want to know more about machines ? contact us now

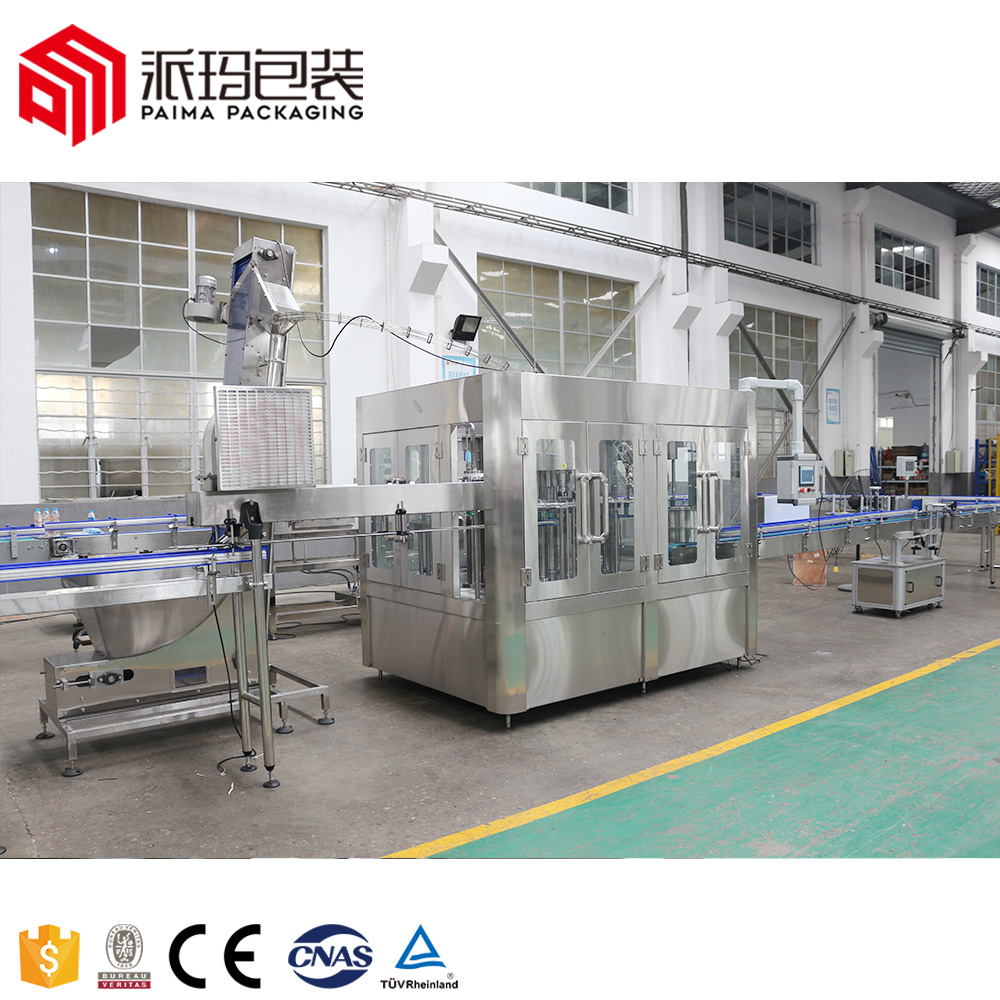

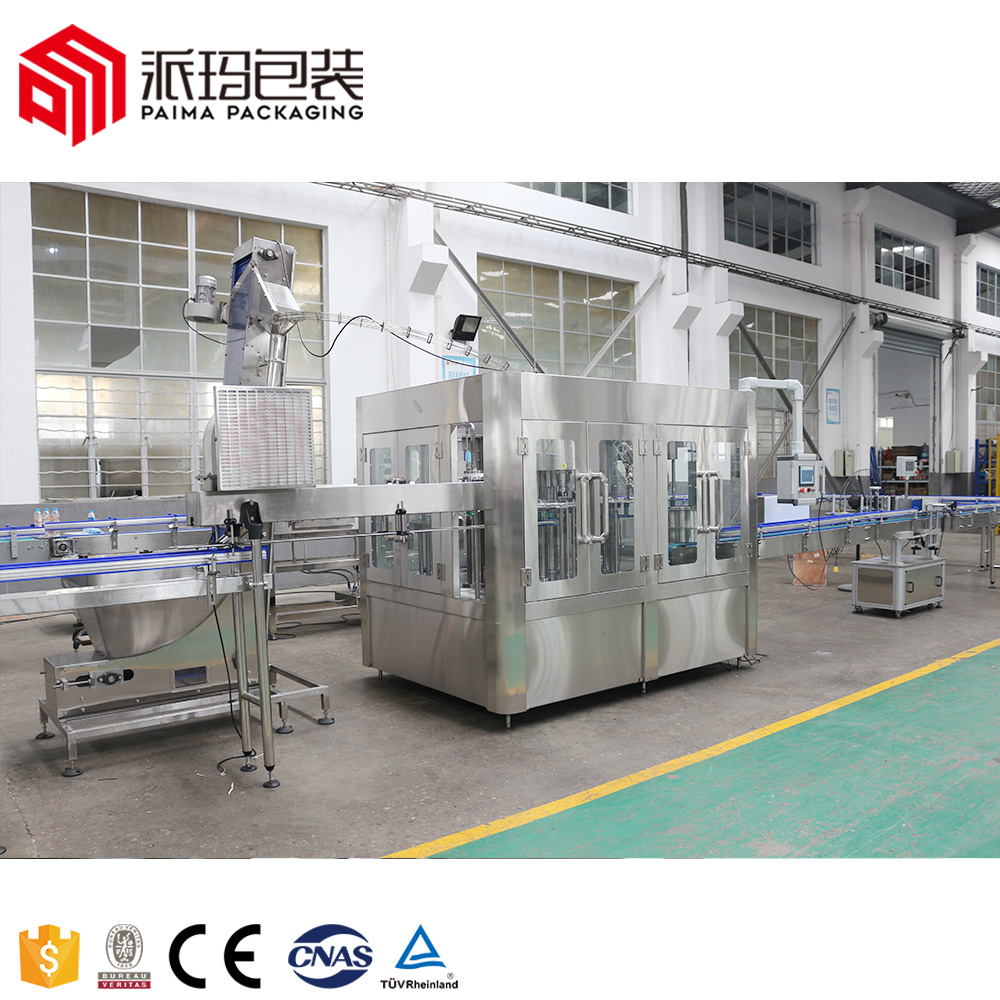

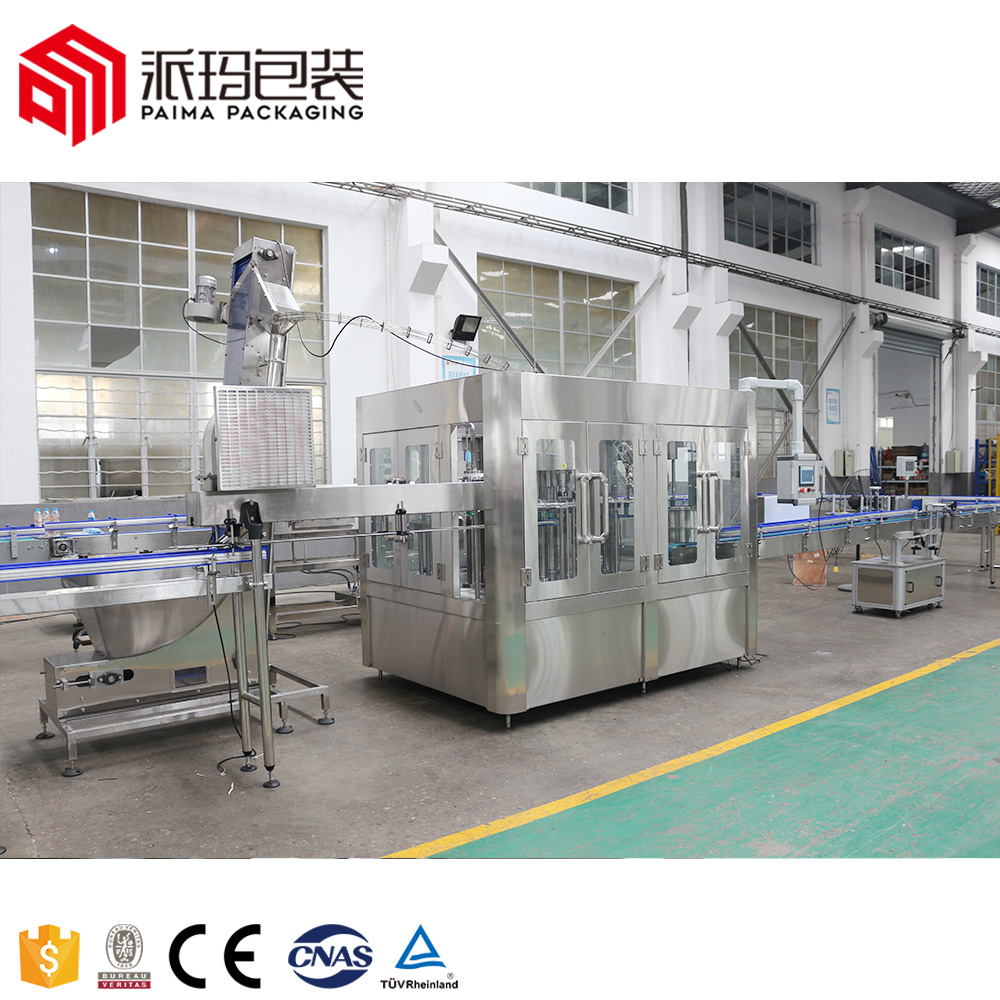

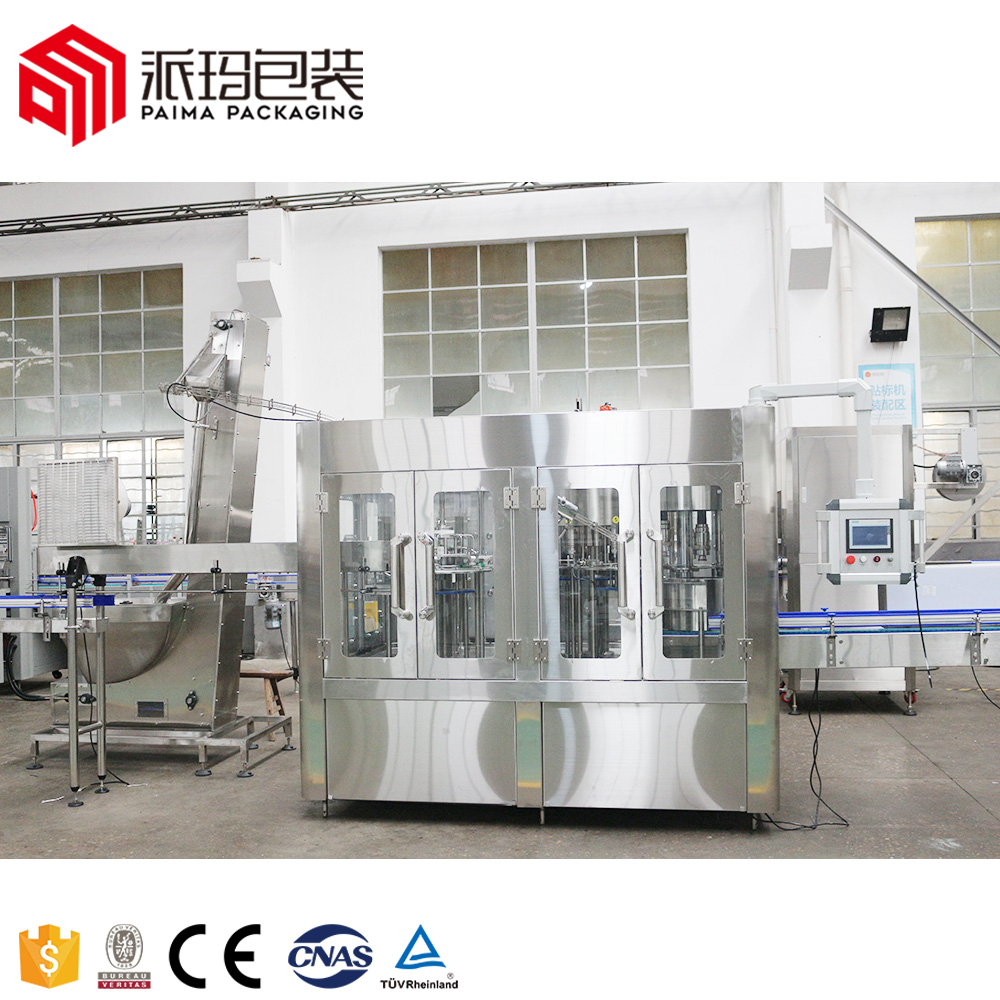

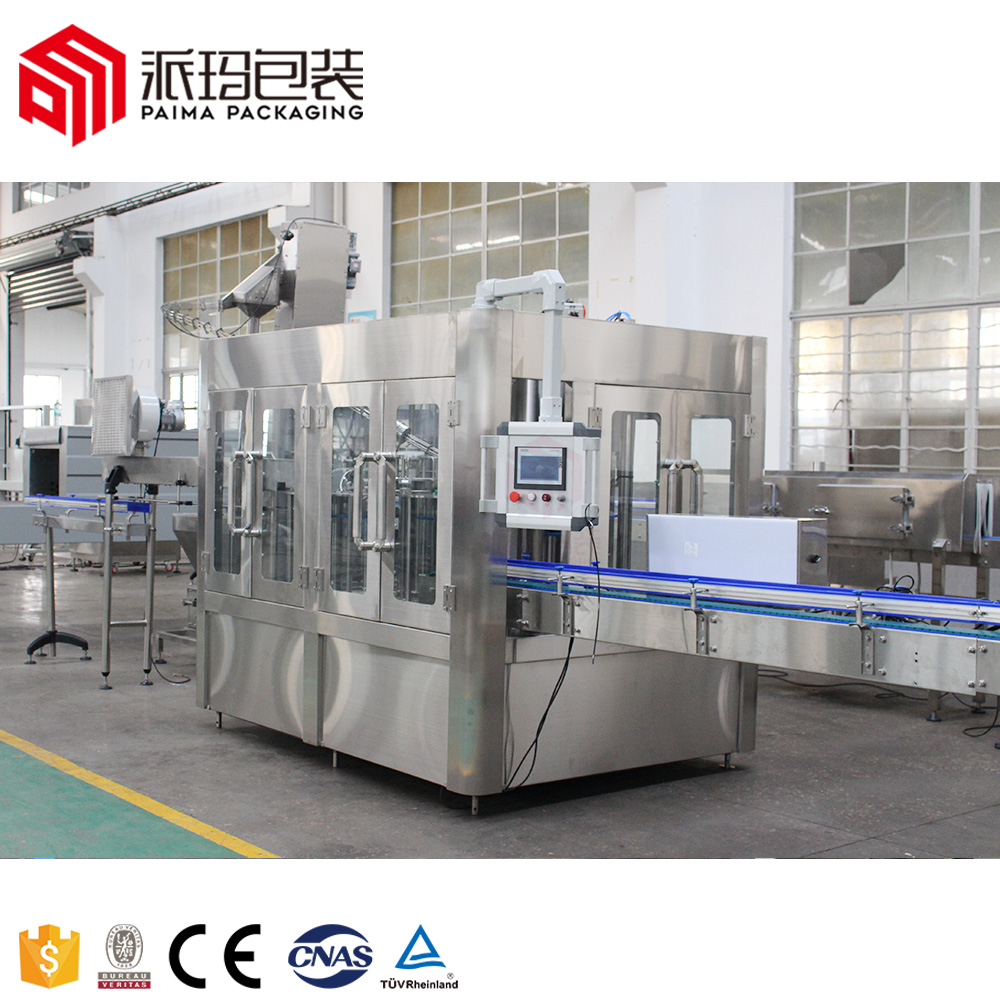

This Machine is mainly used in water filling operations, the three functions of bottle washing, filling, and capping are composed in one body of the machine, the whole process is automatic, it is conveniently turned to adjust the machine to fill various types of bottles, the filling operation is faster and more stable due to the advanced filling valve technology, The famous brand programmed controller (PLC) is adopted to control the machine runs automatically .it is a piece of ideal preferred equipment for beverage makers.

