want to know more about machines ? contact us now

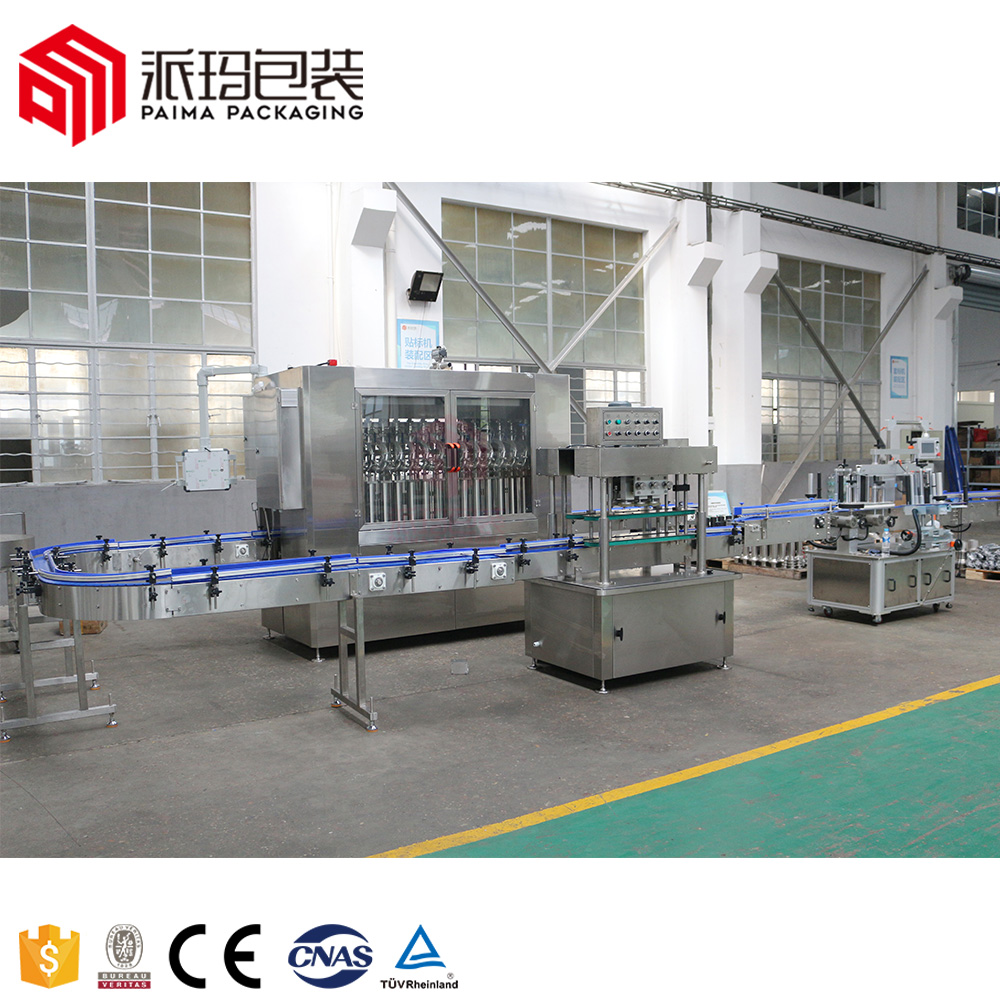

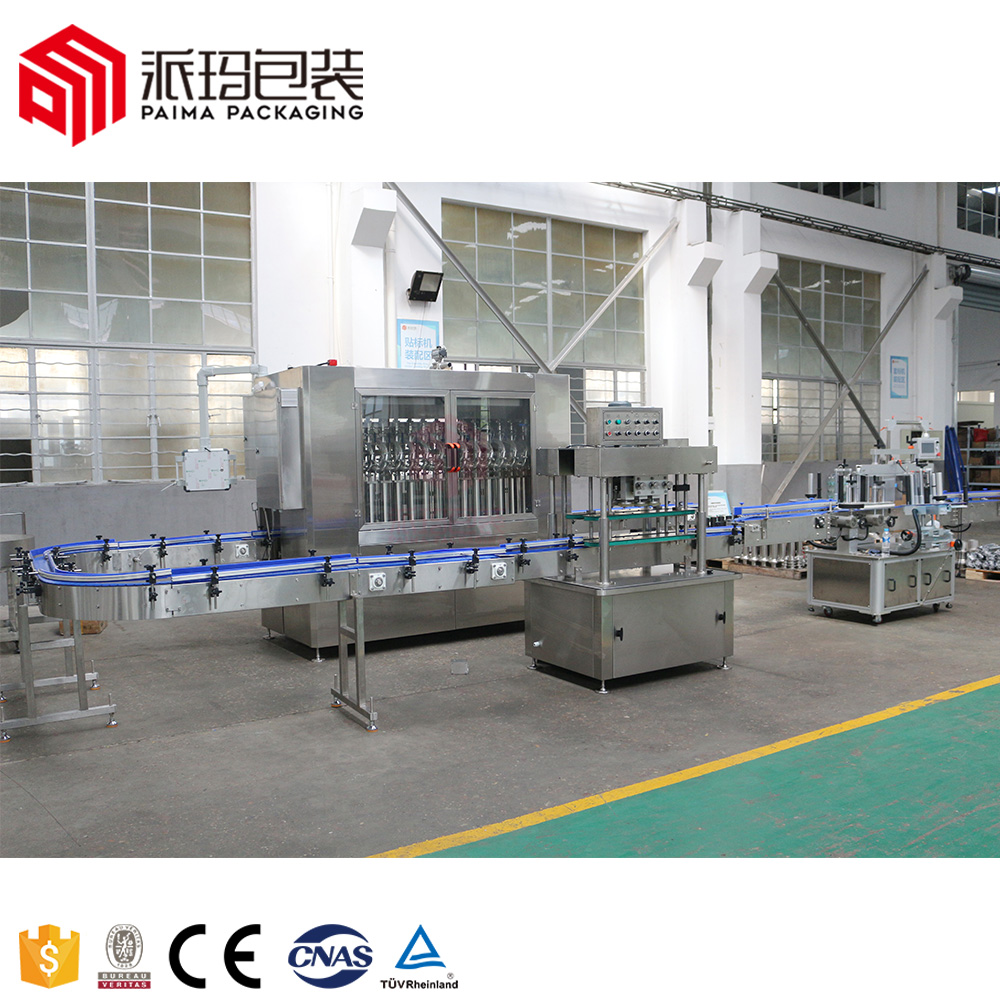

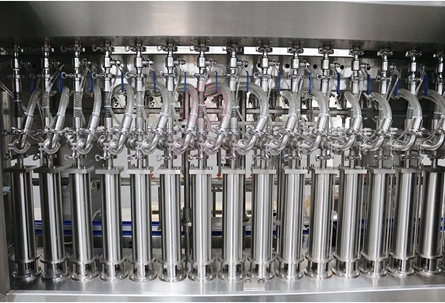

This type of machine is suitable for filling viscous, inviscid, and corrosive liquid. It's widely applied in plant oil, chemical liquid, and the daily chemical industry. It adopts linear type filling,electromechanical&instrucmental integration controlling. It's simple and rapid for changing the varieties with unique design and superior capability. Its appearance accords with the international machinery concept.

This type of machine is suitable for filling viscous, inviscid, and corrosive liquid. It's widely applied in plant oil, chemical liquid, and the daily chemical industry. It adopts linear type filling,electromechanical&instrucmental integration controlling. It's simple and rapid for changing the varieties with unique design and superior capability. Its appearance accords with the international machinery concept.

