want to know more about machines ? contact us now

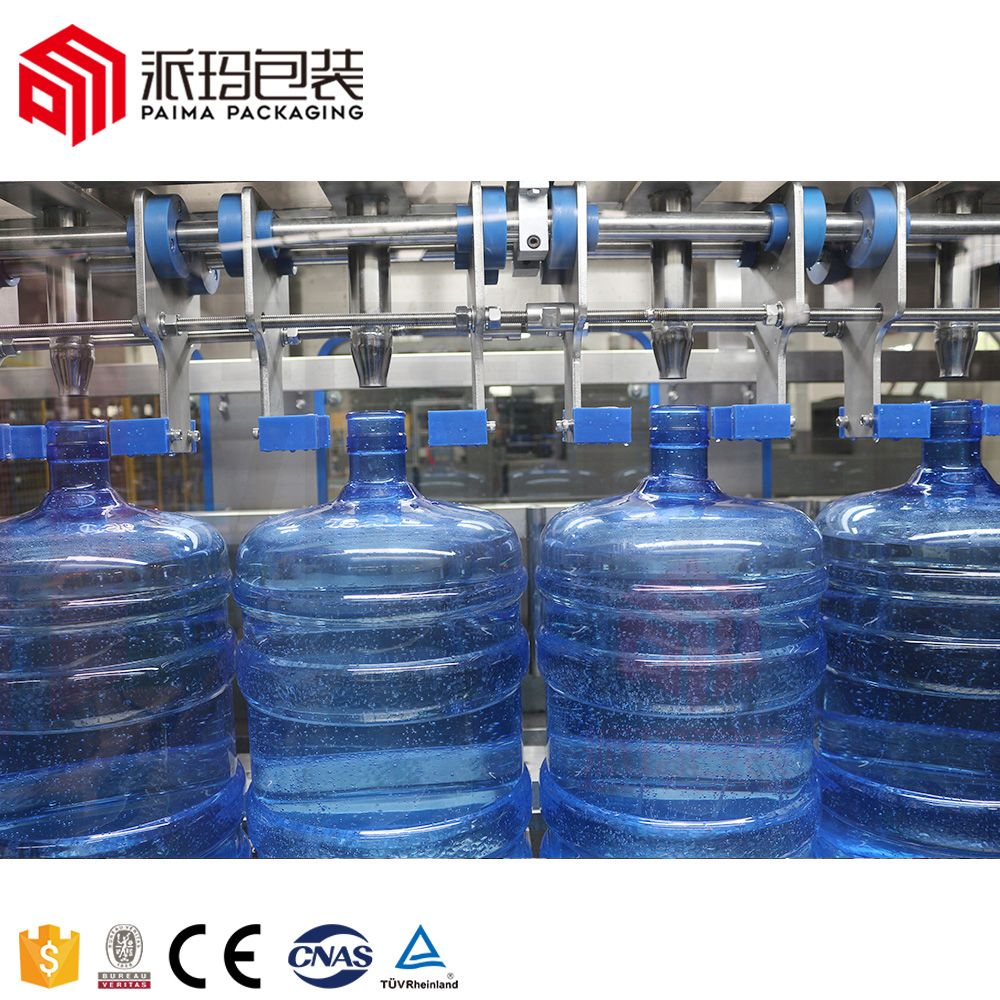

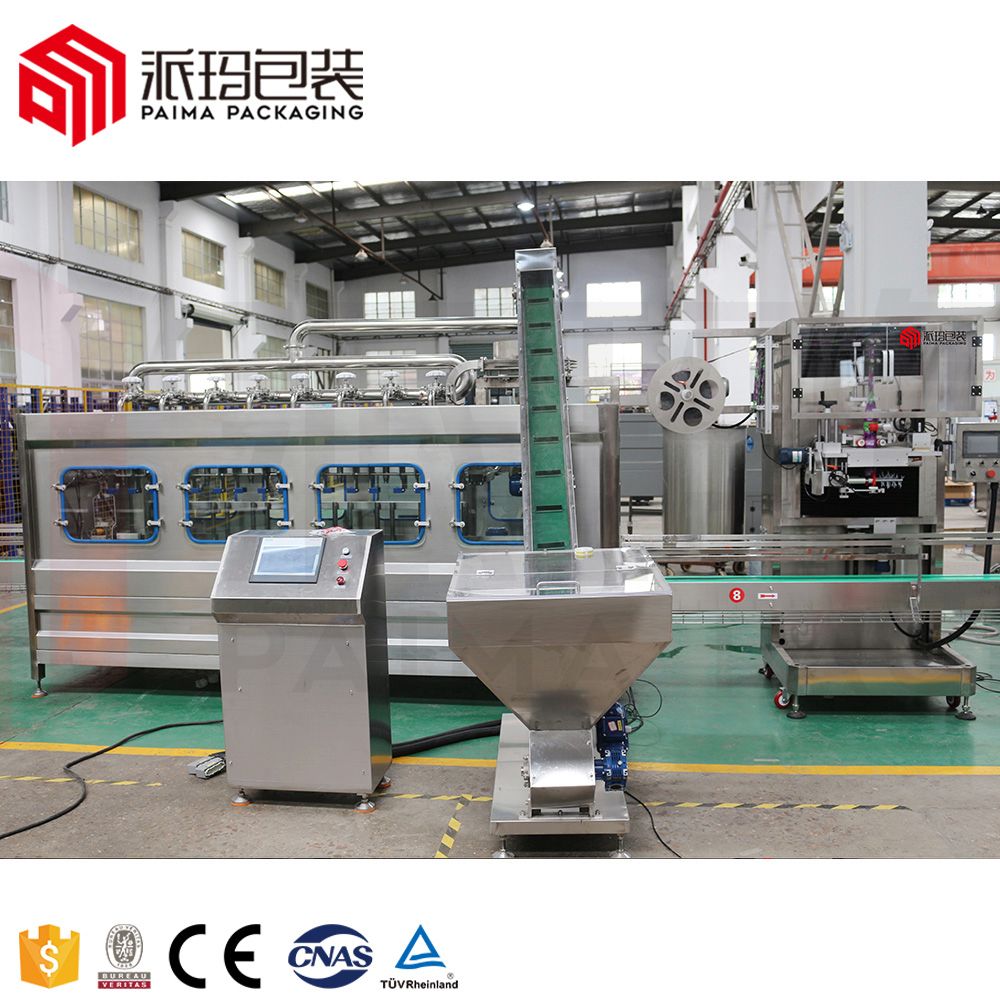

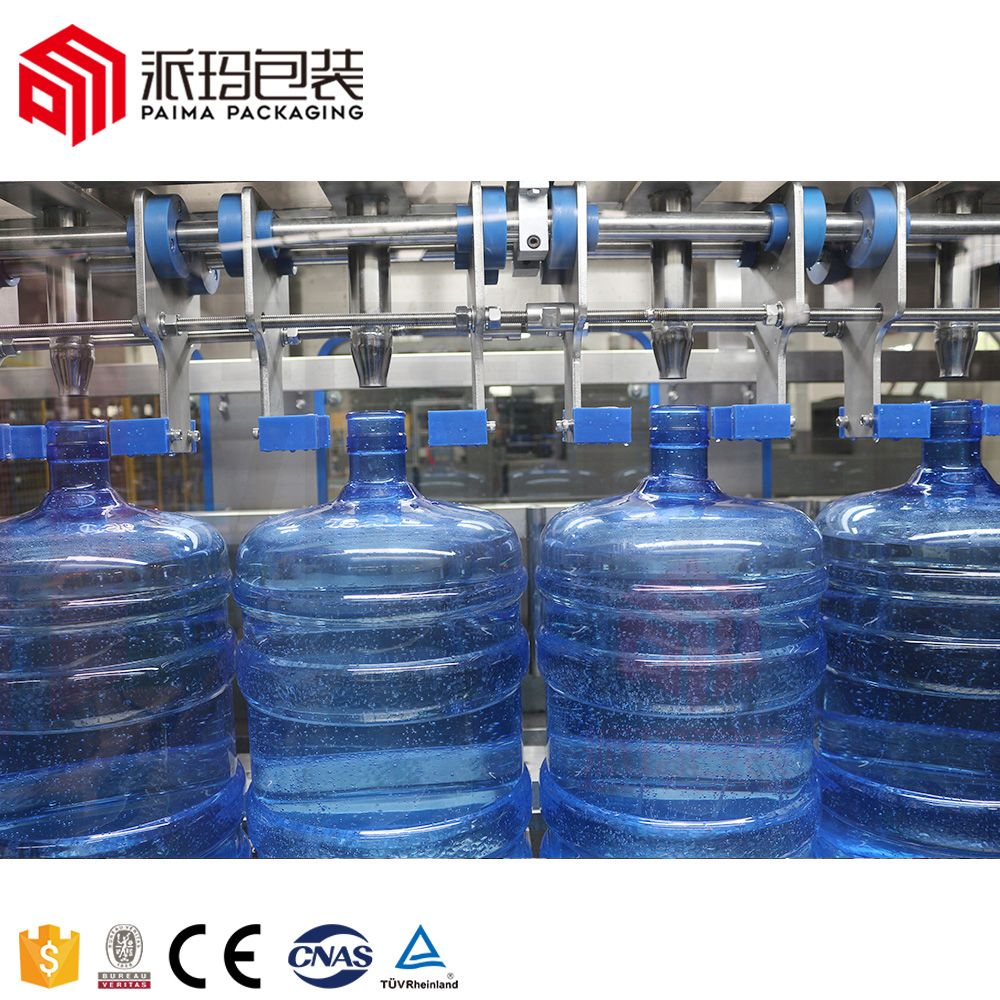