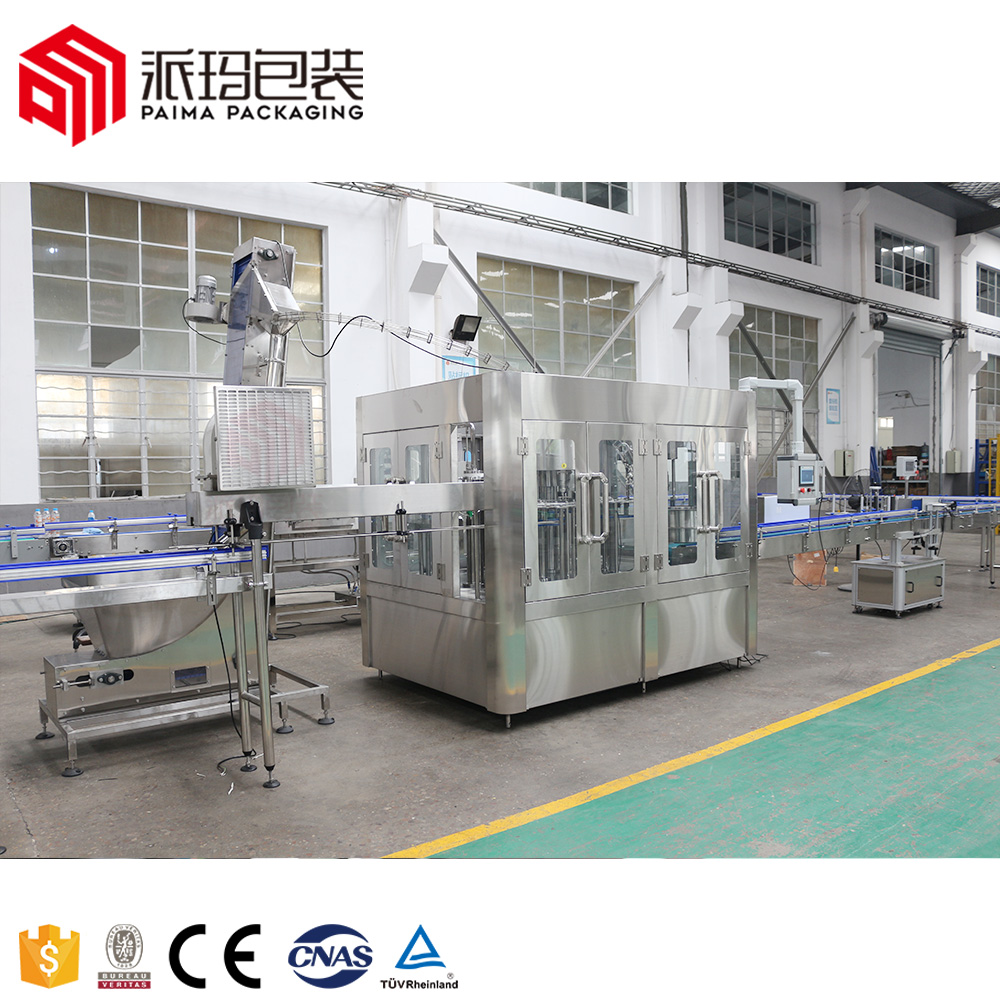

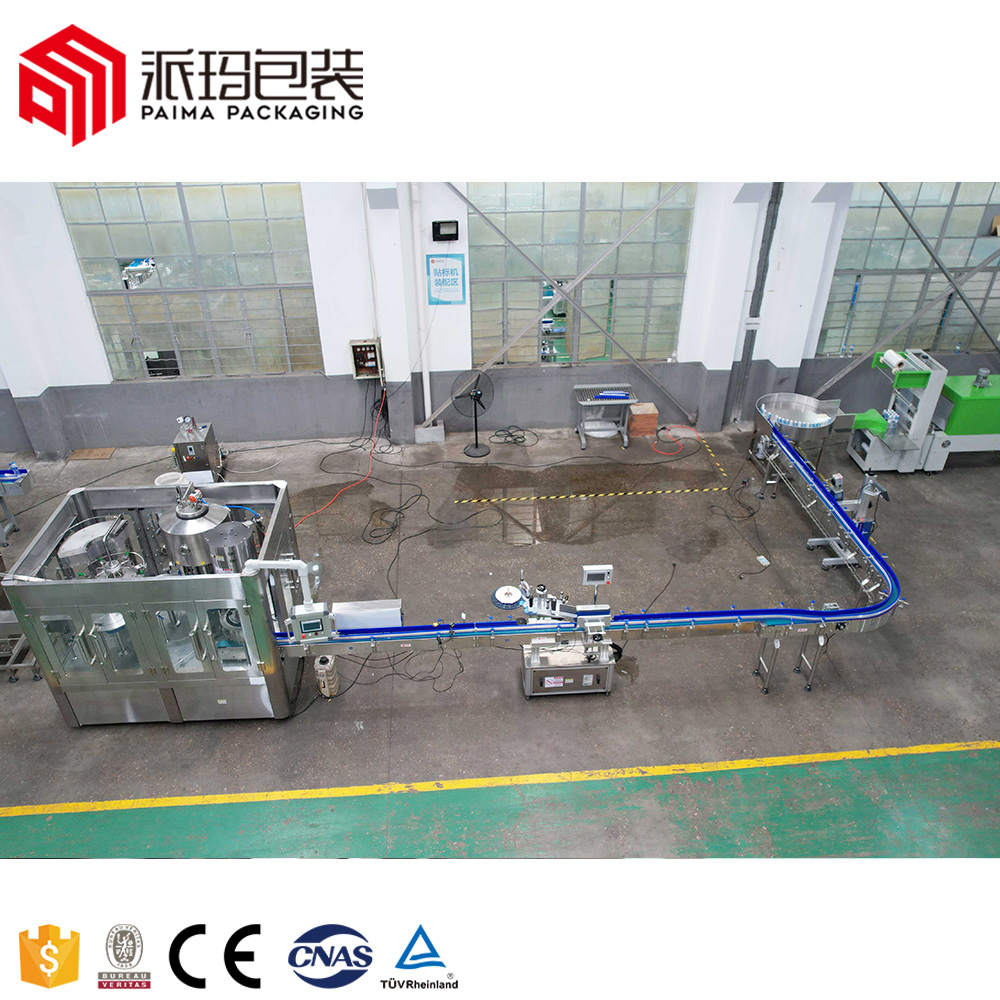

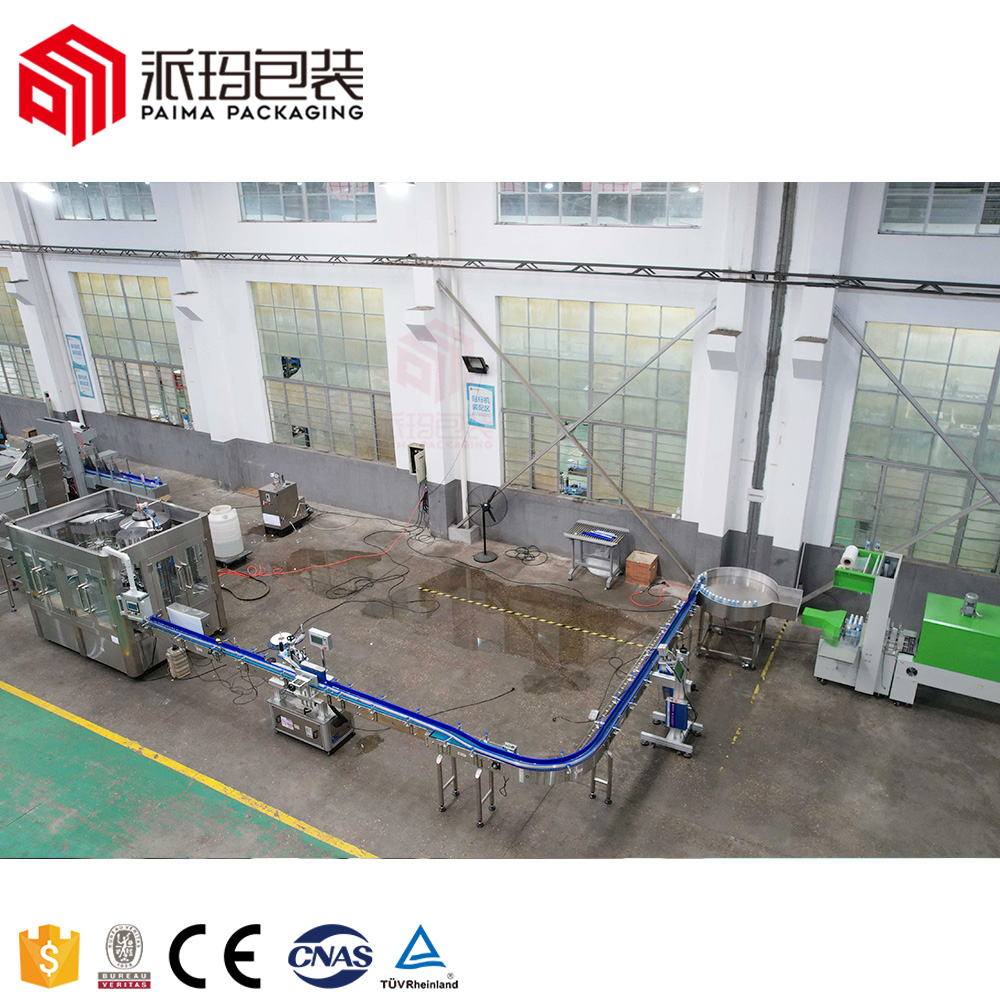

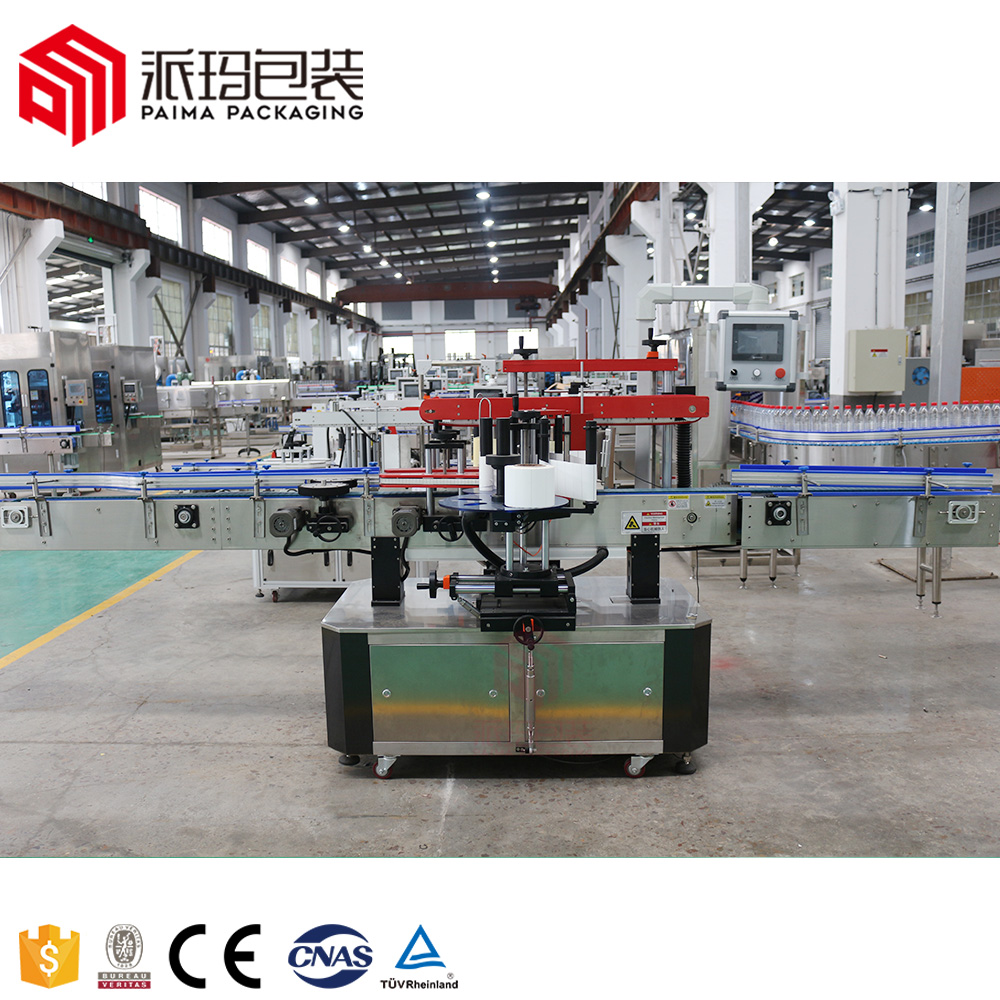

This series of bottled water production lines are mainly used for non-aerated drinks such as mineral water, pure water, non-gas wine drink, and so on, with a capacity of 2000-3000BPH based on 200ml to 2000ml. This small and start-up water production line is composed of a blowing machine, water filling machine, water purification station, labeling machine, and packing machine, all the machines you ever need for starting your new water business. The machine's