want to know more about machines ? contact us now

Opp labeling machine, or hot melt opp labeling machine is suitable for labeling opp material labels, on different volume and shape of bottles. No matter the bottle is round,square, or special shape, our machine is able to label it.

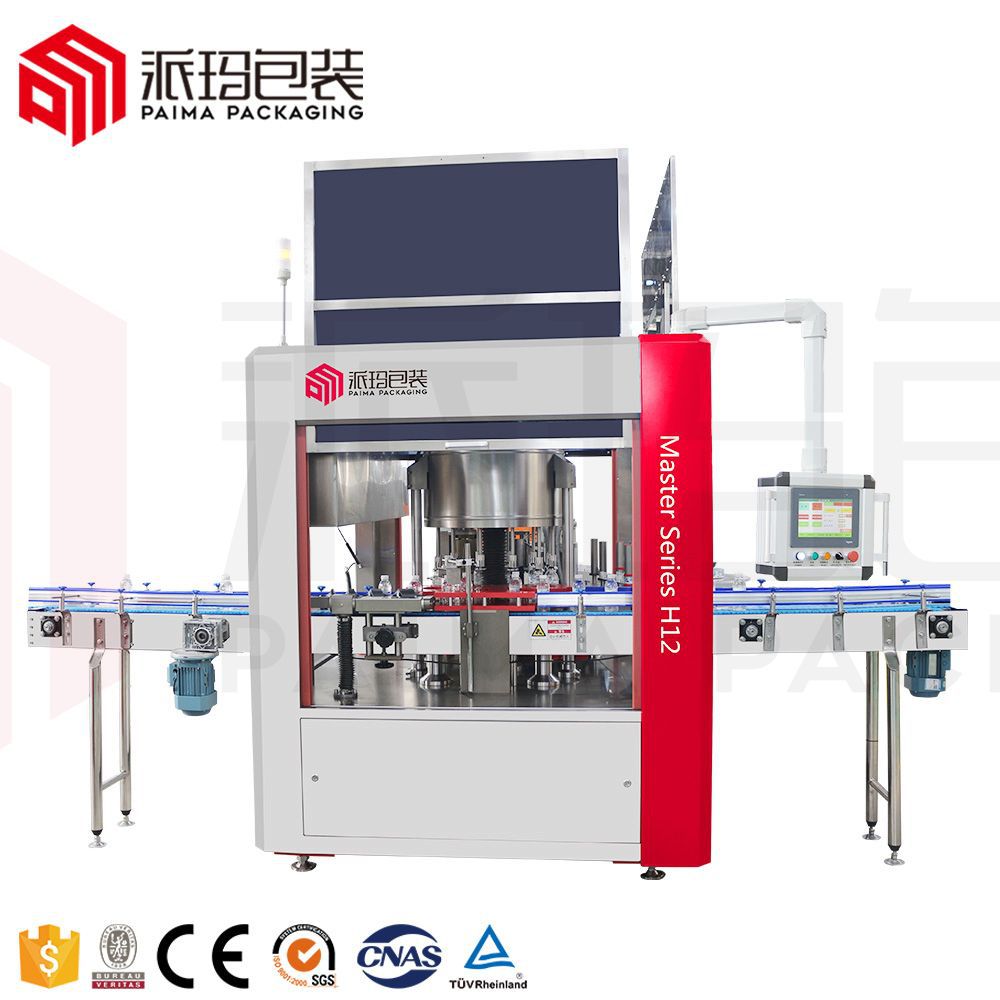

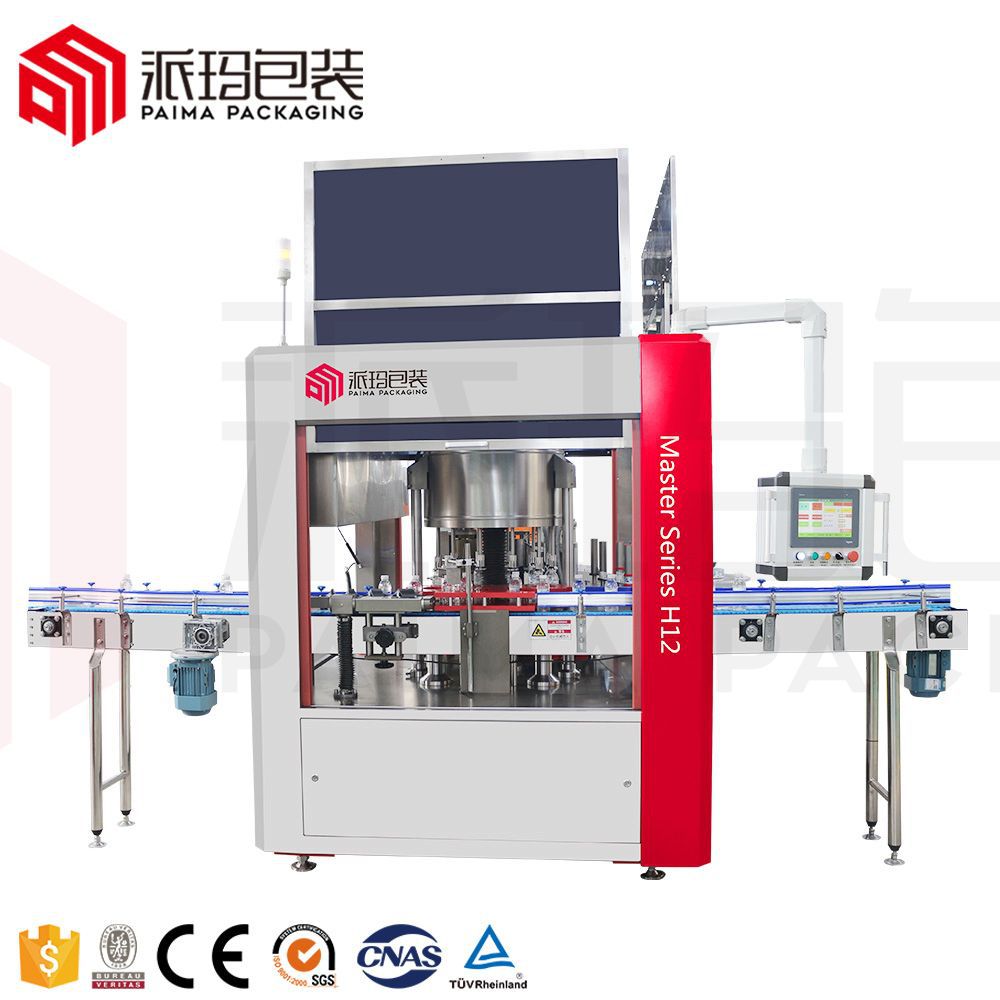

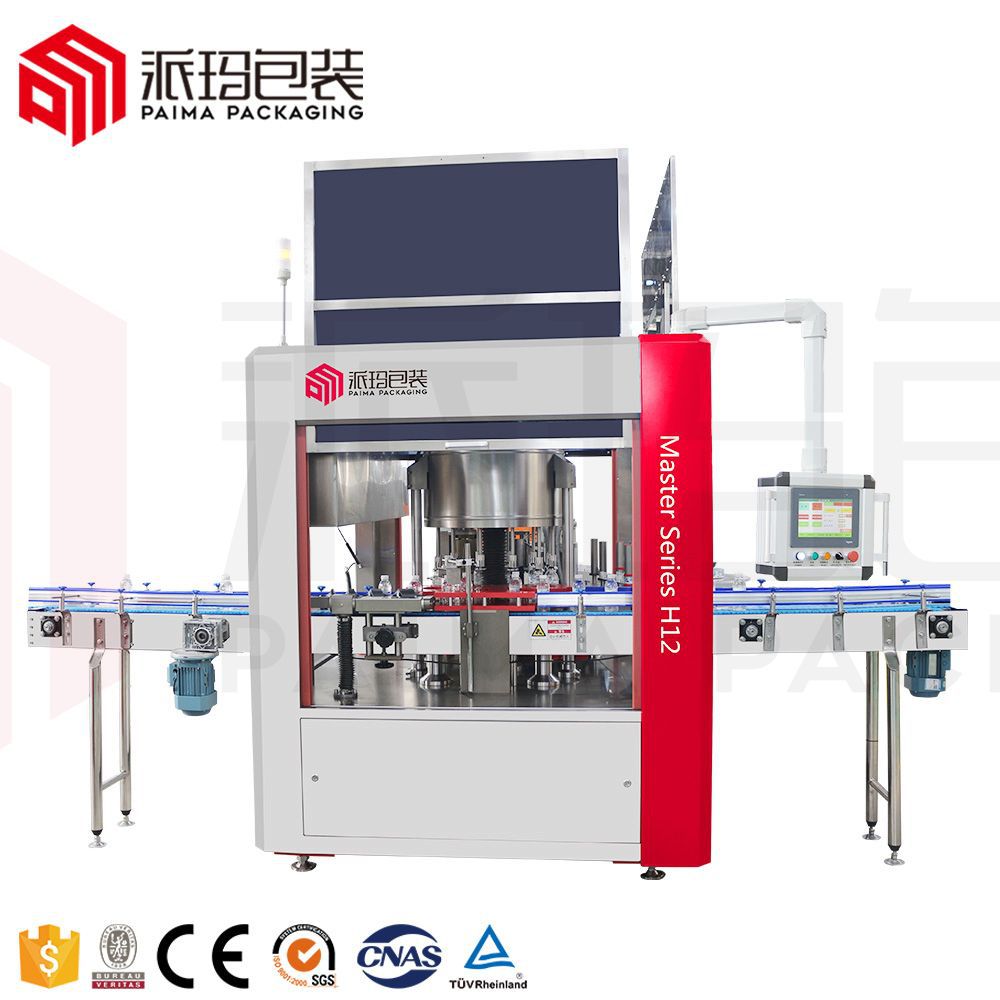

Automatic Rotary Opp Hot Melt Labeling Machine

Introduction

Opp labeling machine, or hot melt opp labeling machine is suitable for labeling opp material labels, on different volume and shape of bottles. No matter the bottle is round,square, or special shape, our machine is able to label it. It is easy to operate and convenient to change the mould. It's cable to work with PET blwoing machine, filling machine, code printung machine, water treatment ,ect. In addition,the label cost is comparatiely lower, it can meet the requirements of those users who have diverse kinds of the containers.

Feature

1.Auto cutting and Sticking circle or half circle of bottle. Auto melting and attaching glue on top and rear of the label , glue auto recycling .

2.Variable speed control system, synchronous automatic detection system, automatic adjust production speed, Always make the labeling machine at best production speed