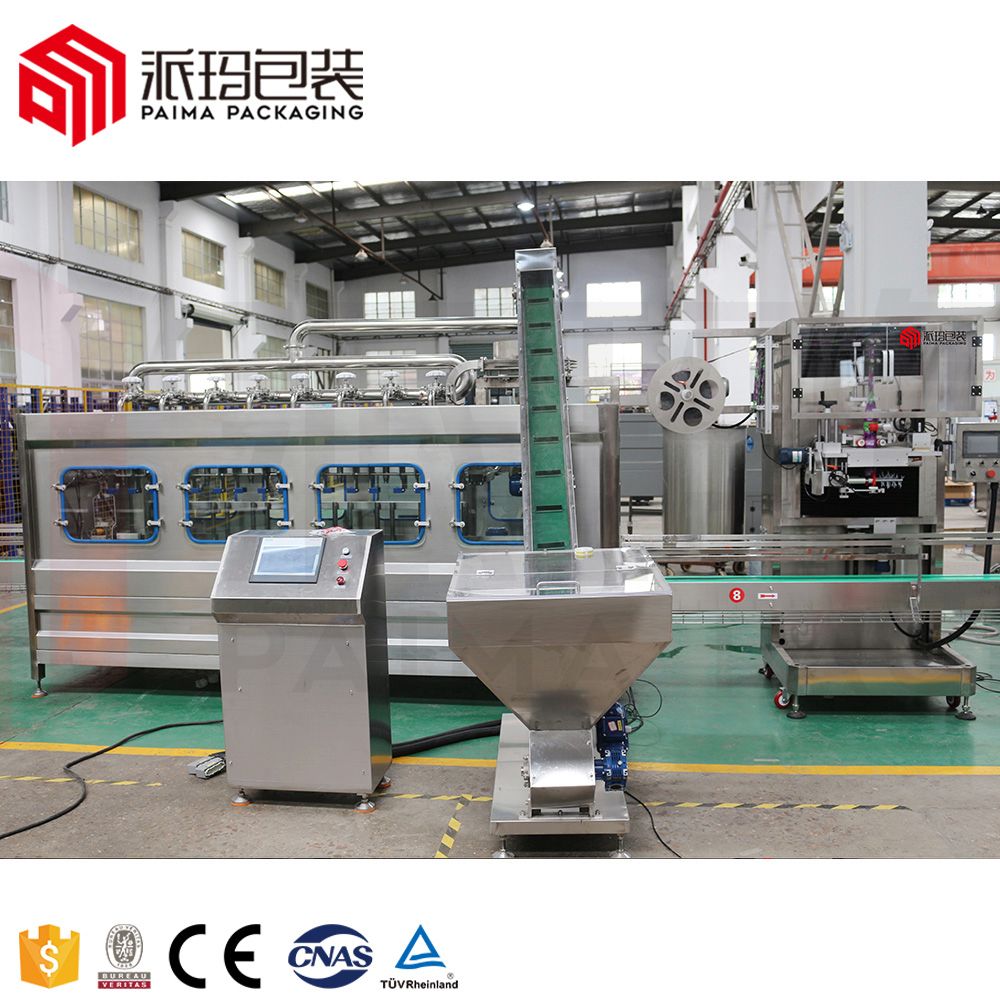

The 5-gallon water production line consists of empty bottle transfer, inner bottle brushing, automatic cap removal, outer bottle brushing, rinsing, filling and capping, light inspection machine, necking machine, bagging, full bottle transfer, and palletizing machine to achieve fully automatic and intelligent production.