special design will shorten the time for the water to contact the outside, Reliable Machinery is dedicated to presenting the best machines with clear advantages and strengths.

Suitable for water filling, widely used in the bottles packing on 0.2L-2L small scale bottles,

√√ Brand: Reliable Machinery-- Automatic Filling Machine

√√ Application: Pure water, Mineral water, Alkaline water, Springwater

√√ Capacity:2000BPH Warranty:2 Years

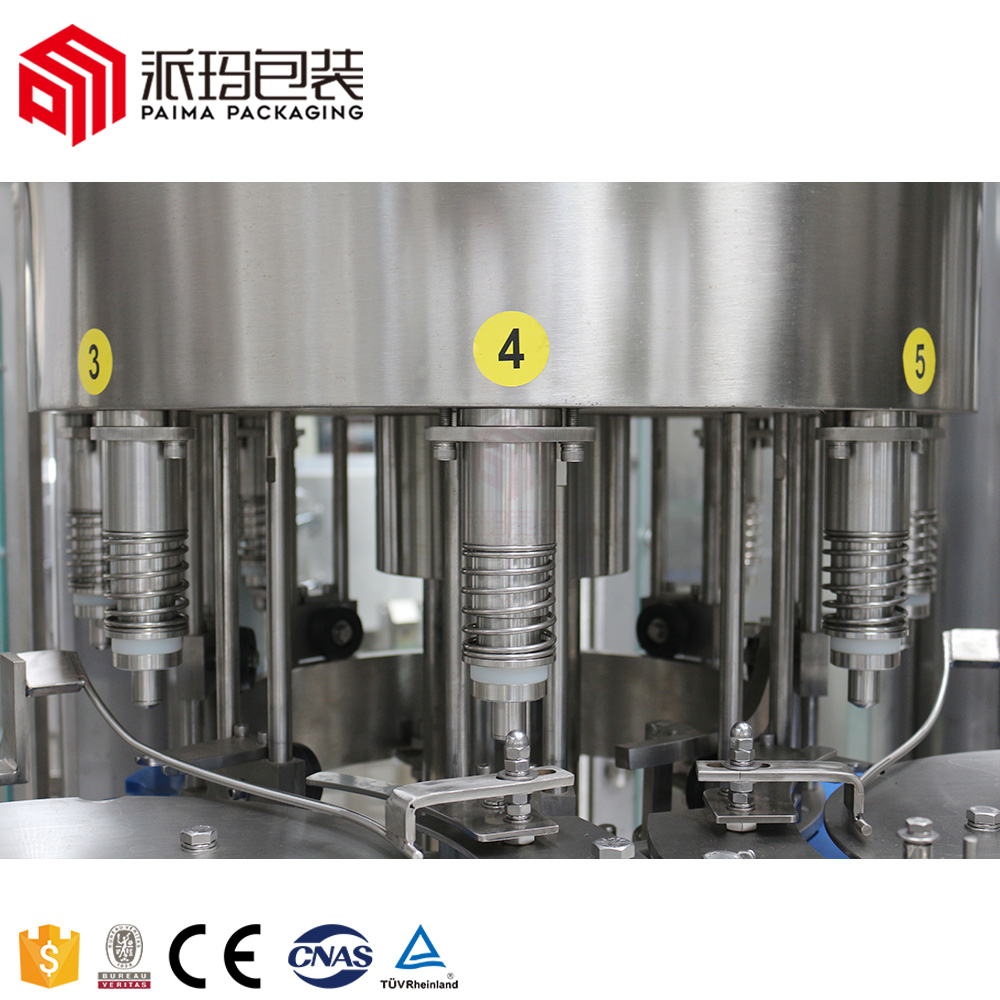

√√ 3 IN 1 Rinsing, Filling, Capping integration machine, 8-8-3 heads

√√ Intelligent SIEMENS PLC control and interface screen, automatic easy operation

