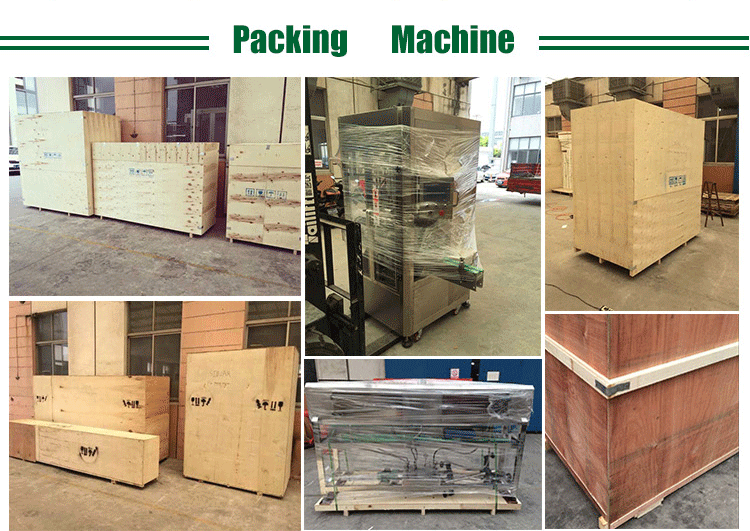

want to know more about machines ? contact us now

Production capacity: 9000BPH; Power supply: 3P 380V 50Hz; Applicable label: OPP label; For different bottles, we need to make moulds.

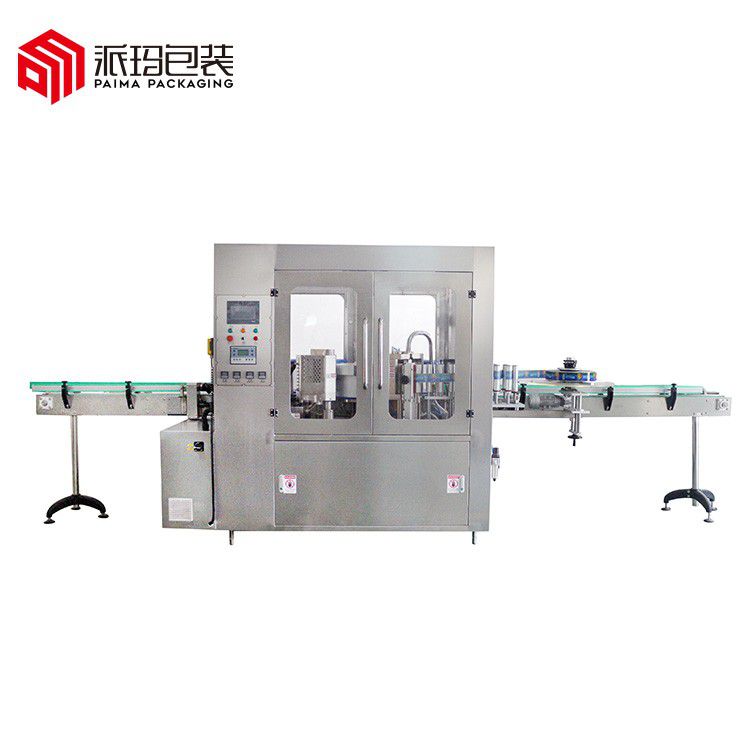

Liner type hot melt opp labeling machine

DescripFeatures:

|

1 Adopt wheel labeling way; |

|

2 Label transmit via label wheel, run along the guide rail and operate the labeling work; |

|

3 When the label through the appointed wheel, the sensor will automatically detect I-Mark; |

|

4 Once confirm the electronic eye position, the demodulator will automatically adjustment the speed of wheel, and then appoint the label cutting position accurately. |

|

5 The label through the wheels and then enter into the cutting part to carry out the label cutting work, the label cutted will be send to the vacuum-grip cylinder. |

|

6 The containers which is transmited by conveyor belt will be arranged properly via star wheel, then, the label which has been painted with glue will proceed the first labeling in the roller area, last, rely on the synchronous belt to proceed the last labeling operation. |

Parameter:

|

No. |

Item |

Parameter data |

|

1 |

Voltage |

380V |

|

2 |

Frequency |

50Hz |

|

3 |

Power |

8KW |

|

4 |

Available bottle dimension |

Diameter:40-105mm, height=80-350MM |

|

5 |

Label specification |

Length:125-325mm,Height:20-150mm |

|

6 |

Gluing way |

Roll painting (about 10mm, both label head and tail) |

|

7 |

Capacity |

9,000 bottles per hour (500ml bottle) |

|

8 |

Glue Consumption |

l kg/ 100,000bolttle(label height:50mm) |

|

9 |

Compressed Air Pressure |

MIN5.0bar MAX8.0bar |

|

10 |

Consumption of Compressed Air |

0.2M³/minute |

|

11 |

Total Weight |

2500Kg |

|

12 |

Overall dimension |

L=3150,W=1770,H=1800 |

Machine detail picture

|

|

|

|

|

|

want to know more about machines ? contact us now