Brief introduction of 3-5 gallon water filling machine

The 5-gallon water production line consists of empty bottle transfer, inner bottle brushing, automatic cap removal, outer bottle brushing, rinsing, filling and capping, light inspection machine, necking machine, bagging, full bottle transfer, and palletizing machine to achieve fully automatic and intelligent production. The whole process is strictly controlled to ensure full compliance with the customer's local standards and the regulations set by their health department. Secondary contamination is strictly controlled during the filling process, which makes it an ultra-clean line. This is one of the most ideal, recognized, and reliable automatic gallon water production lines for companies and plants. The line is mainly used to fill 3 and 5 gallons of pure or mineral water.

Main Features of 5-gallon water filling machine

1. The whole process is controlled by a computer or PLC with a high degree of automation.

2. Optional Internet-ready smart plant management software collects, transmits, stores, counts and analyzes real-time data, making remote control and digital production management easy.

3. Optimized technology reduces operating costs by reducing the consumption of water, electricity, and chemical materials.

4. The entire line is designed to fully comply with food safety quality regulations, avoiding dead spots, dead ends, static liquids, threaded joints, etc.

5. Extensive use of adapters, manholes, valves, etc. ensures the safety and easy maintenance.

6. The combination of proven technology and constant innovation ensures stability and reliability.

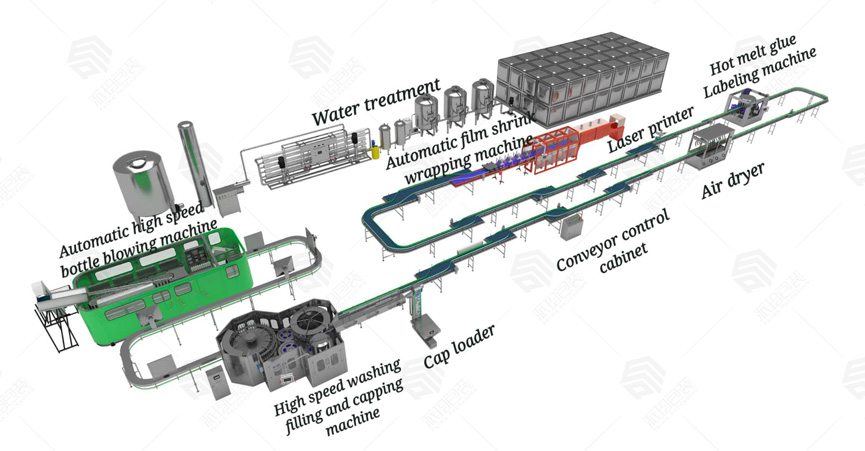

Full Production Line of Water Solutions

1. Bottle blowing system to make PET plastic bottles ( Semi-automatic / Fully automatic )

2. Water treatment system purifies water (Sand filter, carbon filter, RO/UF, Ozone sterilizer, UV sterilizer and etc.)

3. Air conveyor for empty bottle loading 4. 3 in 1 monoblock Rinser-filler-capper machine

5. Labeling machine(PVC sleeve labeling machine/OPP hot melt glue labeling machine/Self-adhesive labeling machine )

6. Cap loader load caps 7. Code printer (Ink-jet printer/ laser-jet printer)

8. End packaging ( PE shrink wrapping machine / Carton packing machine )

| 3-5 Gallon Water Filling Machine Bottle Material: PET Bottle Cap: Plastic Bottle Volume: 3-20L Production Speed: 100-1200bph Suitable Bottle: 3-5 gallon barrel bottles |

Automatic bottle decapper⇒Automatic bottle brush washer⇒Automatic bottle loader⇒Automatic bottle washer filler capper⇒Automatic cap washer⇒Automatic light checking and sealing machine

|  |

This de-capping machine is designed for 3 & 5-gallon bottles in the water production line. It's used to pull out the cap of the recycling bottle before rinsing. A combination of digital camera and fiber optic detectors allows to rejection of the bottles returned in the following conditions: Bottles without caps, Caps without plugs, Caps with just the top part left, Caps partially opened, Not removed caps.