√√ Bottles transmission by flat conveyor made in Stain Steel 304, ensure quality

√√ Compact structure, simplified operation, good performance

√√ Servo motor and Frequency convertor, stable operation, and fast

| Function :Washing / Filling / Capping System | |||

| Suitable for: PET bottles with screw cap | Bottle sizes : 250ml ~ 2L | ||

| Filling system: Gravity filling | Capacity: 2000 ~3000BPH | ||

| Application: still water, pure water, RO water, mineral water, sparkling water, etc. | |||

| Name : 2000BPH Mineral Water Filling Machine | |

| Model | CGF8-8-3 |

| Capacity: (for 500ml) | 2000 -3000 Bottles/hour |

| Suitable bottle shapes | PET Circular or Square |

| Bottle diameter | Dia50 ~ Dia115mm |

| Bottle height | 150 ~320mm |

| Compressor air | 0.3 ~0.7 Mpa |

| Washing medium | Aseptic water |

| Rinsing pressure | >0.06Mpa <0.2Mpa |

| Application | Still water / Pure water / Mineral water |

| Total power | 4.4kw |

| Overall dimensions | 2.3X1.9m |

| Height | 2.3m |

| Weight | 5500kg |

CHARACTERISTIC FEATURES

The machine body and all pipes are made of stainless steel 304.

The motor for the cap unscrambles is from a famous brand instead of a simple stirring motor like others.

Strong stainless iron as the door stopper instead of the common magnet to make sure the doors will be safely opened and closed.

Additional High stability handle, exclusive with us.

Free bottle shape design.

Fully transparent manufacture progress tracking.

Industry-leading production environment and standard production requirements.

Strict selection of high-quality materials, fine workmanship, and long service life.

STANDARD FEATURES

In order to make sure that the bottles are stably conveyed to the next part of the production line, we side-cover the whole bottle flat conveyor with stainless steel.

The conveyor belt is held by the roller for stable operation.

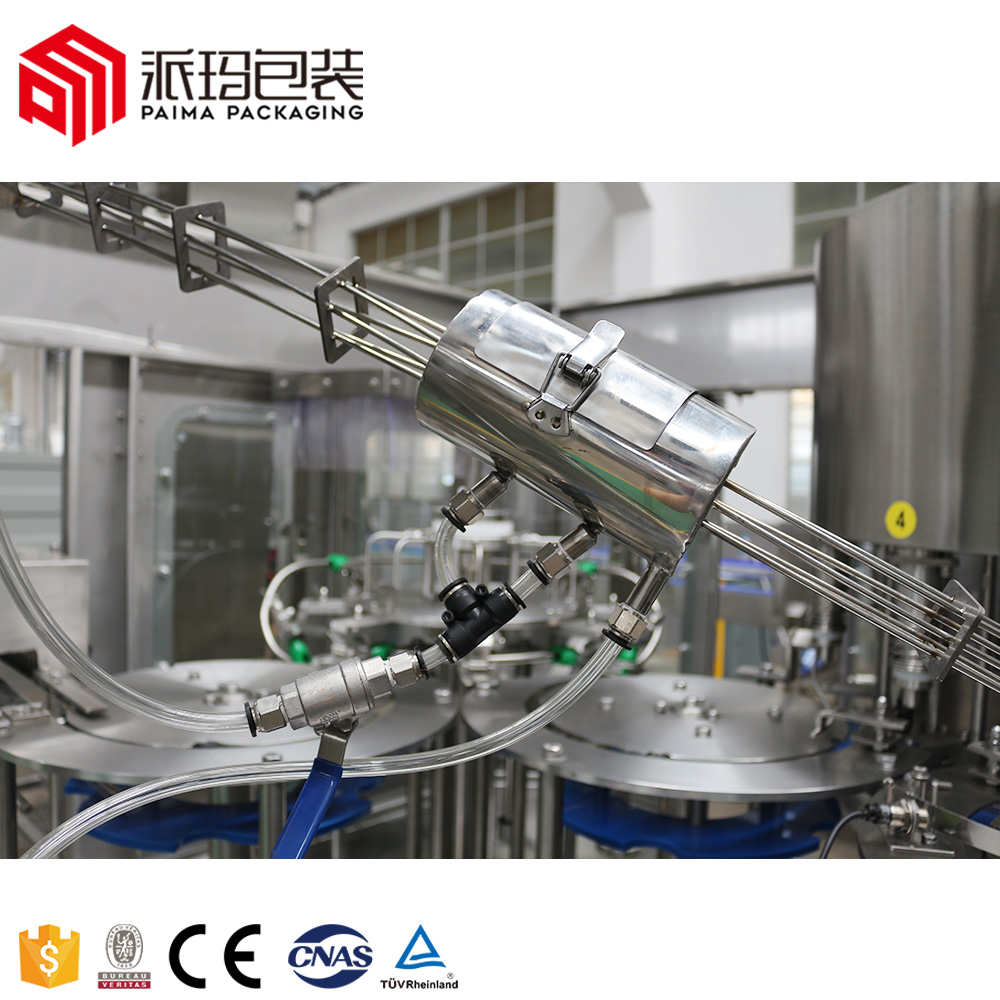

High-quality Water and oil separator from brand AIRTECH.

Our control panel is SIEMENS and the switch is Schneider.

High-efficiency, energy-saving, economical, safe, and environmental-friendly.

Strong production capacity and superb technology.

Perfect manufacture and quality inspection equipment.

Longer service life and lower machine maintenance costs.

Spare Parts Stock Service and 2 years warranty.