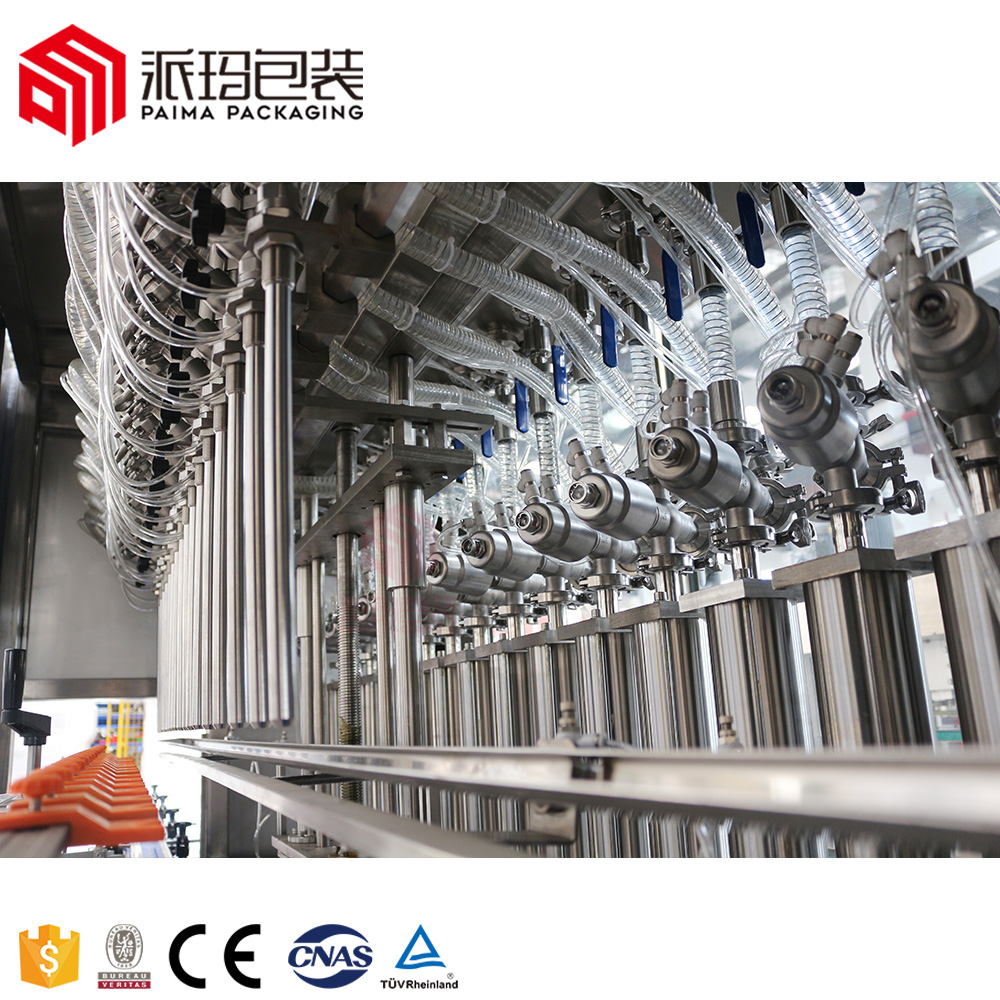

Germany SIEMENS PLC and touch screen control make it an intelligent protection function. Vacuum anti-dropping device ensures no leaking situation in production. Electronic adjusting for volume system, frequency control, and photoelectric detecting system(Germany TURCK brand) are applied in this machine.

|  |

1. The weighing instrument is a dedicated controller for quantitative packaging scales, with fast response, high precision, and complete functions.

2. The load cell is a Toledo intrinsically safe sensor, which is sealed with multi-layer media and has strong anti-eccentric load capability. It has the characteristics of dustproof, waterproof, explosion-proof, button resistance, and corrosion resistance, and meets the IP67 sealing standard.