|  |

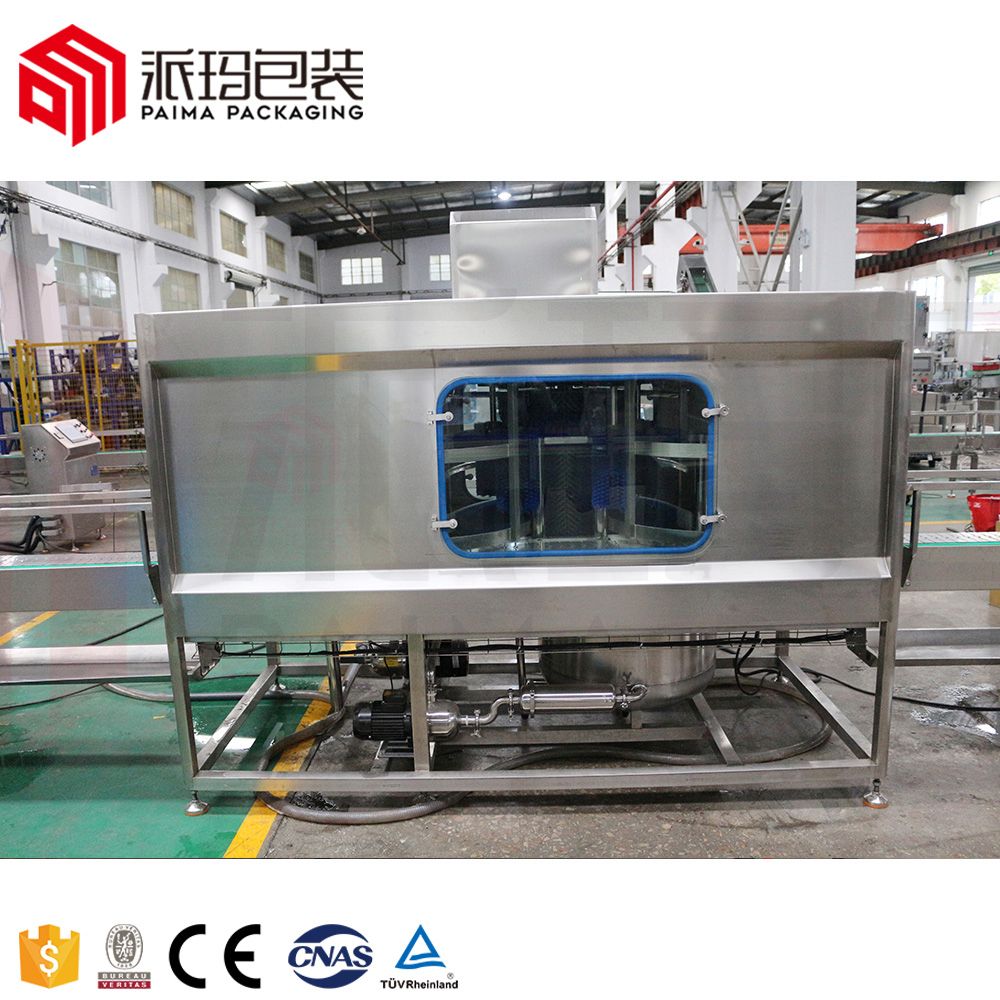

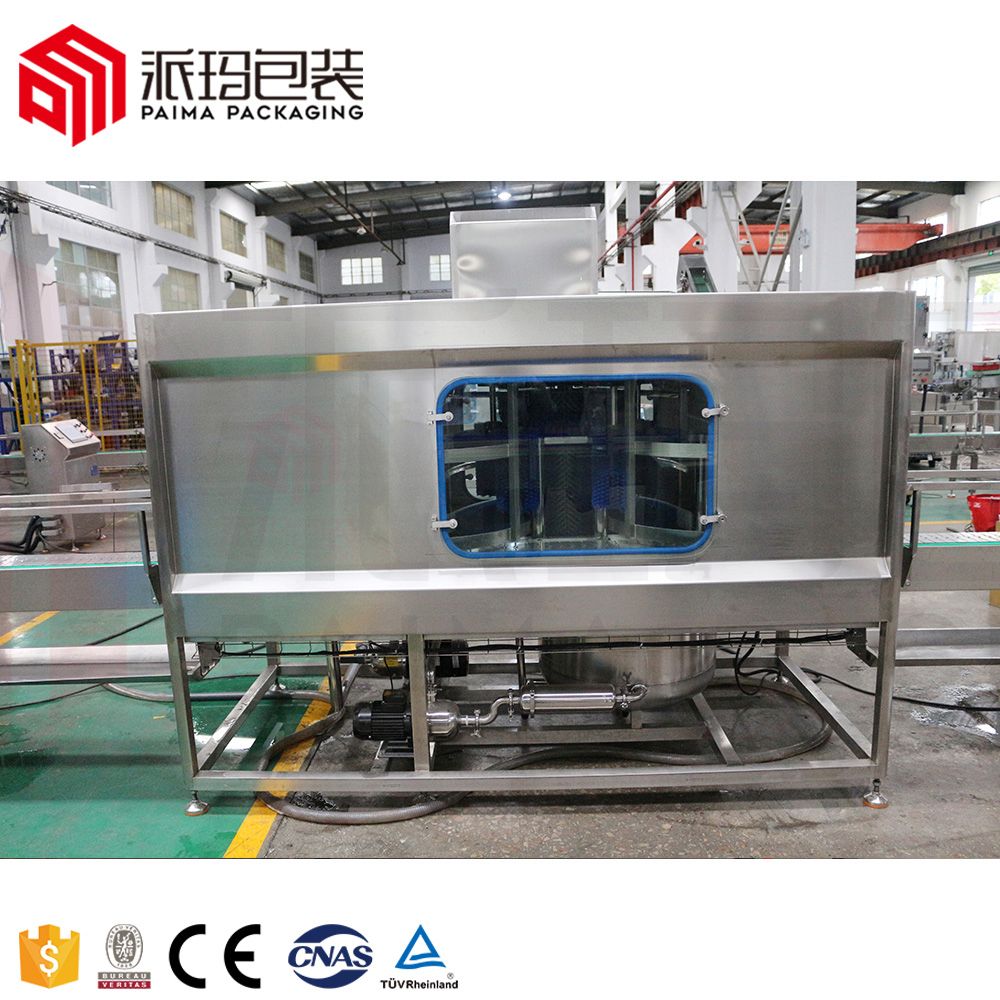

Brushes are motorized and clean the bottle externally. Since they make the bottle spin, the water jet hits not only the bottom but also the sides of the bottle. It's used for all-around cleaning the bottle, significantly improves cleaning efficiency.