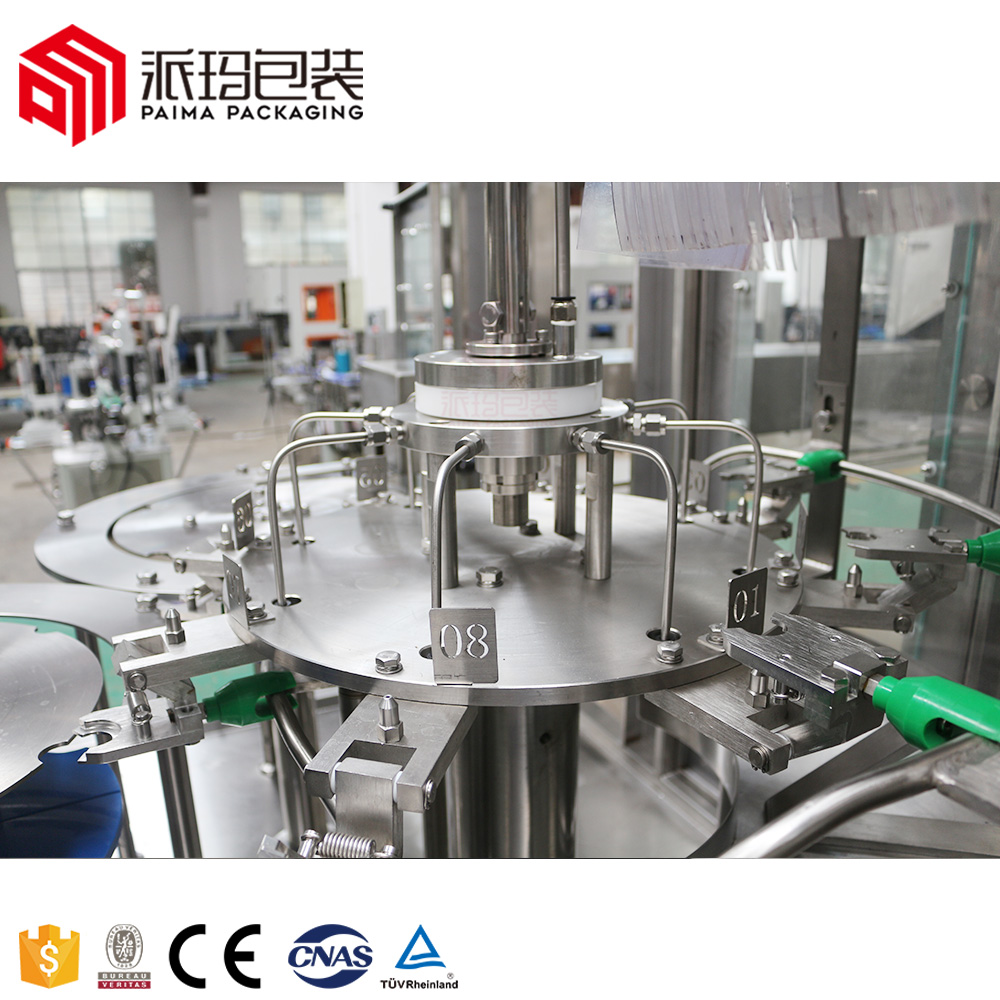

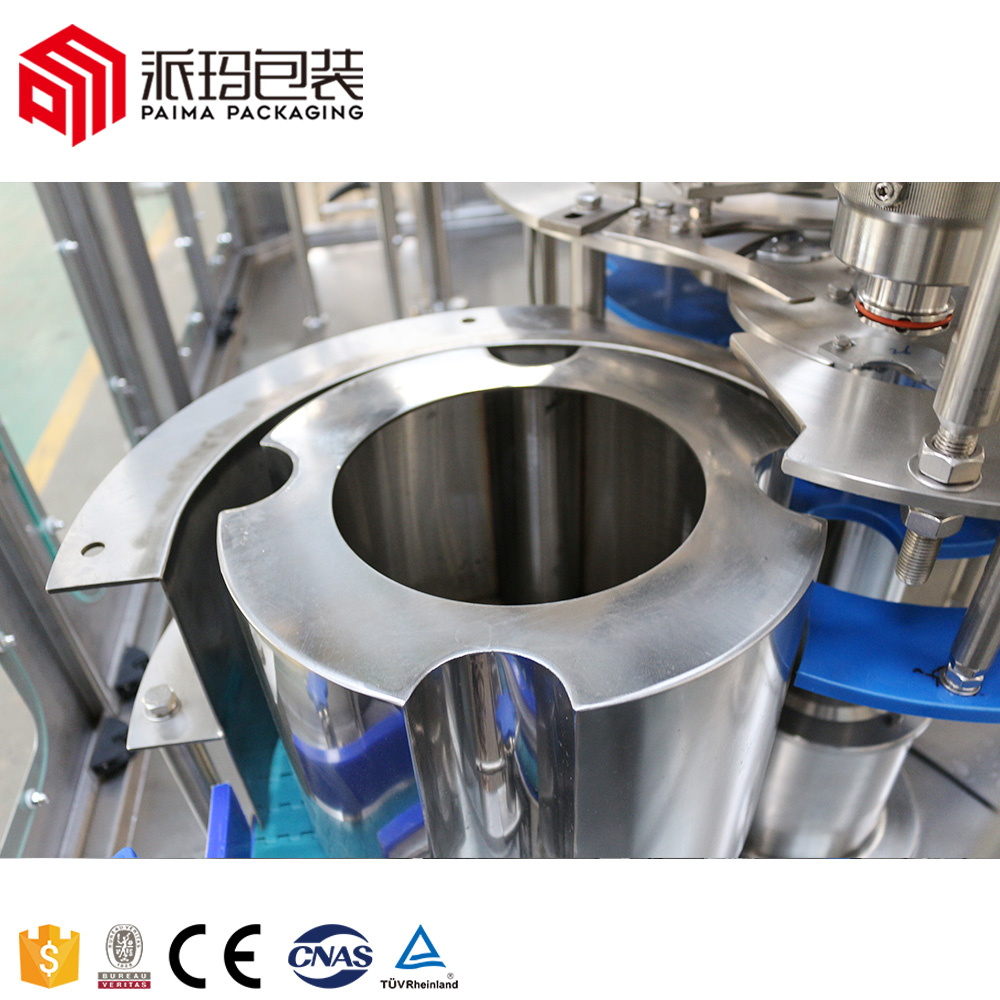

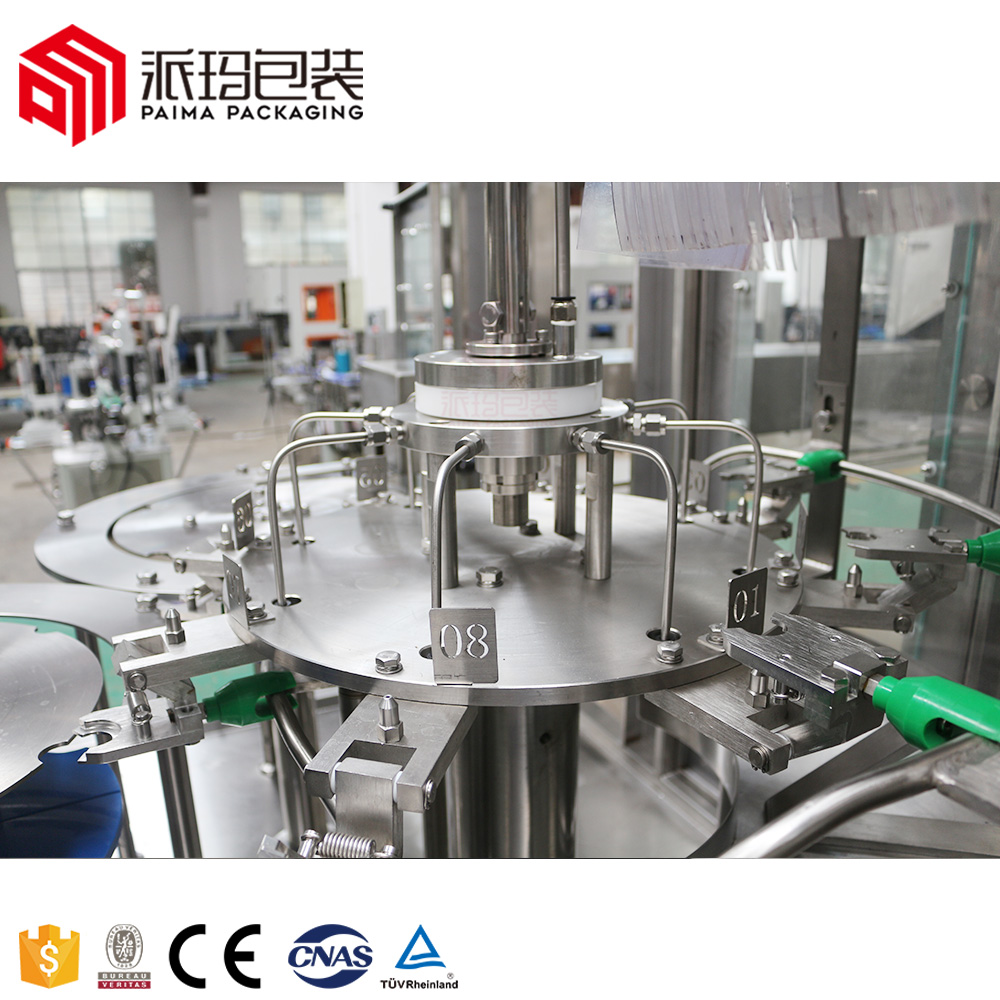

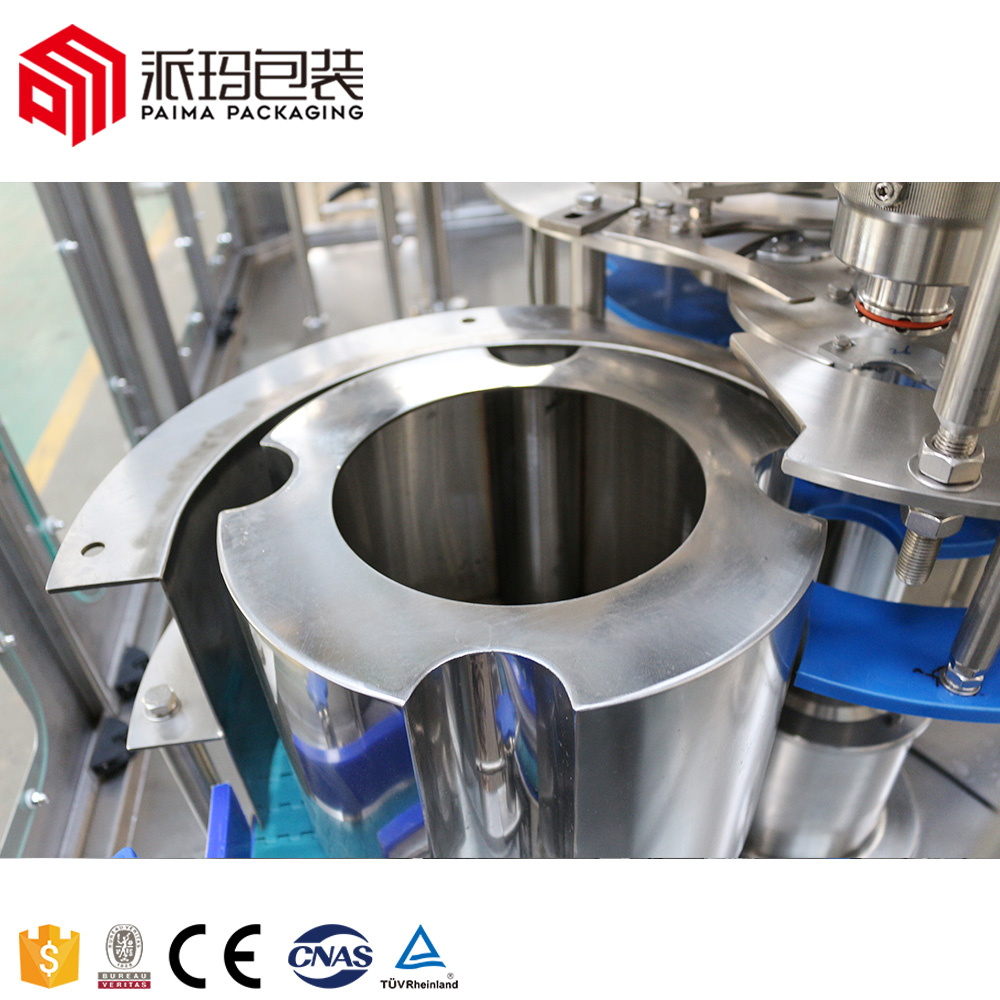

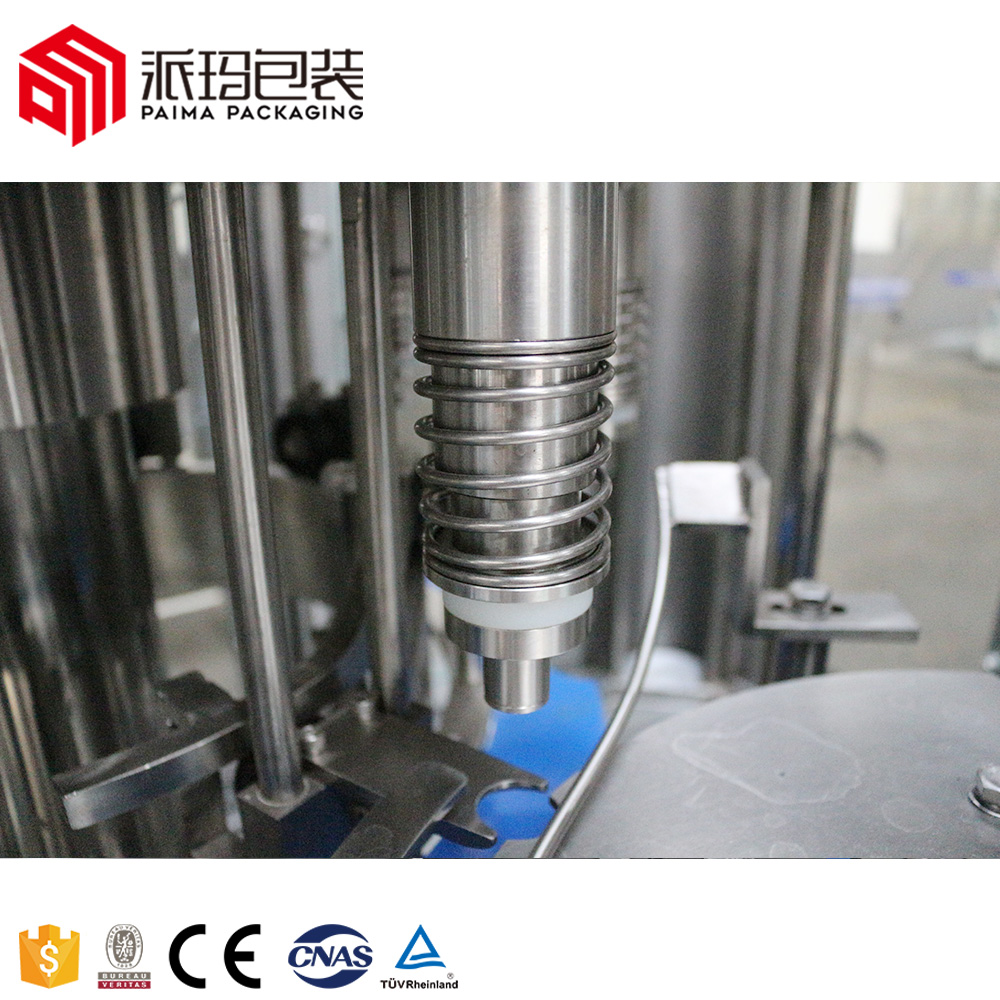

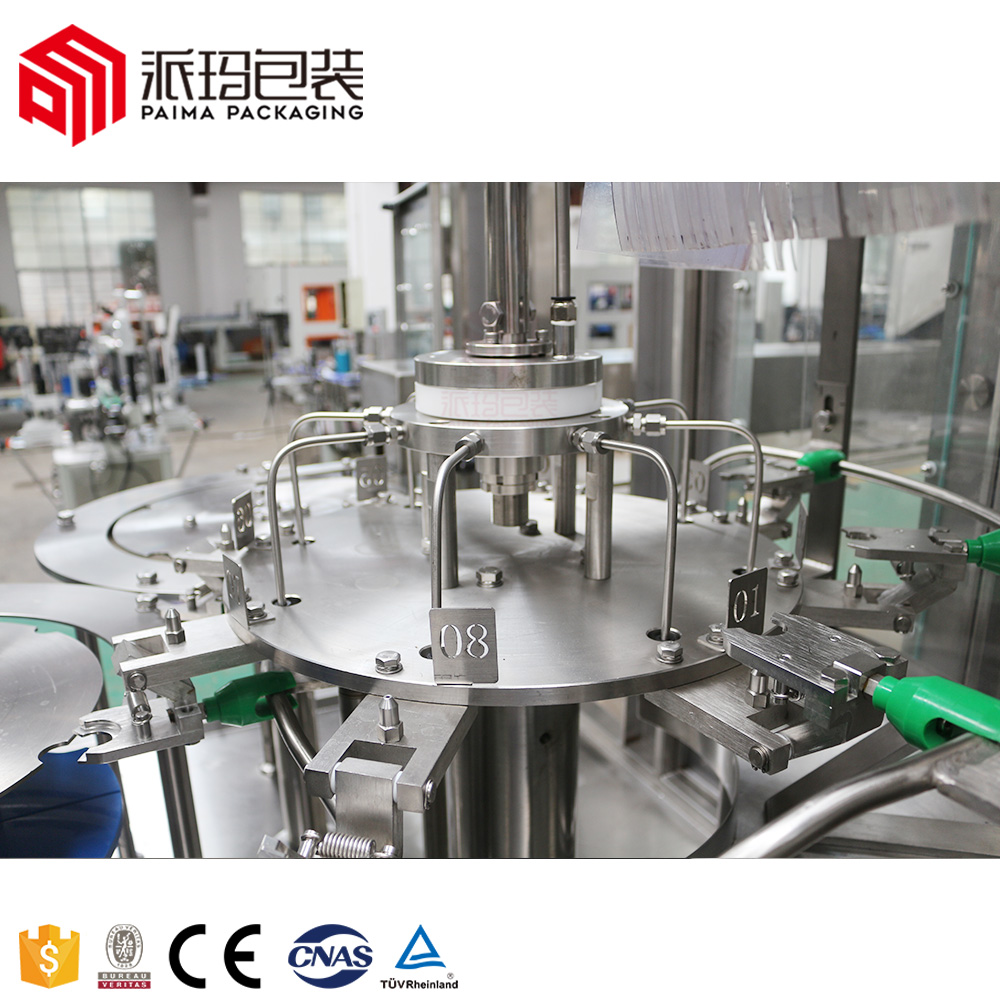

