Before performing any maintenance operation, fixing or cleaning of the machine, position the right selector in position '0' and make sure the electrical power supply has been removed from the machine.

Before we get started, let us take a look at the features of the machine.

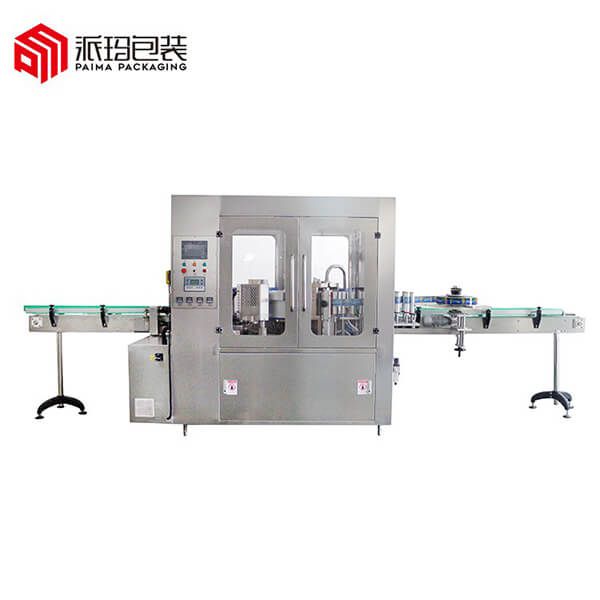

General description of the machine:

The automatic labeling machine is designed for the application of self-adhesive labels for reels on bottles, jars, and cylindrical cans. The machine can be supplied with accessories for the application of labels on square or rectangular bottles. The machine may also be equipped with an ink date imprinting system.

If you want your labeling machine to work for as long as possible, it is important that it be well maintained. Here we are going to give you some keys to clean your labeler from time to time and avoid headaches in the future.

If at any time you notice that your labeler works irregularly or you think that it has something stuck, most likely, you will have to clean it to make it work normally again.

Clean the labeler on the outside

To clean the cover of your labeler, do not pour the water directly over it or you could cause an irreversible problem.

You should use a damp but not wet cloth so that no drops fall.

Clean the automatic hot melt glue labeling machine carefully, using a clean cloth soaked in water mixed with a non-aggressive detergent.

Remove any glue and label residue that may have been left on the gummed rollers.

If you want to clean compartments you can use a cotton.

Clean the head

If you want the print to look sharp and clear, you need to periodically review the print head.

Sometimes the labeler or label maker will include a small tool to clean the thermal print head.

It is a small stick with a sponge. To clean the head you will have to carefully remove the label cartridge and pass the stick gently. If you don't have the cleaning tool you can pass a stick or a thin piece of cloth with the help of a stick.

The idea is to remove all possible dust or debris from the holes in the head.

Clean the cutter

The cutter blade may also have debris that affects the label when it is cut. So it is also important to clean it if possible with a swab dipped in alcohol.

You should be careful because the blade is sharp and you can easily cut yourself.

Clean the sensors

Be sure to clean the sensors when you are reviewing your labeling machine. Take special care in this part. Do not exert force or too much pressure.

We only seek to remove dust or small debris that may have accumulated, but there should not be many. Gently wiping the stick or rag will suffice.

Finally, each model has a specific instruction manual, which will make things much easier with specific instructions for cleaning and maintenance of the model we have purchased.