|  |

1. It is designed for 5-gallon washing treatments.

2. It can manage 5 liters to 5 Gallons bottles.

3. Automatic bottle unloads and out load.

4. Neck handling of the bottle by the grippers.

5. Lack of point with water stagnation.

6. Automatic disinfection of the rinsing area.

7. Change-over easy and with no downtimes.

8. Easy access for ordinary maintenance.

|  |

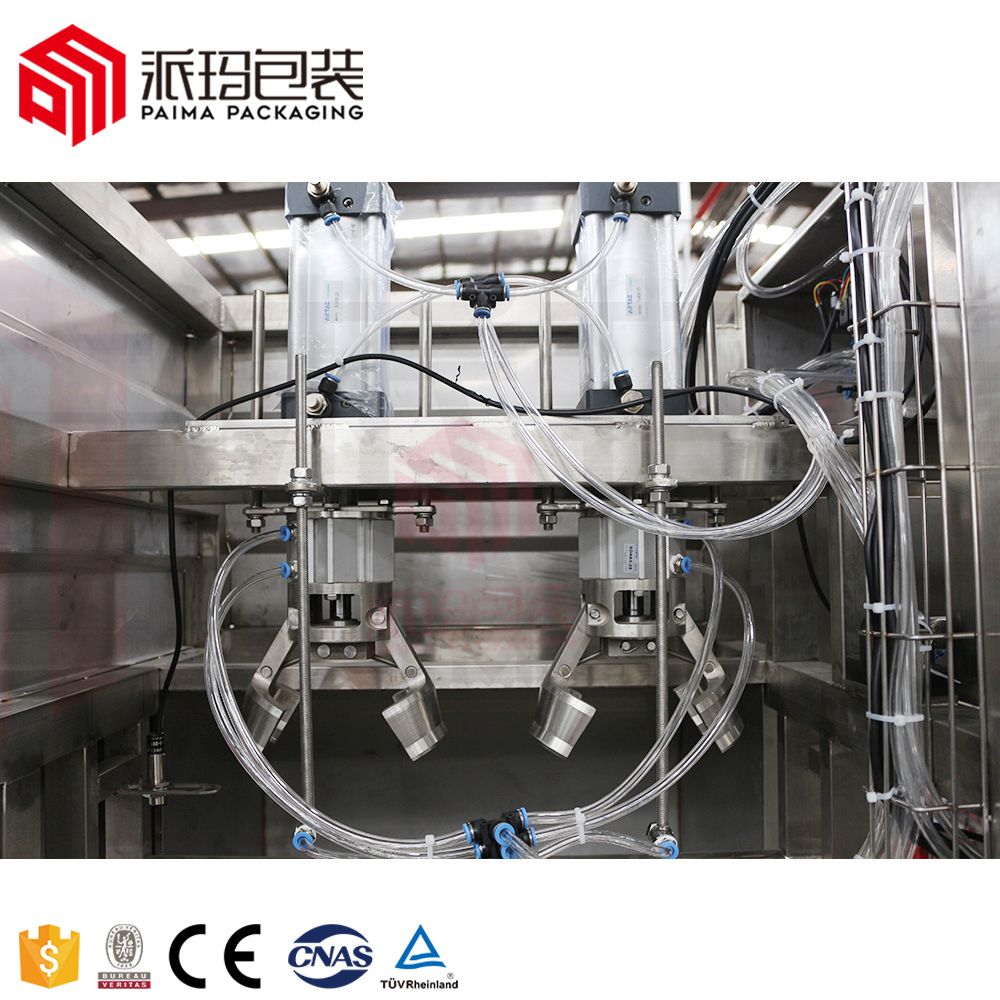

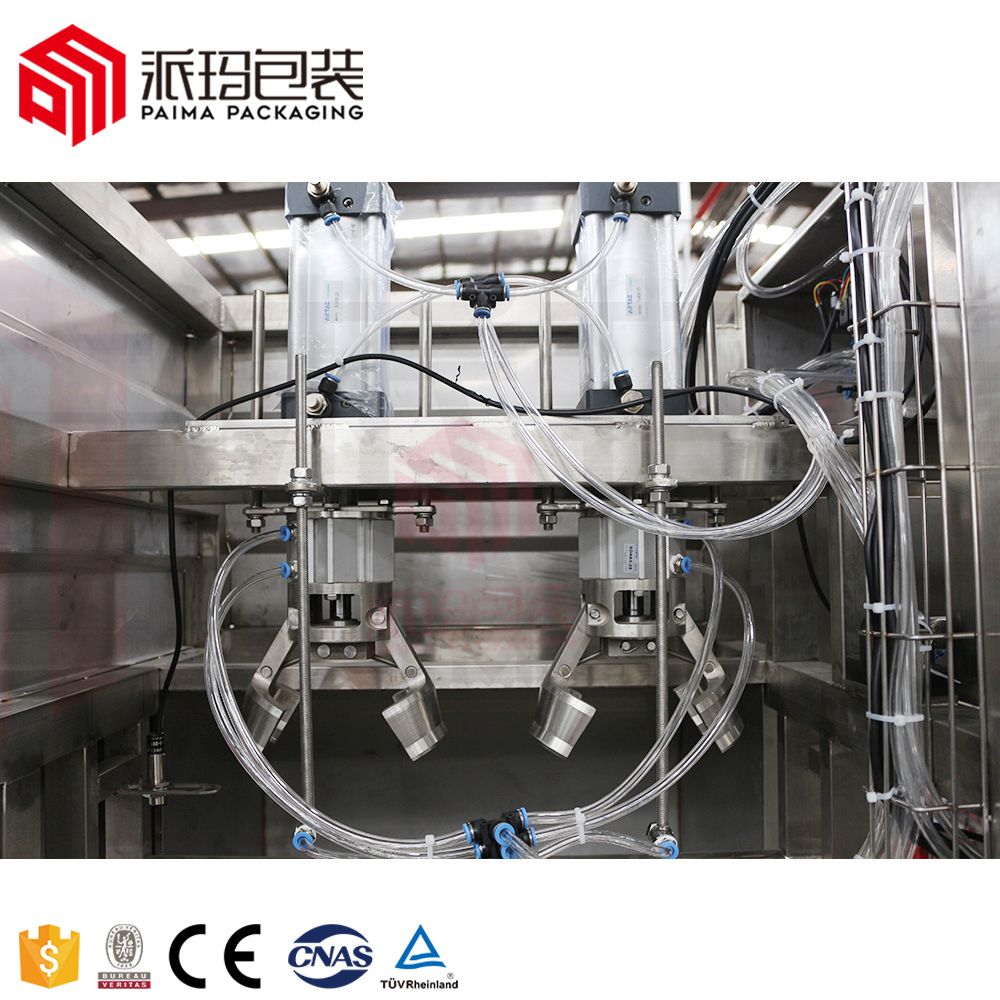

Uploading and dropping barrels changed from 45 degrees to translatory which is more stable.

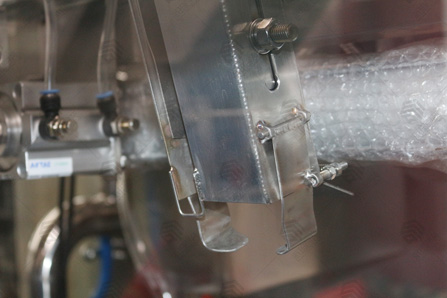

The nozzle can insert into 10-15cm of the barrel in order to rinse little impurities down. The rinsing pump is separately controlled by different magnetic valves. The pump only works when there is a barrel on that. It can avoid the mixture of different cleaning fluids.

|  |

The PRESS-ON CAPPER is a linear machine used for caps applied on the bottle by pressure.

It includes Cap hopper, a Canal chute, a Placing system of a cap on the neck, Device to snap the cap on the neck. Specific systems to sterilize the caps in order to avoid the contact of contaminating agents present on the cap with the bottleneck. The bottle takes the cap directly from the canal chute. The snapping of the cap on the bottleneck is carried out through the pressure developed by a belt conveyor, provided with a system to adjust the force in order not to stress the bottle.

Customer Cases

For nearly 12 years, Paima Packaging has provided bottling & packing equipment of liquid solutions to companies all over the world, water bottling lines, juice filling lines, carbonated soft drinks turnkey projects, oil and soda water bottling line, and labeling and packing machinery. Paima PacKaging offers complete filling and packaging solutions for the beverage industry and excellent lifelong time service.

We have a customer from Ethiopia who ordered a complete water line from water treatment to the back-end packaging equipment. And last year, when we went to Ethiopia to participate in the exhibition, we especially visited them. These are the real pictures we took from our customer's factory.

| ||

|  |  |

Our cooperation partner