3. The flow of materials is controlled by the double-speed ball valve and the bottom valve of the spray gun, which is accurate and reliable. The user can adjust the filling speed through the instrument keyboard.

4. This machine adopts a programmable controller (PLC), touch screen operation control, easy to use and adjust.

5. Adopting unique software and hardware design, which can effectively prevent material from dripping and leakage, and ensure the cleanliness of filling equipment and packaging containers.

6. Each filling head has a weighing and feedback system, which can set and micro-adjust the filling volume of each head.

7. The filling method is submersible, which can effectively reduce the generation of foam and meet the filling of materials with different characteristics.

8. Adopting advanced sensing elements to achieve no barrels and no filling. When the barrels are blocked, the host will

automatically stop and give an alarm.

1. Bottle making system

pet preform→Autoloader→reheater →molding→ bottles

2. Bottle filling system

Full automatic oil Filling machine→Capping machines

3. Packing system

Full-automatic labeling machine →Inkjet machine →Full automatic PE film packing machine / Carton packing machine→ Warehouse

| Oil Bottle Filling Machine Bottle Material: PET Bottle Cap: Screw cap, thread aluminum cap, rolled aluminum cap. Bottle Volume: 1-5L Production Speed: 960-2880BPH |

| |

|  |

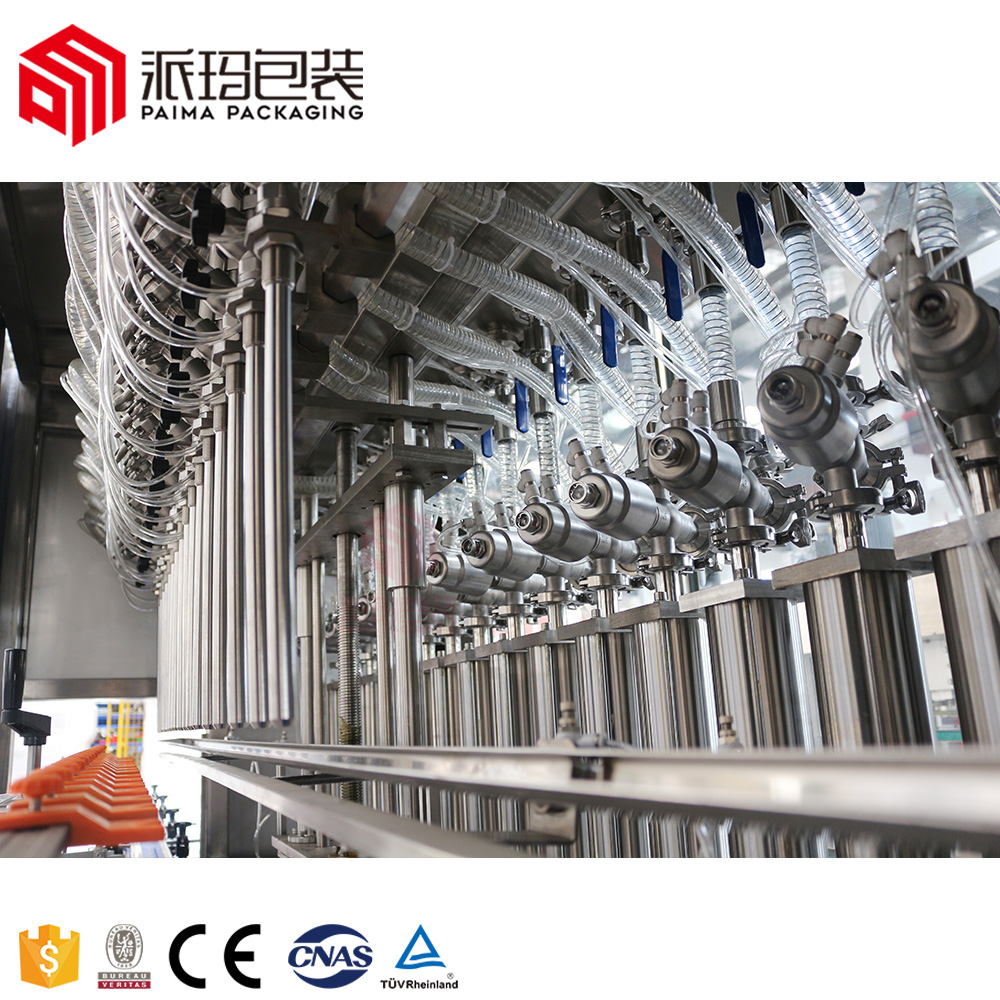

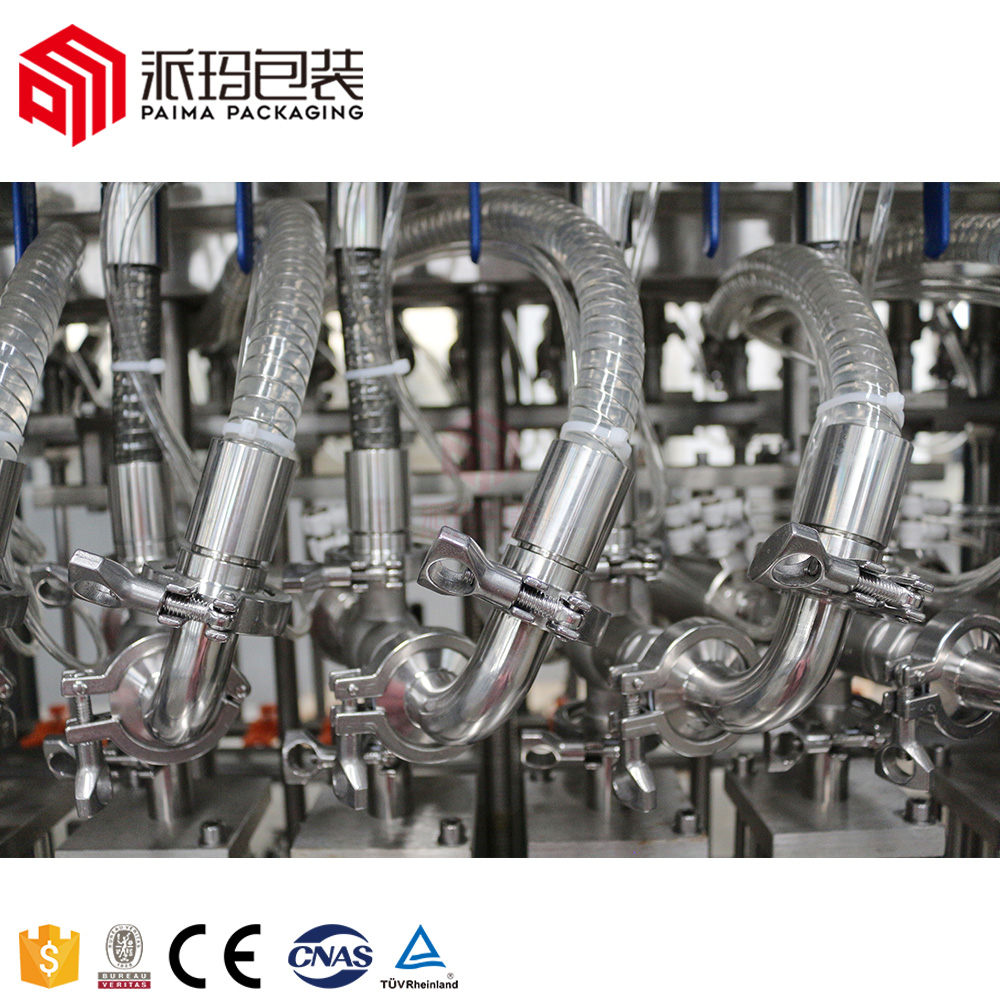

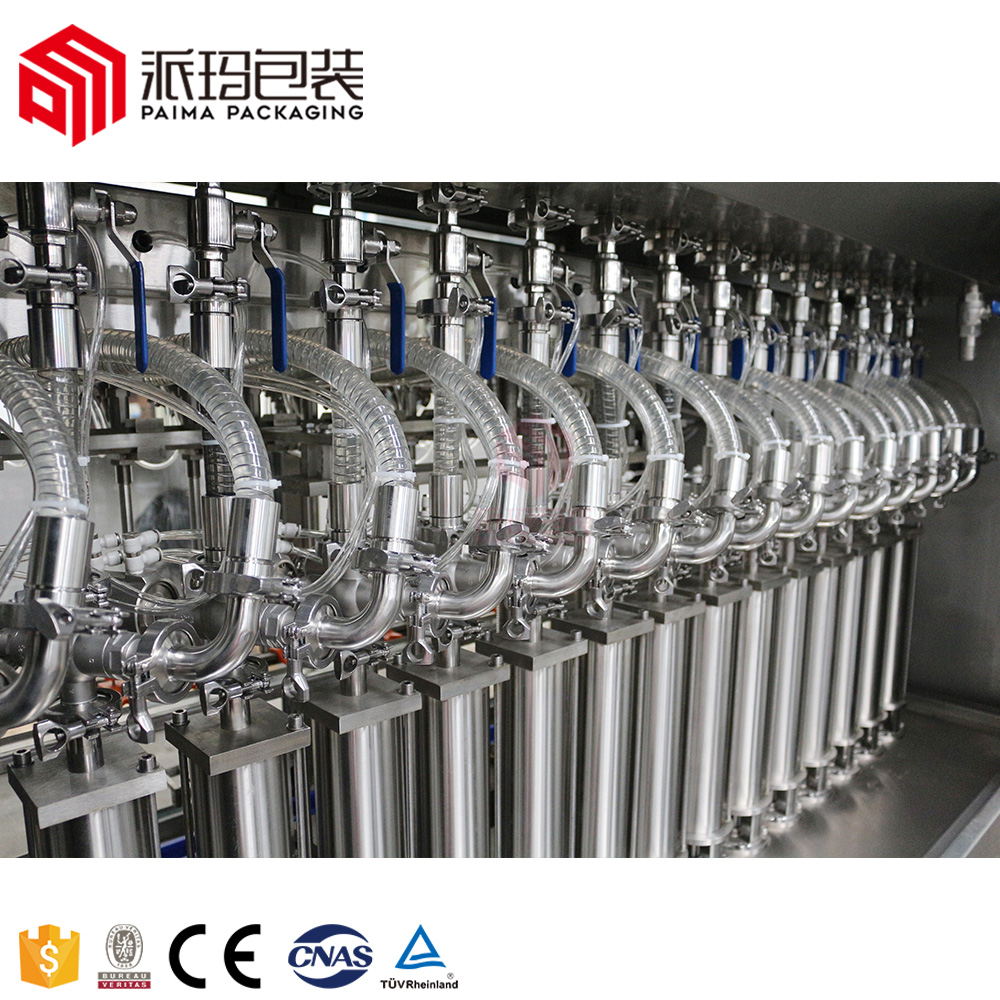

According to the customer's different choice, can be equipped with different materials of pipe, to meet the customer variety of different liquid safe filling.

1. Teflon corrugated pipes

This pipe is suitable for edible oil, lube oil, liquid detergent, liquid soap, hand sanitizer, etc. It is suitable for various viscosity

and non- viscosity liquid.

2. Food-grade silicone hoses

This pipe is suitable for Mustard sauce, mayonnaise, chili sauce, ketchup, and other sauce materials, etc. Filling with non-residue.

