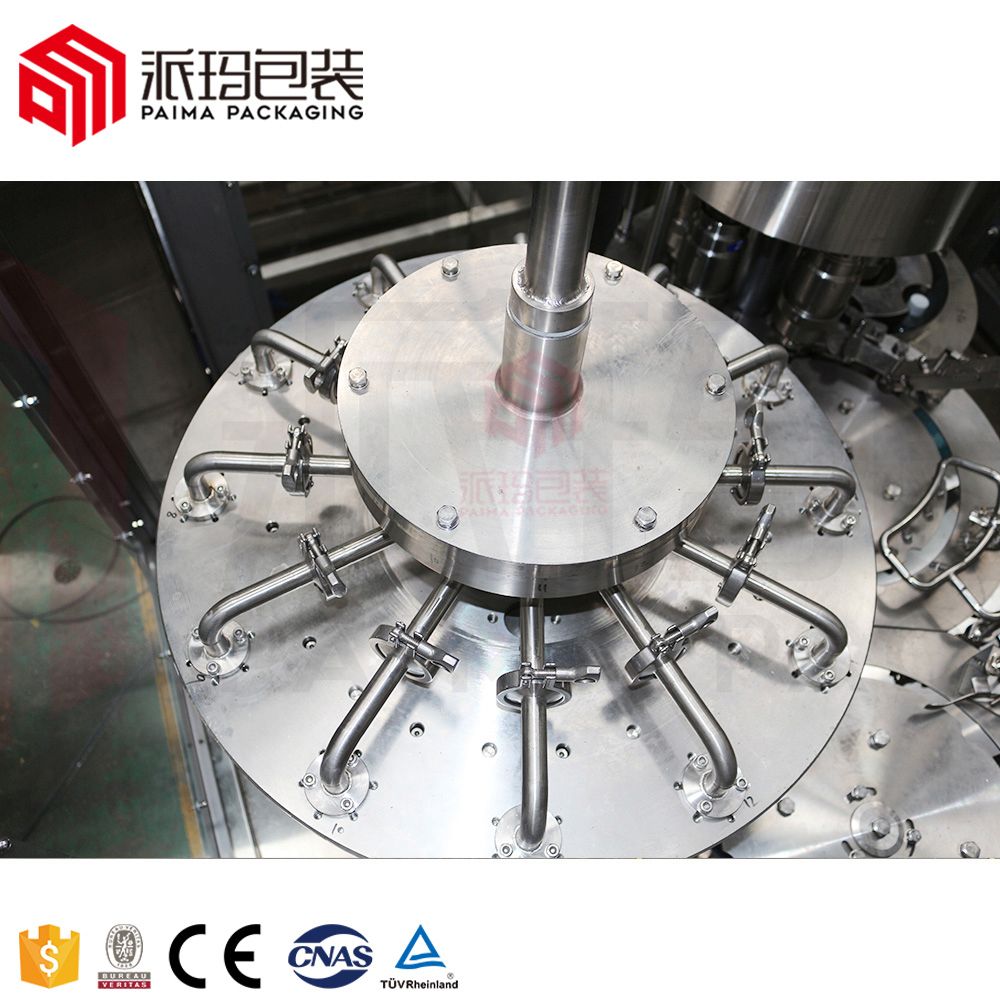

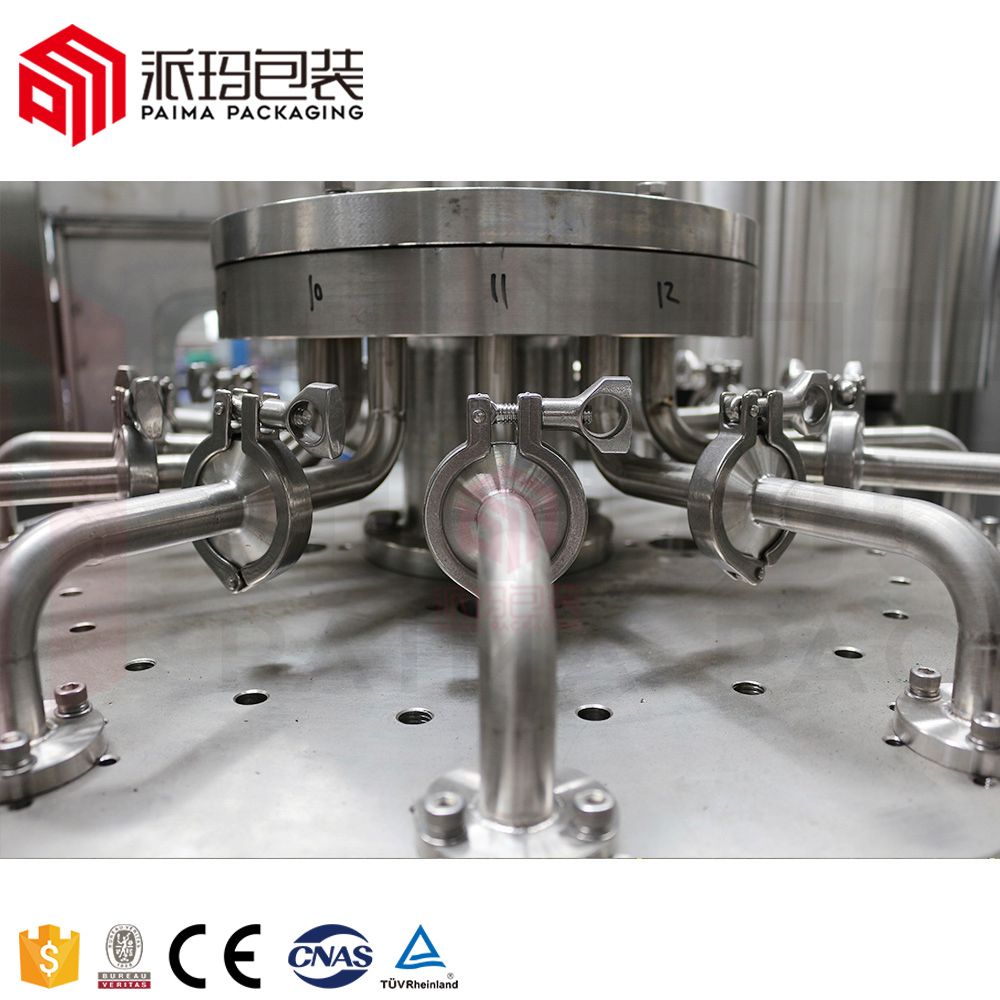

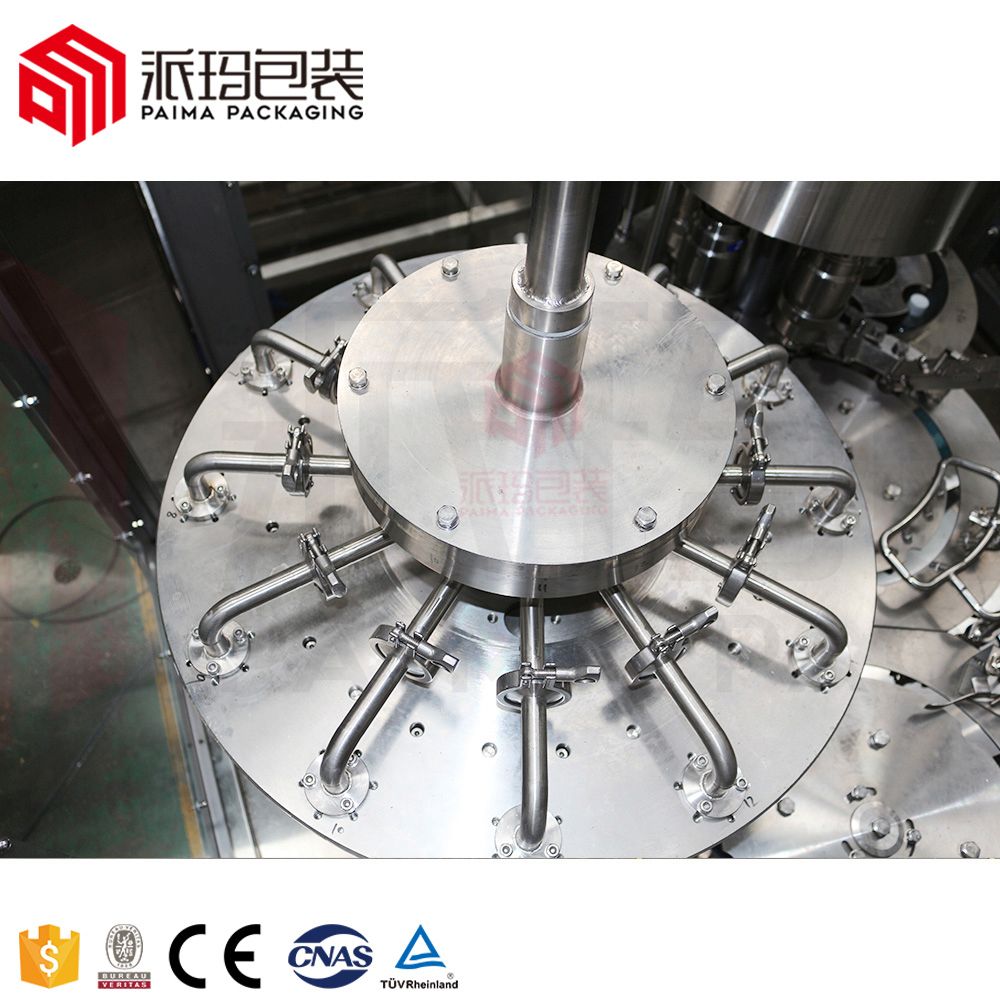

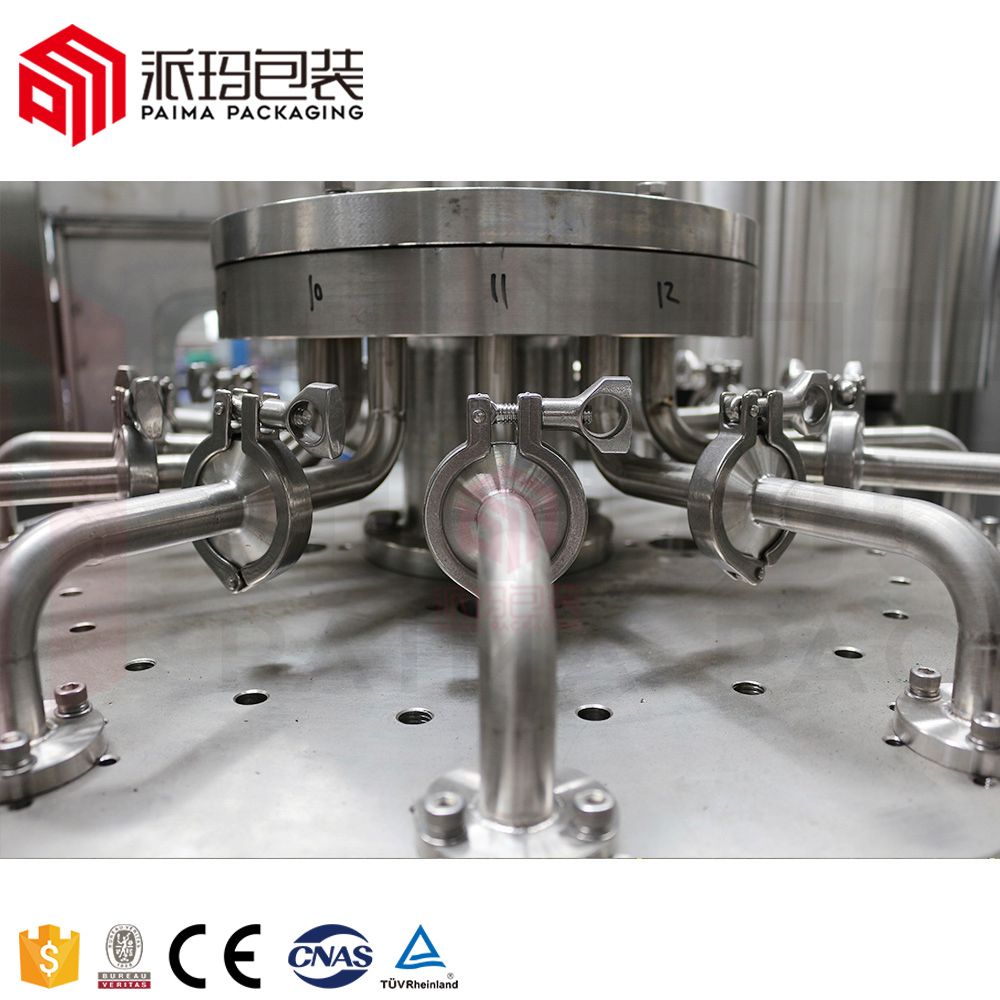

1. Adopted Germany anti-corrosion non-maintaining bearing that can reduce the pollution of filling to the environment.

2. The rotate plate is made of SUS AISI304, a large flat toothed bearing.

3. The pressure mechanical valve is introduced to the advanced foreign design with a fast filling speed, no hygiene corner pocket, a few sealing parts, and precise liquid level control. The whole valve is made of 304 stainless steel.