Packing and Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient, and efficient packaging services will be provided.

| ||

|  |  |

ABOUT PAIMA:

Paima Packaging is a professional manufacturer that consists of research&design, production, and marketing in one unit, It is a professional manufacturer of beverage filling and packaging production line and packing material Since the establishment, we Rely on the ideal " faith and Steadfast, pursue remarkably" we insist on the realistic policy and show the perfect service to our customer, we always design and update our machine quality based on the ended user's actual use situation, due to our hard-working, we help our customer save a lot of labor cost and enhance their market competitiveness.

Due to the advanced technology, the fine processing equipment, we are already popular and reliable to our customers with its machine quality and faith, we welcome the customer from all around the world visit our company, thank you for your trust and help honestly, we believe mutual cooperate and respect mutual benefit and treat the person faithfully, in the end, we will succeed together.

FAQ:

1. HOW TO FIND US ?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufacturers and not traders

● Visit the exhibition in different countries

● Send us a request and tell us your basic inquiry

● Our sales manager will reply to you in a short time and add an instant chatting tool

2. YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fulfill your request and you interested in our products, you may pay a visit to Paima Machine site

● The meaning of visiting supplier, because seeing is believing, Paima Machine with own manufacture and developed& research team, we can send you engineers and make sure your after-sales service.

3. HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on-time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facticity of our bank account.

4. HOW TO ENSURE THE QUALITY ?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure stable running in the customers' factory

5. THE AFTER-SALE SERVICE OF PAIMA MACHINE ?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to the customers' factory to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customer's project.

want to know more about machines ? contact us now