3. Food grade rubber hoses

This pipe is suitable for edible oil, Ketchup, hot sauce, etc. it will be strong enough and will not pollute the food material.

| |

|  |

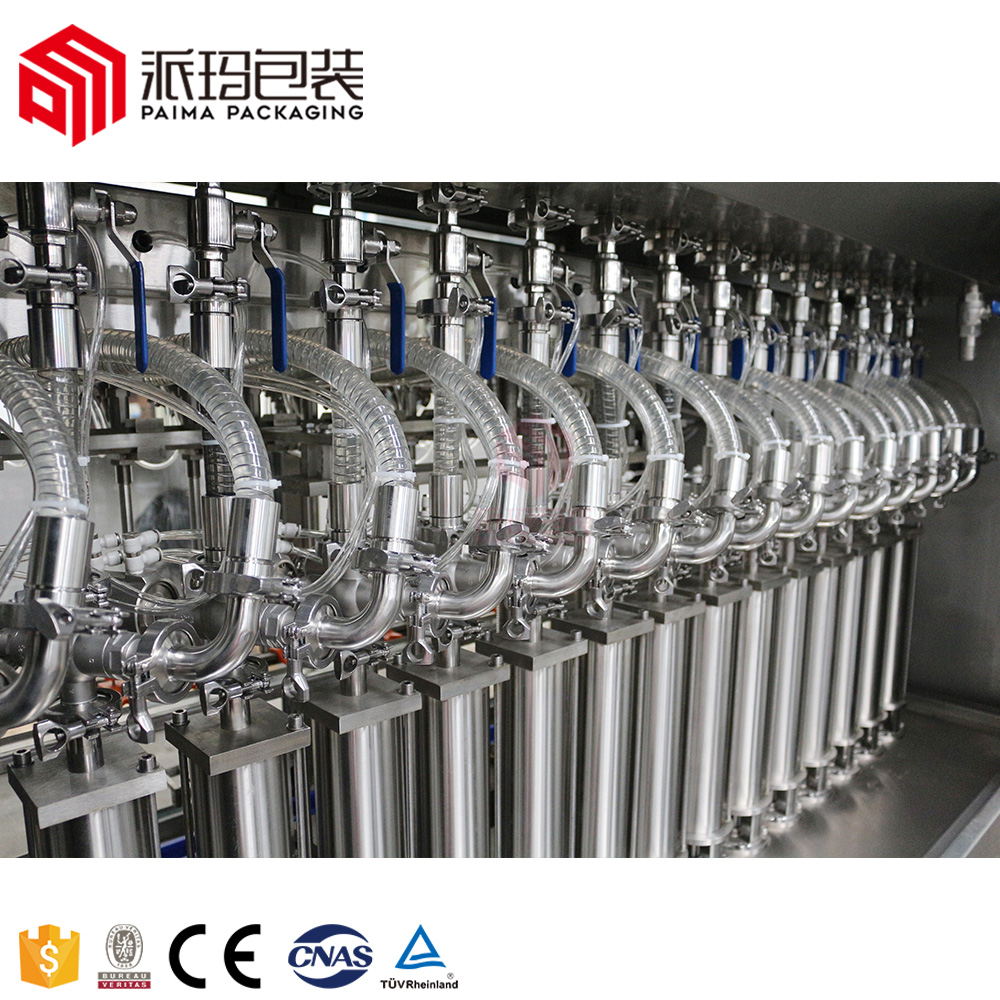

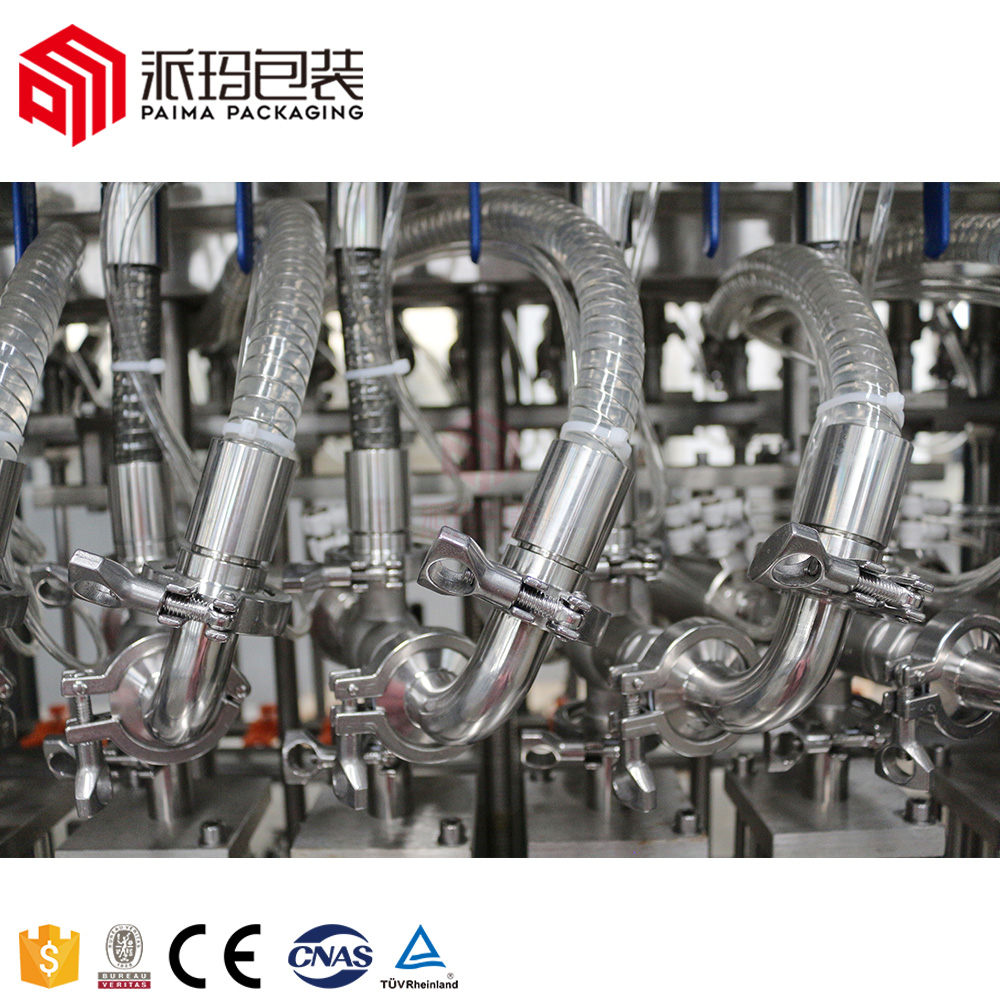

1. According to different filling materials, we will use different qualities of piston rings.

2. White is usually used in filling edible oil products, the black one is usually used in industrial oil.

3. Both these two kinds of piston rings are made of Teflon material,inside the rings is a spring,it has the function of automatically adjust the gap caused by friction. So that the piston rings have a long service time.

| ||

|  |  |

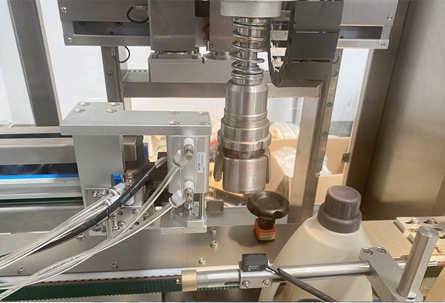

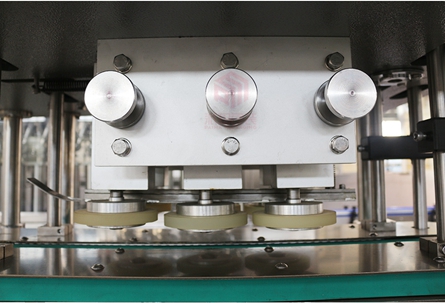

This machine applies and torques caps into containers. It's suitable for various materials and figure containers. Such as plastic bottles, glass bottles, and metal bottles. If we want to change different materials or figure bottles and caps for tightening, we do not need to change any components. We just adjust the position of several components. No bottle no cap falling. Cap unscrambler machine, conveyor, cap screw parts, bottle clamping strap can be conversion adjusted to meet the tightening requirements for various bottles and caps. The machine is made of good type stainless steel, also applied to GMP standard requirements. (custom-tailoring diversified for special specification )

1. There is no need to replace the parts when changing the bottle shape, just adjust the position of some parts. The machine is simple in structure and easy to adjust.

2. When use pressure capping type, this machine can be changed into a pressure capping type machine.

| ||

|  |  |

The machine adopts linear bottle feeding, PLC program control, double cylinder bottle positioning, can clear up and drop the cap automatically. Single-head machine in the double-action lifting cylinder to grasp the cover firstly, then screw cap. The screw cap adopts the air expansion type catch cap and is equipped with torque control, the screw cap will not damage the bottle cap, the machine is suitable for the screw cap of the barrel with a large diameter.

1. Servo Motor Capping