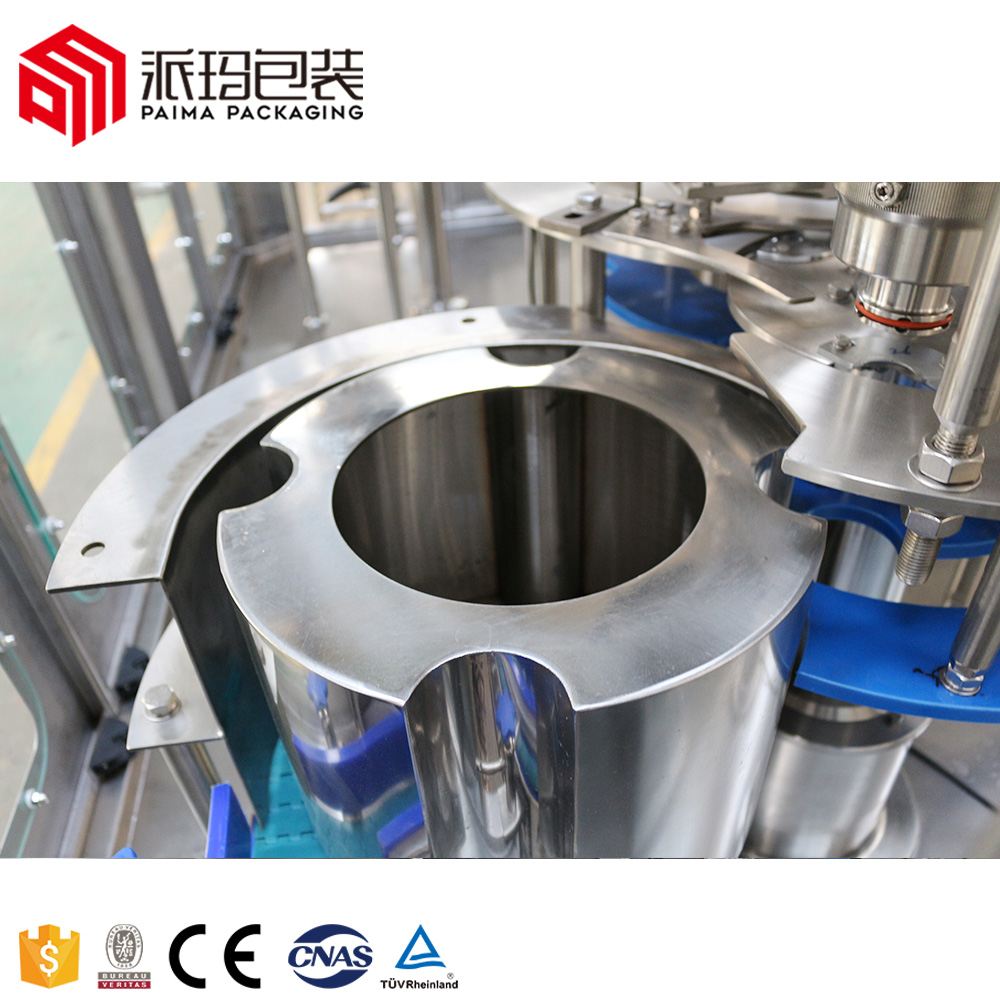

>> Water distributor, bottle clamp, upturn plate, guide rail, protection cover, spraying device

>>All 304 stainless steel rinser heads, water spray style inject design, more save water consumption & more clean