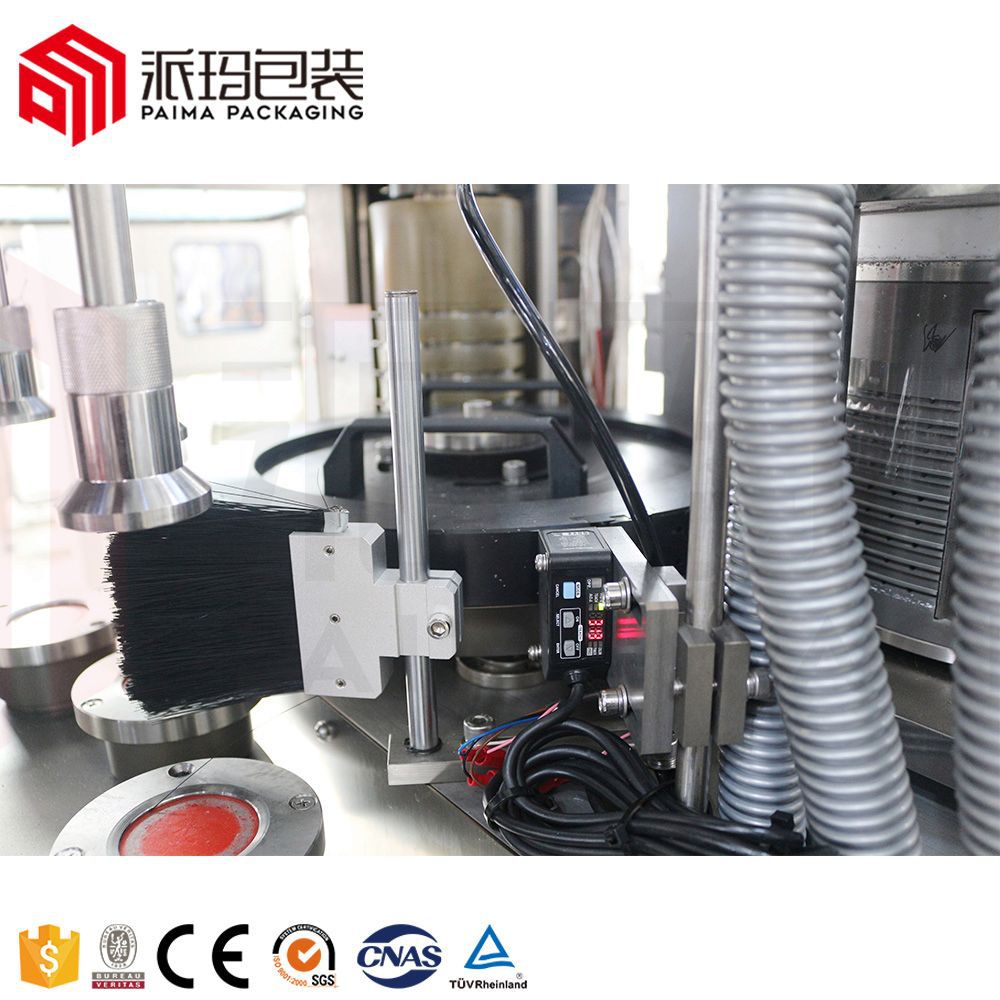

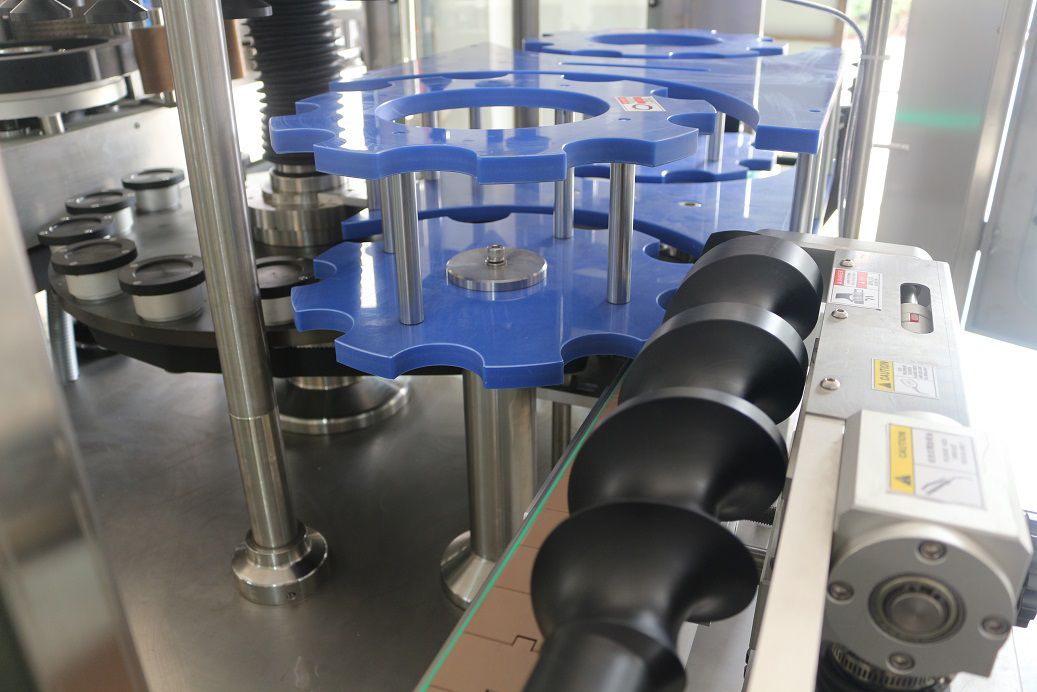

3.Star Wheel separation and feeding ,correlation design transmission mode high-speed labeling, stable precision.

4.Servo motor synchronous tracking, with special designed vacuum drum adsorption, labeling precise and stable

5.Abnormal situation, this machine has safety device, automatic stop immediately.

6.Following conditions the machine will automatically stop and alarm:

(1) Label is not labeled on bottles

Label sticker failure

Label is about to run out

Abnormal bottle feeding

(2)Abnormal bottle out

(3)Abnormal bottle jam

7.The whole machine centralized lubrication system, easy to clean, lubrication and maintenance.

8.Techmach electronic automatic rectify guide system, digital electronic eye for ultrasound method.Non-contact electric eye, automatically adjust the label location. (optional).

9. Label top and end difference within 2mm ( without Techmach), 1mm (with techmach)

Technical Parameter

No.

Item

Parameter data

1

Power supply

Three-phase 380V 50 Hz 8000W

2

The total length of equipment

3000mm (conveyor length 3000mm or can be regulate base on your product lines)

3

Equipment width

2500mm

4

Conveyor speed

30m/min (the speed of the transmission lines can be adjusted according to actual production)

5

The method of speed adjustment

uninterrupted - adjust rate

6

The largest Speed of labels feed

maximum speed of 100 meters labels / min

7

The largest speed of labeling

12000 PCS/H

8

Labeling accuracy

± 1mm

9

Integrated Labeling accuracy

± 1mm

10

Product Size

500ml

11

Maximum label width

150mm

12

The maximum length of label

500mm

13

The maximum diameter of label

600mm

14

Paper core diameter

152 mm

15

Labeling glue

leading and trailing edge gluing with hot melt

16

Gluing temperature

120~160℃

17

Type of label

opp label 、paper-plastic composite film label、paper label

18

Labeling workstation

12 per cycle

19

The quantity of labeling mold

one suit (to be satisfied with one product, each mold contains infeed worm 、infeed starwheel 、discharge starwheel、 position bottle and so on )