Servo motor is used to control the torque of the rotary capping head, It won't damage the bottle and the caps. The action of grasping the cap is completed by the air cylinder.

2. Easy Adjustment

The capping head can be disassembled independent, when changing the capsize, you can change the capping head to fix new productions

3. Linear Cap Unscrambler

Linear cap unscrambler machine for cap sorting, Belt type conveyor for the caps, the speed and stability of cap conveyor are increased, and won't occur caps missing.

| ||

|  |  |

Automatic double-side labeling machine for square bottles or flat shape of things off the side of the bottle labels, which can be applied in many industries for automatic labeling and another irregular shape of the bottles.

Easy operation

Adopt mature PLC control technology, make the machine stable and high-speed. Can be suitable or square flat bottles at the same time.Adopt touch screen control system, simple, practical and efficient operation

Easy Adjustment

Adopt a high-quality sponge wheel to leave some space between the bottles, so as to ensure that the labels will not be missed. The rotary speed of the sponge wheel can be adjusted to adjust the space between the two bottles.

Widely Use

The parts of the machine that store labels and collect label paper are designed to be adjustable to accommodate a wide variety of labels.

Special Customization

We can make the labeling machine can suitable for the square bottles, flat bottles, and round bottles at the same time. When changing the bottle from square or flat to round bottles, it only needs a simple adjustment on this machine.

High Accuracy

Adopt photoelectric equipment imported from Germany, and a high-quality servo motor, the labeling accuracy is greatly improved.

Pick & Place Case Packer adopts PLC + touch screen control, equipped with bottle alarm stop and no bottle no packing safety device. The operation interface is simple and convenient. Suitable for all types of bottles products, such as PET bottles, PP bottles, all kinds of plastic bottles, glass bottles, special-shaped bottles, cans, aluminum cans, and so on, Pick & Place Case Packer is widely used in the food, water, medicine, chemistry industries.