>>304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

>>304 stainless steel washing pumps

>> All food-grade SUS304/316 design

>> Effectively clean bottle and save water

>> Resting waiting for water drops

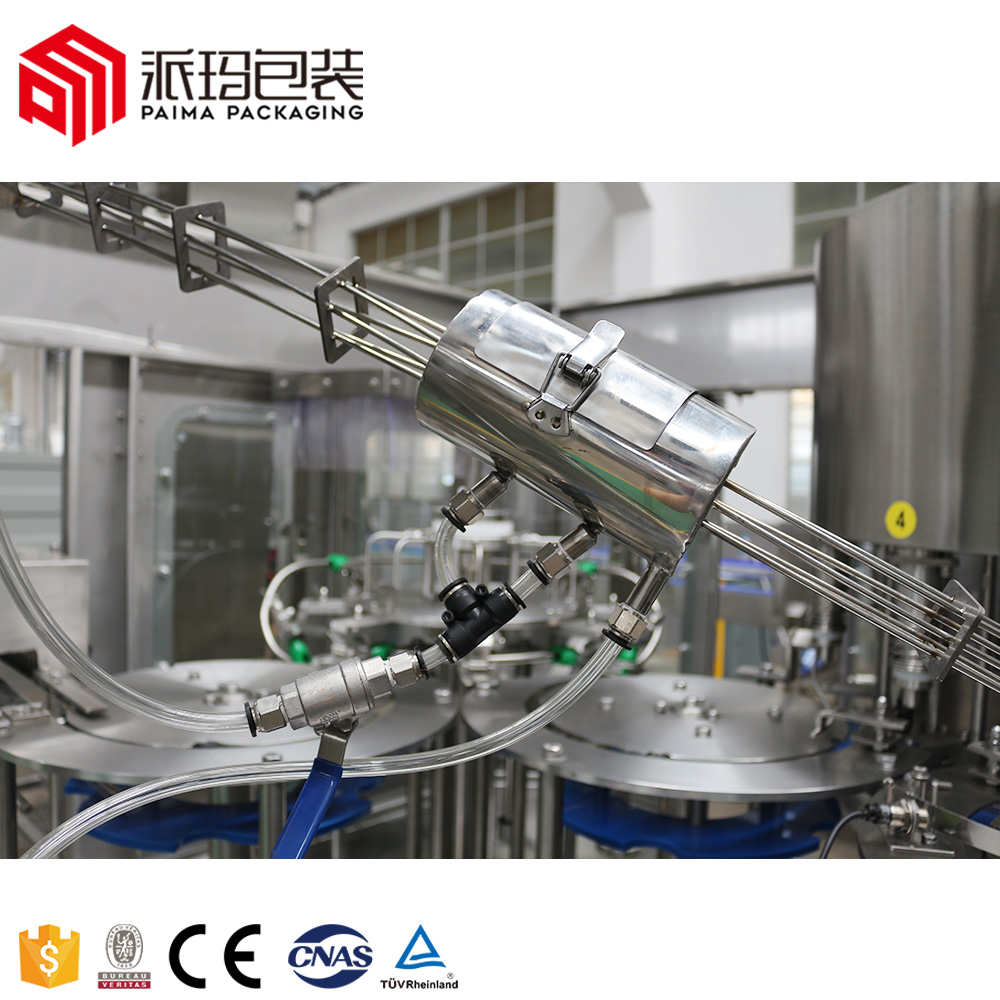

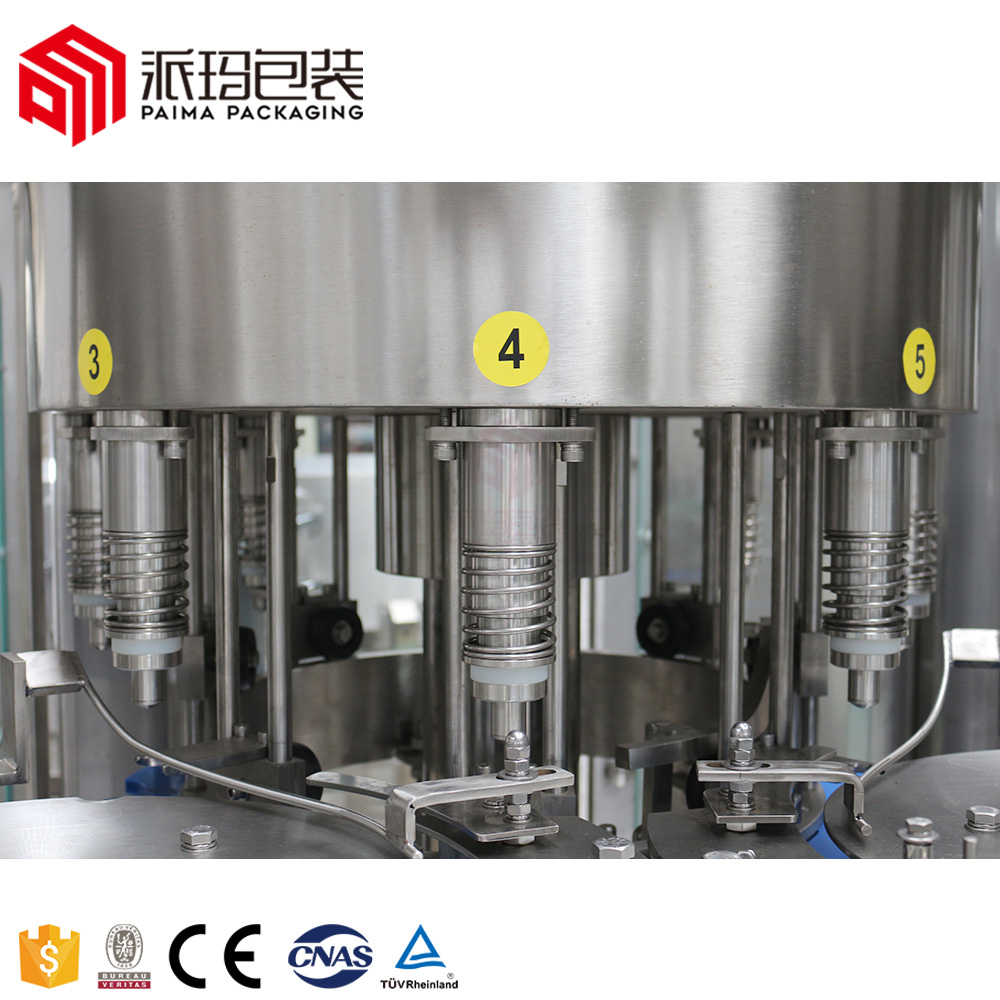

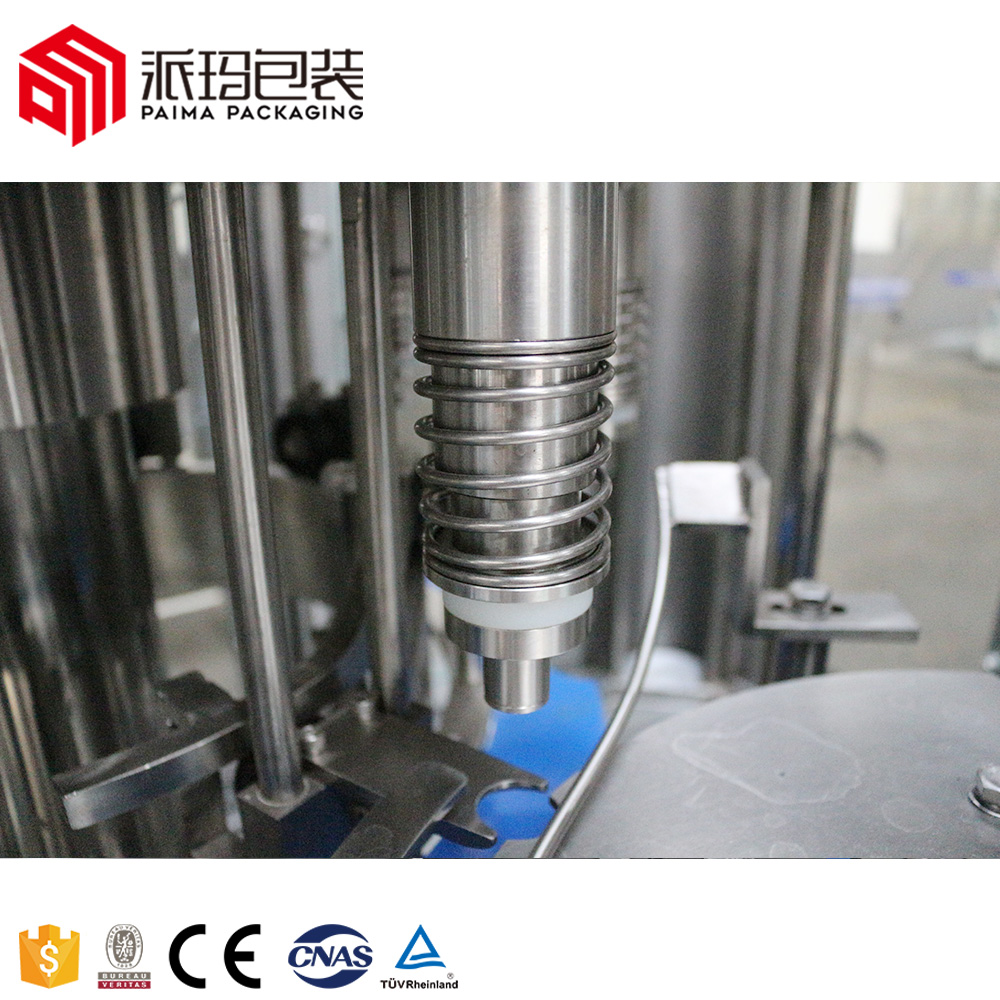

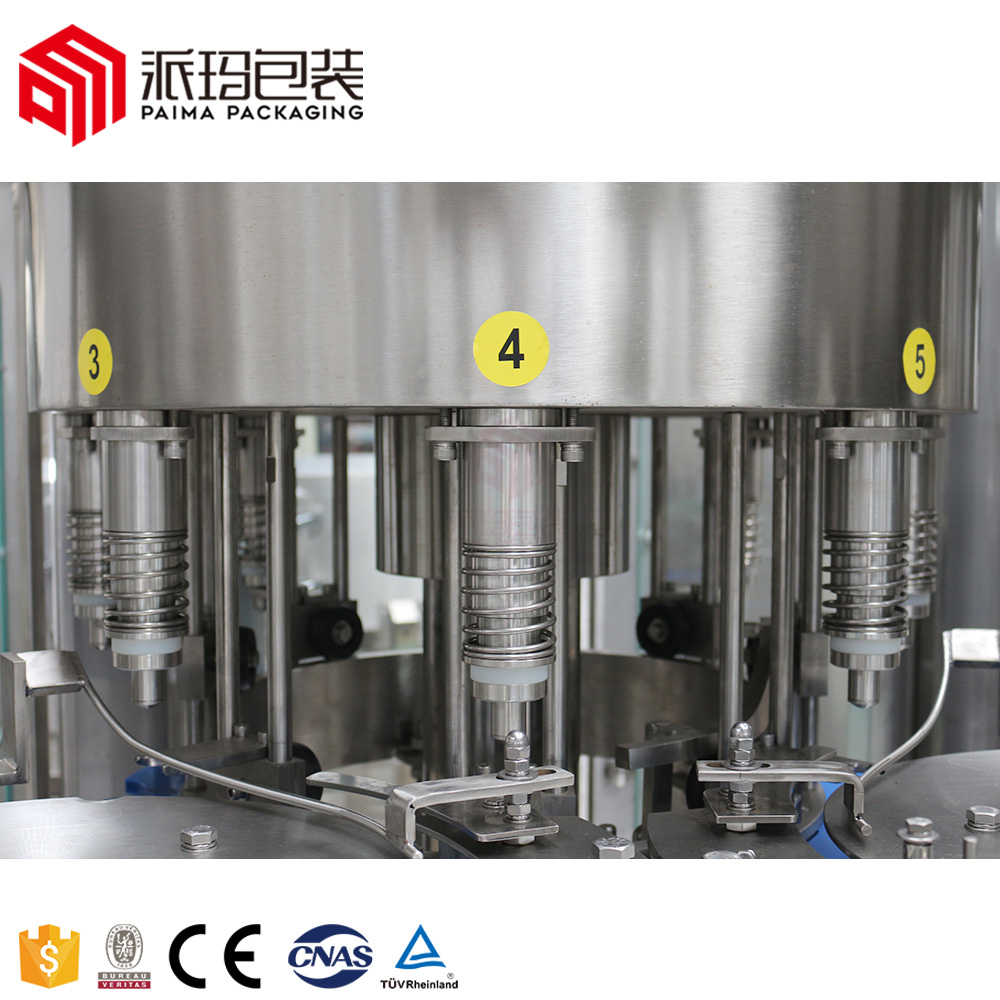

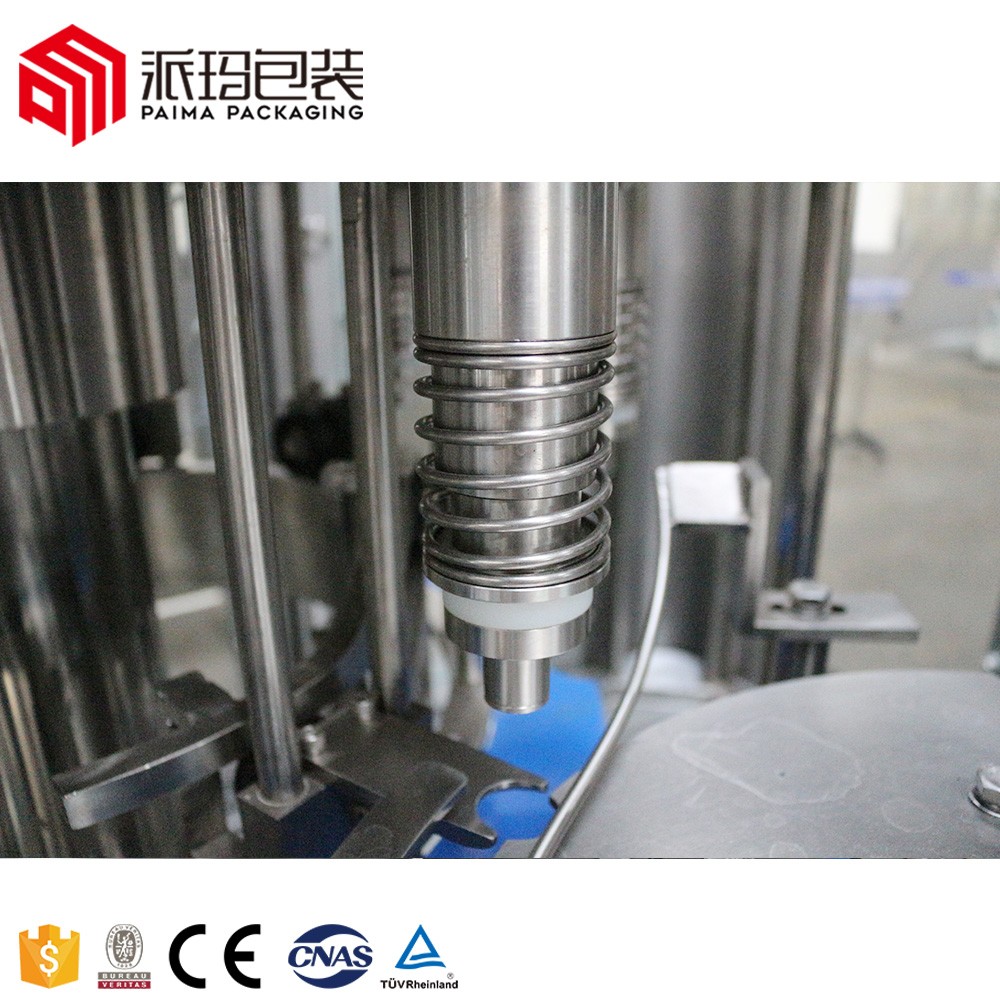

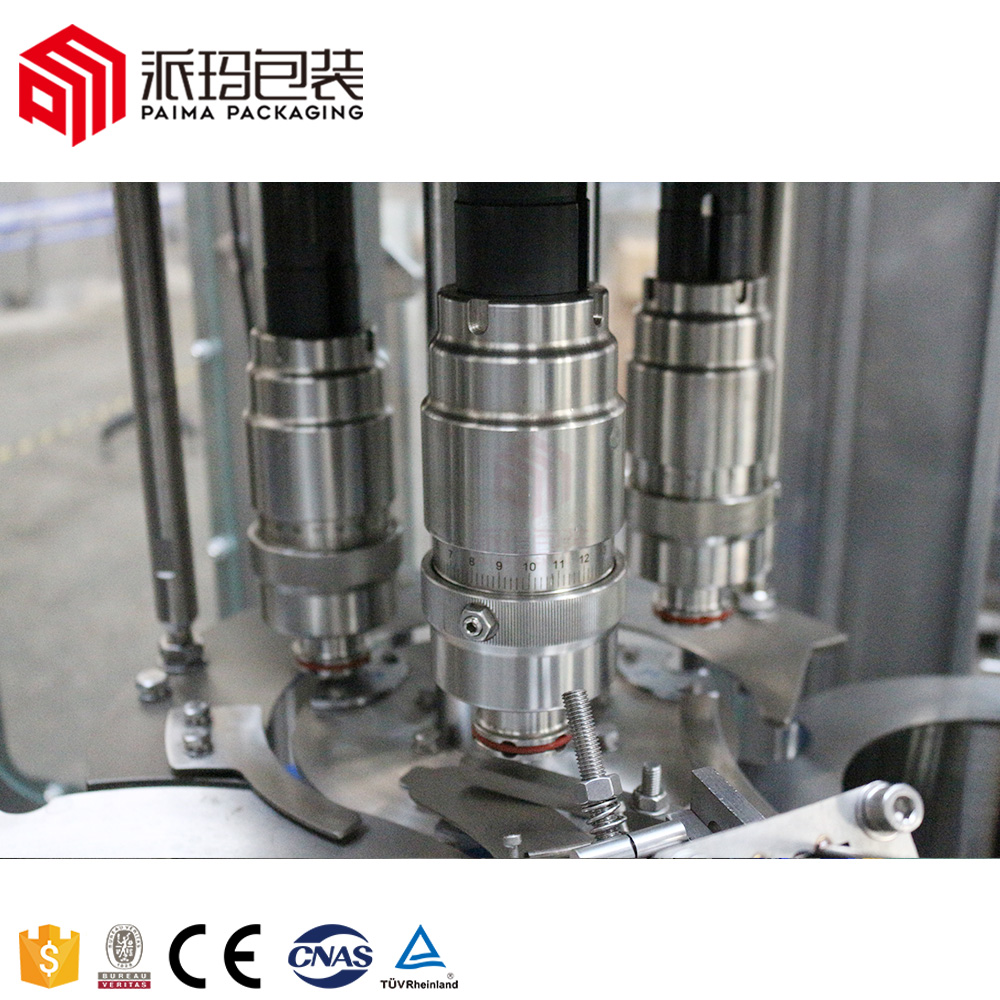

>>High precision filling nozzle, PLC variable signal control, ensure high filling precision & filling smoothly & steadily

>>All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean

>> Filling valve, guide rail, elevating device, etc.

>> Gravity filling method

>> Filling volume adjustable

>> All food grade SUS304/316 design, harmless for beverages and easy to clean

>>No bottle no filling

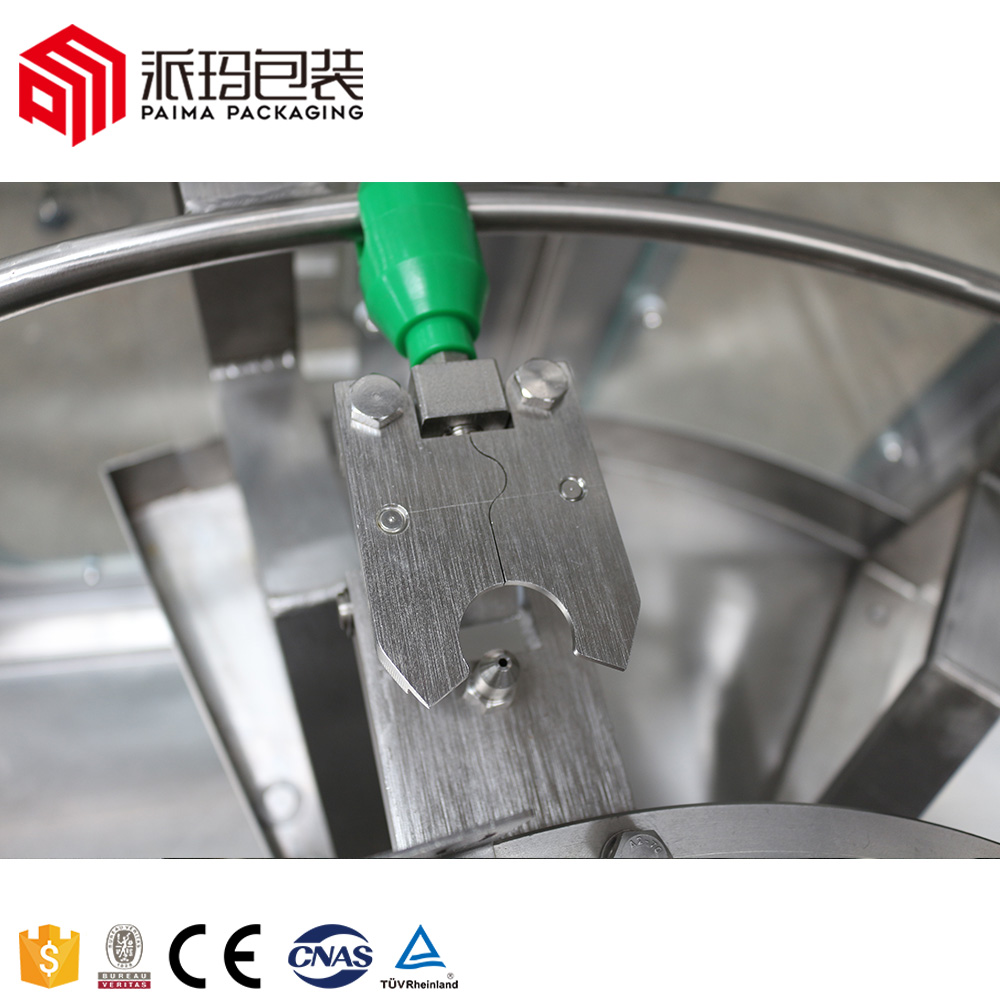

>>Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

>>All 304stainless steel construction

>> Cap unscrambler, cap drop rail, and capper

>> Minimum bottle crash during capping

>> No bottle no capping

The purpose of water treatment is to improve the water quality and make it meet certain water quality standards. Quartz sand filtration, activated carbon filtration, sodium ion softening and other steps can effectively remove turbid organic matter, iron, manganese, and oxides in water, filter suspended solids, colloids, microbial residual oxygen, and some heavy metal ions in water, reduce water hardness, and make various The water quality indicators fully meet the national freshwater drinking water standards.

An automatic bottle blowing machine, which is suitable for blowing various shapes of PET bottles, the capacity is from 100ml to 2000ml. Perform infrared heating, and controllable constant pressure control, in order to achieve the best blowing accuracy. It adopts a programmable PLC controller for automatic control, and the microcomputer touch screen is easy to operate.

