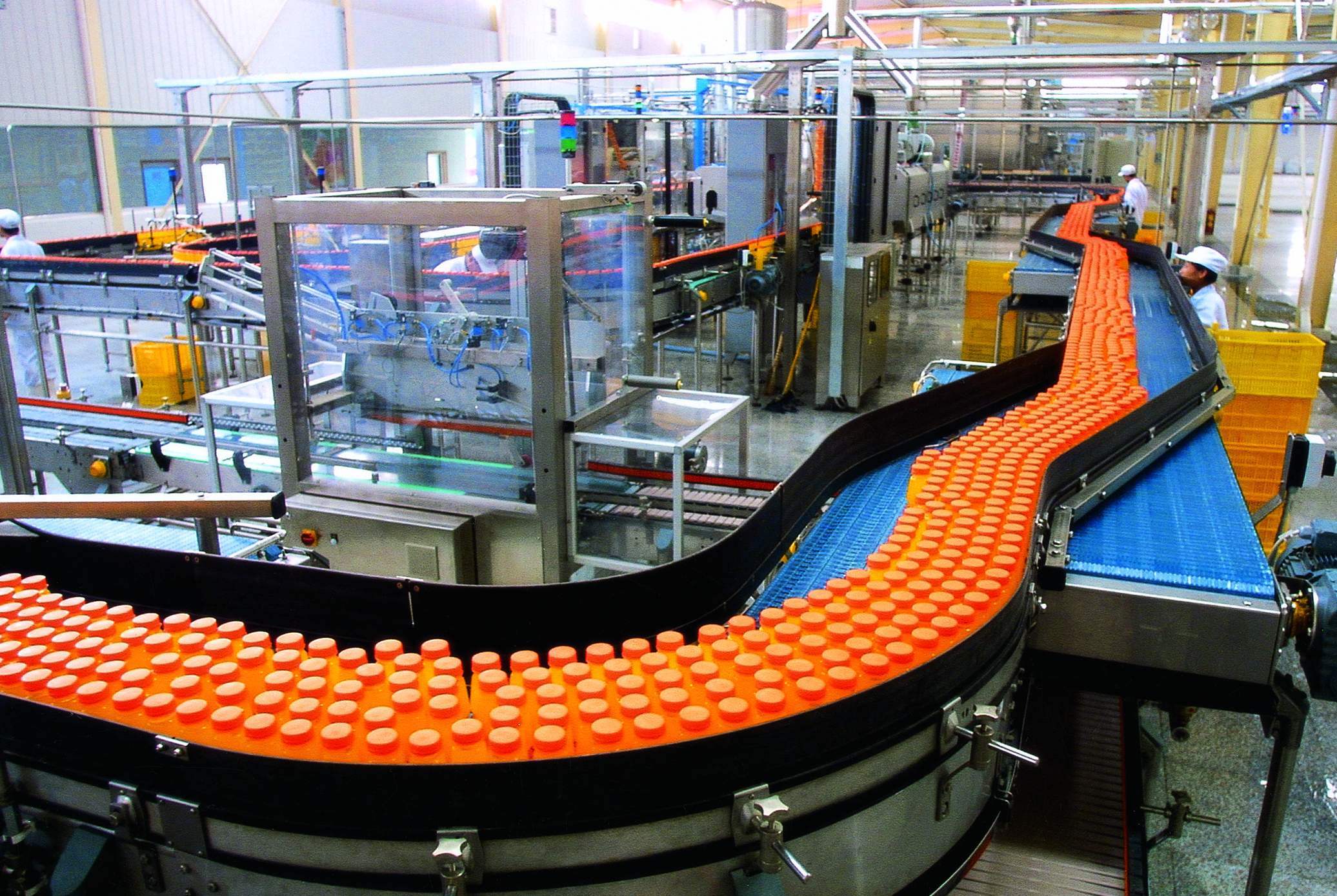

The aerated carbonated beverage production line realizes bottle punching, filling, and capping on one machine. The whole machine has a scientific and reasonable design, beautiful appearance, complete functions, convenient operation and maintenance, and a high degree of automation. The machine adopts advanced technology from Italy and Germany. Fast filling speed and stable liquid level control. Such as no bottle no filling, flushing or filling burst bottle when the filling valve will be automatically closed, and automatic flushing and other advanced self-control technology.

Working principle:

The bottles are passed through the wind feeder and then transferred to the bottle flusher of the 3-in-1 machine through the bottle dial star wheel. The bottle flusher is equipped with bottle clamps on the rotary disc, and the bottle clamps hold the bottle mouth and flip 180° along a rail to make the bottle mouth down. In the specific area of the flushing machine, the flushing water is sprayed from the nozzle of the flushing clamp to rinse the inner wall of the bottle. After rinsing and draining, the bottle is held by the bottle clamp and then turned 180° along the guide rail so that the bottle mouth is up. The washed bottles are exported by the bottle flusher through the bottle paddle star wheel and transferred to the filling machine. The bottles entering the filling machine are caught by the bottle* plate and raised by the cam, and then the filling valve is topped off by the bottle opening. The filling is done by gravity filling. After the filling valve is opened, the material passes through the filling valve to complete the filling process. After the filling is finished, the bottle mouth drops away from the filling valve and the bottle enters the capping machine through the transition toggle wheel of the bottleneck. The stopper on the capping machine snaps on the bottleneck to keep the bottle upright and prevent rotation. The capping head keeps rotating and rotating on the capping machine, and under the action of the cam, it can grasp the cap, set the cap, spin the cap and take off the cap to complete the whole capping process. The finished bottles are transferred from the capping machine to the bottle conveying chain through the bottle discharging toggle and then transferred out of the three-in-one machine by the conveying chain.

Features of the aerated carbonated beverage production line.

1、Adopt bottle lifting cylinder, oil nylon gear drive, low noise, smooth running of the whole machine.

2、Adopt a magnetic torque type cap screwing head to realize the function of cap grabbing and cap screwing. The unscrewing torque is steplessly adjustable and has the function of constant torque screw sealing plastic cap, and it does not hurt the cap, and the sealing is tight and reliable.

3、Horizontal rotary pneumatic capping device, with no damage to the surface of the cap, the lack of cap in the hopper to signal automatic replenishment, and other functions.

4、The whole machine adopts PLC computer program control and human-machine interface touch screen button, with automatic control of liquid level in the material cylinder, no bottle without canning, no bottle without cap and other functions, and has the functions of stopping for bottle misalignment by dialing the bottle star wheel and stopping for lack of cap in the cap slide.