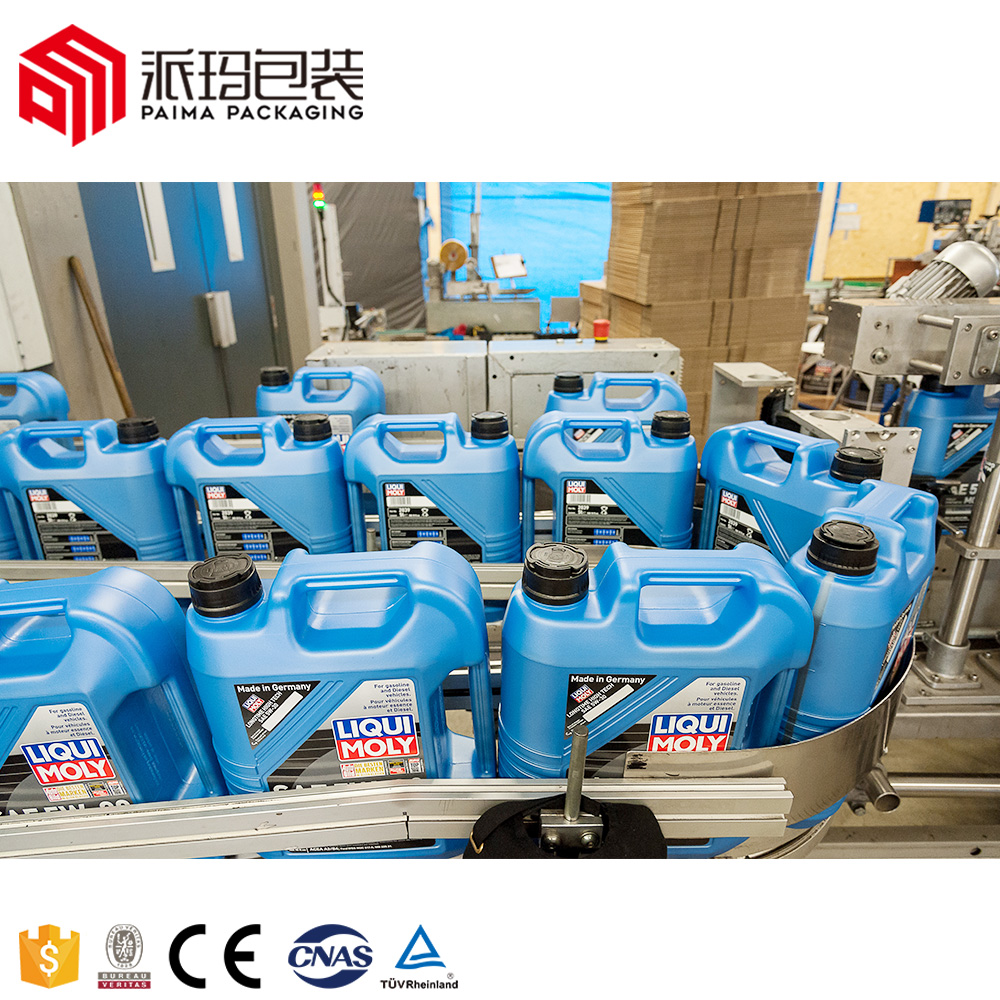

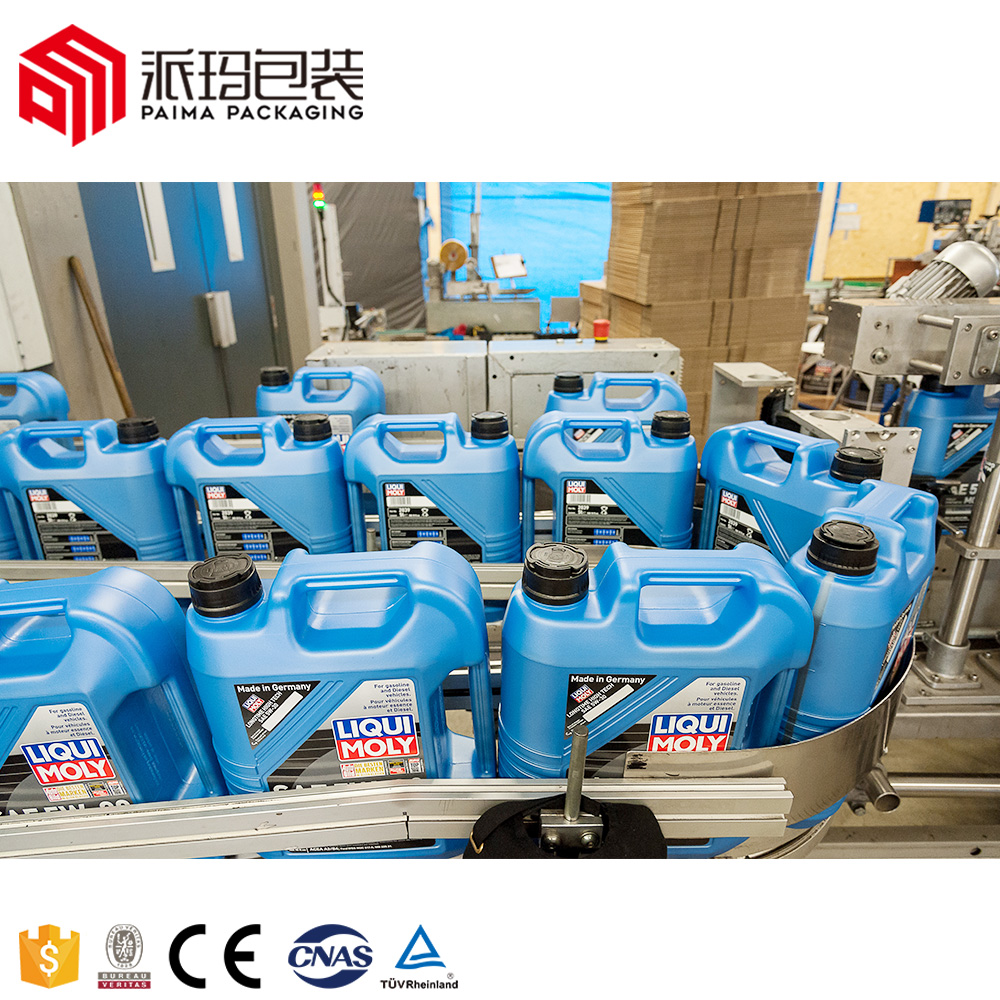

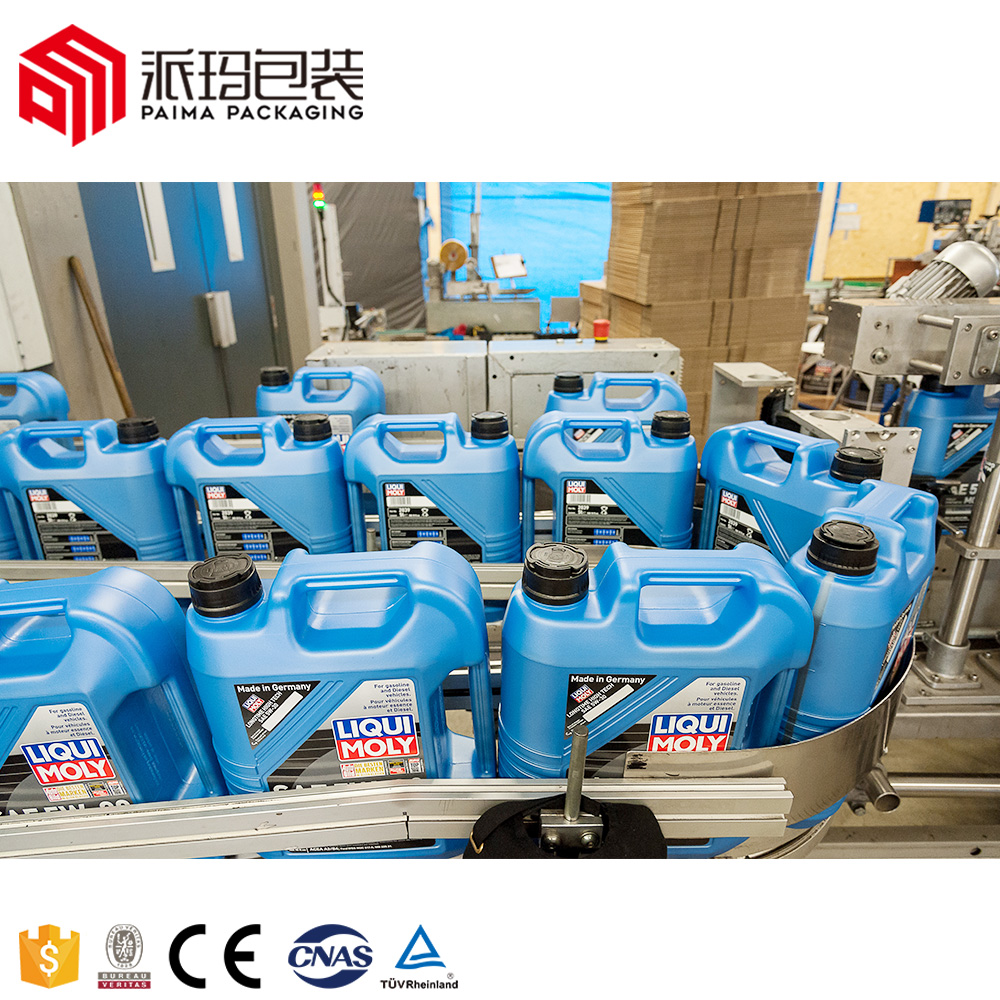

Customer Cases

For nearly 12 years, Paima Packaging has provided bottling & packing equipment of liquid solutions to companies all over the world, water bottling lines, juice filling lines, carbonated soft drinks turnkey projects, oil and soda water bottling line, and labeling and packing machinery. Paima PacKaging offers complete filling and packaging solutions for the beverage industry and excellent lifelong time service.

We have a customer from Ethiopia who ordered a complete water line from water treatment to the back-end packaging equipment. And last year, when we went to Ethiopia to participate in the exhibition, we especially visited them. These are the real pictures we took from our customer's factory.

| ||

|  |  |

Our cooperation partner

Packing and Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient, and efficient packaging services will be provided.

| ||

|  |  |

ABOUT PAIMA:

Paima Packaging is a professional manufacturer that consists of research&design, production, and marketing in one unit, It is a professional manufacturer of beverage filling and packaging production line and packing material Since the establishment, we Rely on the ideal " faith and Steadfast, pursue remarkably" we insist on the realistic policy and show the perfect service to our customer, we always design and update our machine quality based on the ended user's actual use situation, due to our hard-working, we help our customer save a lot of labor cost and enhance their market competitiveness.

Due to the advanced technology, the fine processing equipment, we are already popular and reliable to our customers with its machine quality and faith, we welcome the customer from all around the world visit our company, thank you for your trust and help honestly, we believe mutual cooperate and respect mutual benefit and treat the person faithfully, in the end, we will succeed together.

FAQ:

1. HOW TO FIND US ?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufacturers and not traders

● Visit the exhibition in different countries

● Send us a request and tell us your basic inquiry

● Our sales manager will reply to you in a short time and add an instant chatting tool

2. YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fulfill your request and you interested in our products, you may pay a visit to Paima Machine site

● The meaning of visiting supplier, because seeing is believing, Paima Machine with own manufacture and developed& research team, we can send you engineers and make sure your after-sales service.

3. HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on-time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facticity of our bank account.

4. HOW TO ENSURE THE QUALITY ?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure stable running in the customers' factory

5. THE AFTER-SALE SERVICE OF PAIMA MACHINE ?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to the customers' factory to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customer's project.

want to know more about machines ? contact us now