20

Machine weight

about 3000 Kg

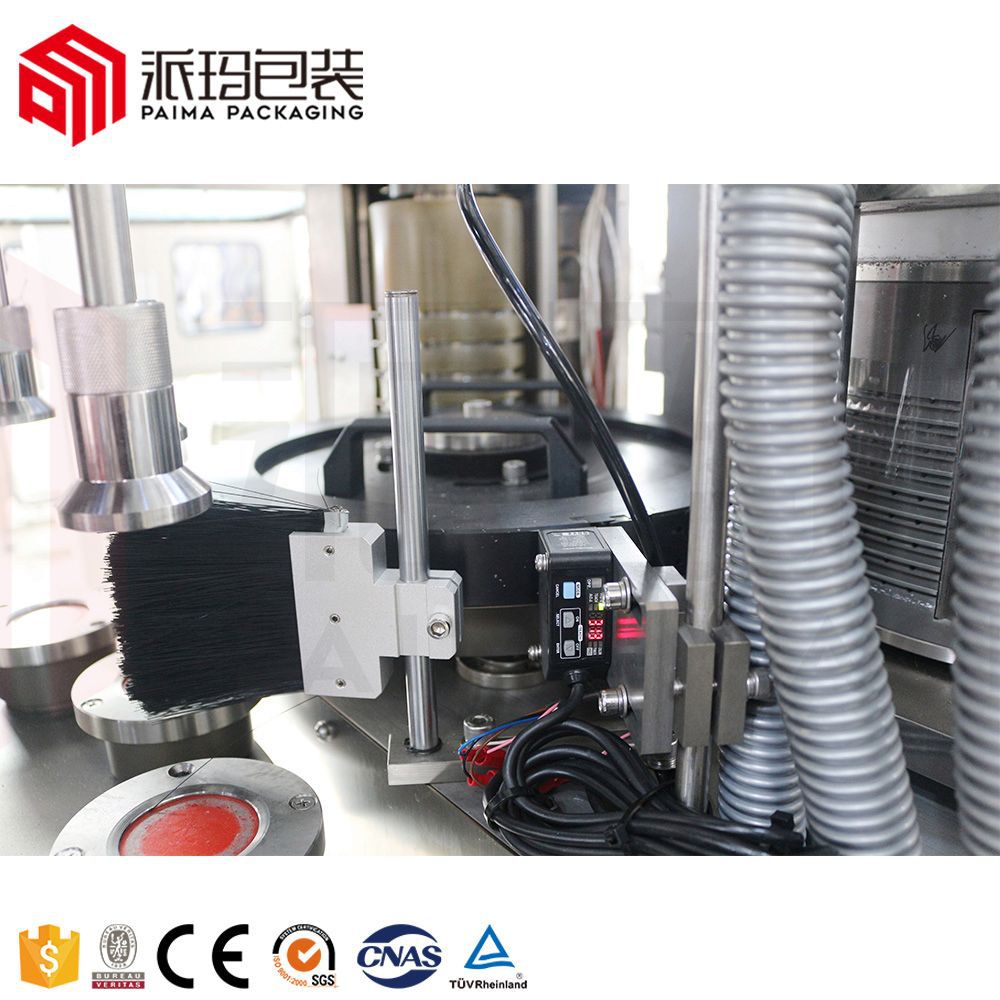

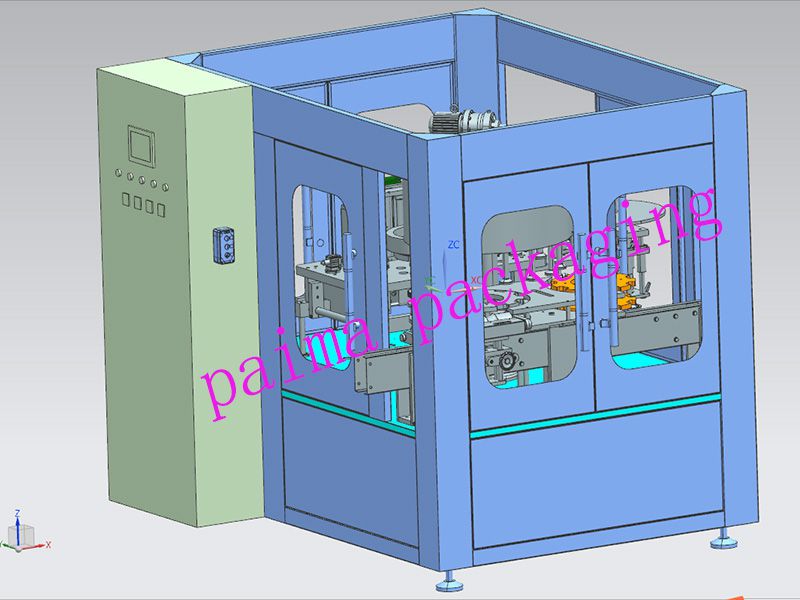

Detail Show

|

|

|

|

|

|

want to know more about machines ? contact us now