This water filling machine is a three-in-one machine that integrates the functions of rinsing, filling, and capping. Drawing on foreign advanced technology, it is designed according to the filling process requirements of mineral water and pure water and is suitable for 200-2000ml plastic bottles.

The control system has many functions such as production speed control, lack of cap detection, automatic shutdown of blocked bottles, and output counting. All controls are operated with advanced touch screens to realize man-machine dialogue operation.

The system is controlled by a Siemens microcomputer, the touch screen directly clicks the menu operation mode, and the parameter adjustment is convenient and intuitive. The capacity is up to 3000bph. By replacing the bottle feeding screw, star wheel, and bottle rack, it can be applied to high-speed labeling of bottles of various specifications. The sensitivity of the label electric eye is adjustable, especially for transparent labels and label backing papers with different light transmittances, which can be distinguished and compared.

1. Anti-high temperature Teflon convey belt, convey steadily, high-strength anti-abrasion.

2. Frequency limitless speed adjust convey belt frame.

3. Convey belt height can make according to client requirement, adjust range: ±50mm

4. Bottle convey machine can meet with client bottle forward direction requirement, can lengthen or shorten.

5. Wing stainless steel heating system, endurance.

6. Meet with product instant stop requirement product-bearing rack device to ensure production line consistency.

want to know more about machines ? contact us now