4. The filling system has a CIP circulation system to wash the pipeline. This system can clean the liquid pipe, liquid tank and filling valve, etc. effectively.

5. This filling system has an automatic temperature control system.

6. The filling valve opens and begins filling when the pressure is balanced between the inside bottle and liquid tank, the filling valve moves up and leaves the bottleneck when it finishes filling.

7. The liquid supply adopts the automatic pneumatic valve magnetic liquid-level switch to control the liquid tank automatically.

8. The motivation of the filler is derived from the driven system in the framework and passed by gear.

|  |

This unit is the highest degree of accuracy of 3 in 1 machine, it is important for the machine to run stably and the product quality. Characteristic of the screwing capper as follows:

1. Adopting the most advanced cap sealing technology. For example, I. the screwing capping head cam (the main parts which can assure the machine run stationary), while adopting technology, the expert improve the authenticity and stability of the machine focused on dynamics and kinematics. II. Screwing capping head (the main parts which can assure the capping quality), the expert improve the design of magnetic steel, this improvement can reduce the defective rate of capping better and the traditional character of easy to set and adjust the torque of screwing capping head.

2. The screwing capping head is a dual-purpose design; it is suitable for flat caps and sports caps.

3. The device which can take out the reverse cap and prevent the reverse cap from passing is settled in the cap-falling guide.

4. A group of photoelectric switches is settled on the cap-falling guide. The machine will stop when there is no cap on the guide.

5. A bottle inlet detect switch is settled on the screwing capper.

6. There is a cap-lock cylinder in the joint between the cap-falling guide and poking cap plate. It is realized that no feeding no cap.

7. By adjusting the height of the rotary parts to adapt to the different bottle heights.

8. The motivation of the screwing capper is derived from the driven system in the framework and passed by gear.

9. The main parts of the screwing capper are processed by the digital-control processing center

10. The new capping head can make capping in both clockwise and anti-clockwise directions; It will make the cap correctly fix to the neck, correctness 99.999%.

Customer Cases

For nearly 12 years, Paima Packaging has provided bottling & packing equipment of liquid solutions to companies all over the world, water bottling lines, juice filling lines, carbonated soft drinks turnkey projects, oil and soda water bottling line, and labeling and packing machinery. Paima PacKaging offers complete filling and packaging solutions for the beverage industry and excellent lifelong time service.

We have a customer from Ethiopia who ordered a complete water line from water treatment to the back-end packaging equipment. And last year, when we went to Ethiopia to participate in the exhibition, we especially visited them. These are the real pictures we took from our customer's factory.

| ||

|  |  |

Our cooperation partner

Packing and Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient, and efficient packaging services will be provided.

| ||

|  |  |

ABOUT PAIMA:

Paima Packaging is a professional manufacturer that consists of research&design, production, and marketing in one unit, It is a professional manufacturer of beverage filling and packaging production line and packing material Since the establishment, we Rely on the ideal " faith and Steadfast, pursue remarkably" we insist on the realistic policy and show the perfect service to our customer, we always design and update our machine quality based on the ended user's actual use situation, due to our hard-working, we help our customer save a lot of labor cost and enhance their market competitiveness.

Due to the advanced technology, the fine processing equipment, we are already popular and reliable to our customers with its machine quality and faith, we welcome the customer from all around the world visit our company, thank you for your trust and help honestly, we believe mutual cooperate and respect mutual benefit and treat the person faithfully, in the end, we will succeed together.

FAQ:

1. HOW TO FIND US ?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufacturers and not traders

● Visit the exhibition in different countries

● Send us a request and tell us your basic inquiry

● Our sales manager will reply to you in a short time and add an instant chatting tool

2. YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fulfill your request and you interested in our products, you may pay a visit to Paima Machine site

● The meaning of visiting supplier, because seeing is believing, Paima Machine with own manufacture and developed& research team, we can send you engineers and make sure your after-sales service.

3. HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on-time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facticity of our bank account.

4. HOW TO ENSURE THE QUALITY ?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure stable running in the customers' factory

5. THE AFTER-SALE SERVICE OF PAIMA MACHINE ?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to the customers' factory to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customer's project.

want to know more about machines ? contact us now