want to know more about machines ? contact us now

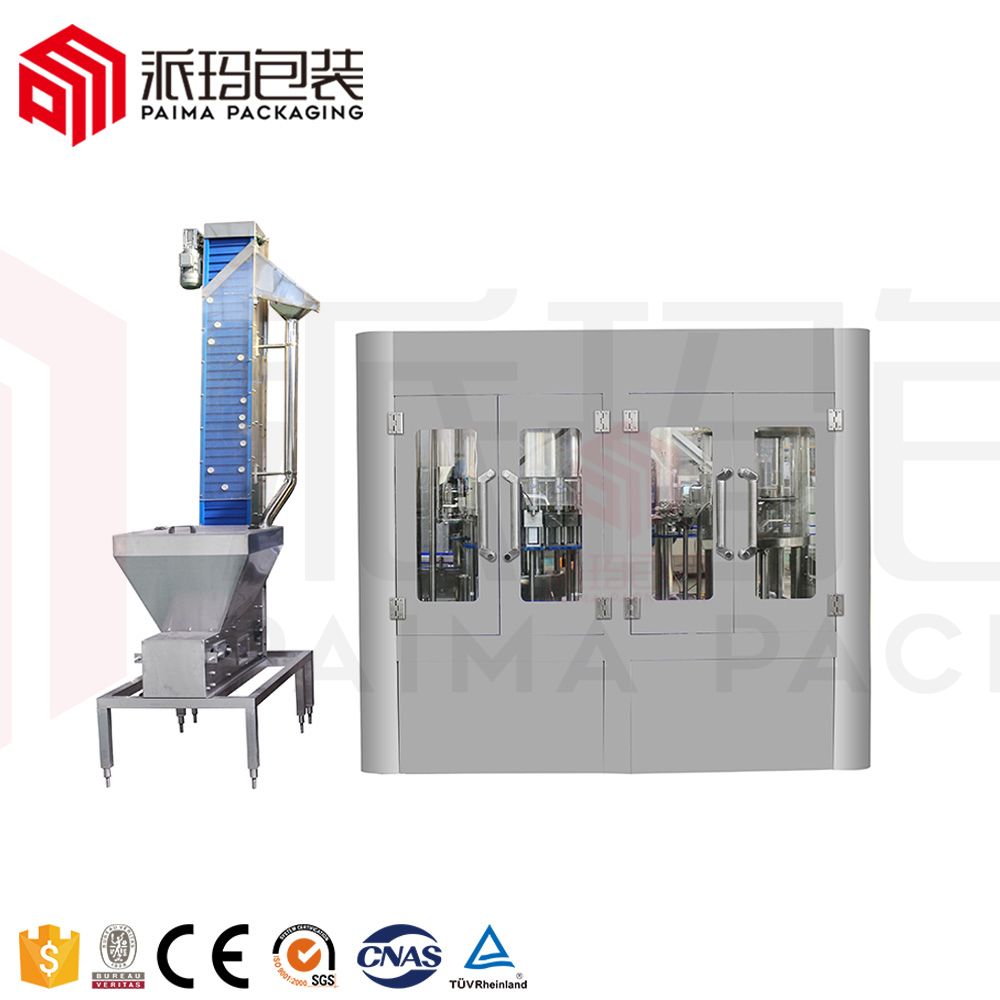

This automatic mineral water filling machine mainly used in the water filling operations, the three function of bottle washing, filling, and capping are composed in one body of the machine, the whole process is automatic, it is conveniently turned to adjust the machine to fill various types of bottles, the filling operation is faster and more stable due to the advanced filling valve technology, The famous brand programmed controller (PLC) is adopted to control the machine runs automatically. It is the ideal preferred equipment for the beverage maker

Brief introduction of water filling machine

3-in-1 filling monoblock, combined with rinsing, filling, and capping. It is innovated and designed in the requirement of still pure water and mineral water, on the basis of introducing, digesting, and absorbing the advanced technology from Germany and Italy.

The water filling machine is mainly used in beverage filling operations. The three functions of bottle wash, fill and seal is composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water, and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with a temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles. The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted.

Beverage Machinery can finish all the processes such as press bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

Main Features of water filling machine

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3. The specially designed stainless steel bottle washing machine clip is solid and durable, with no touch with the screw location of the bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurately, and no liquid loss.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

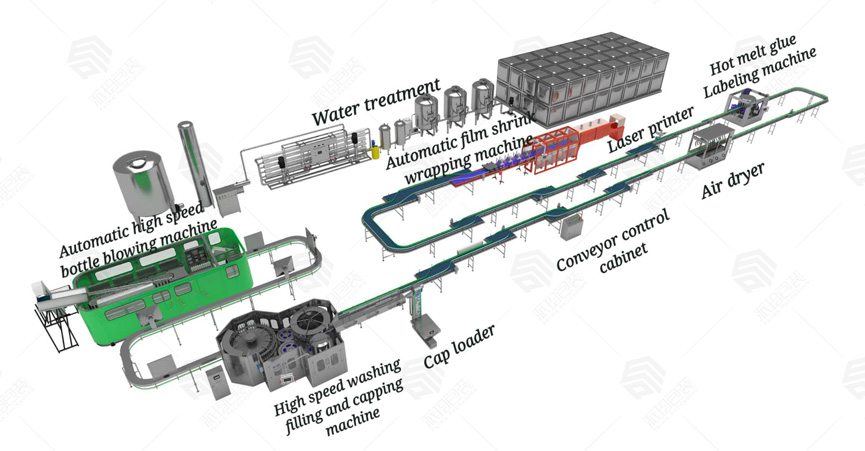

Full Production Line of Water Solutions

1. Bottle blowing system to make PET plastic bottles ( Semi-automatic / Fully automatic )

2. Water treatment system purifies water (Sand filter, carbon filter, RO/UF, Ozone sterilizer, UV sterilizer and etc.)

3. Air conveyor for empty bottle loading 4. 3 in 1 monoblock Rinser-filler-capper machine

5. Labeling machine(PVC sleeve labeling machine/OPP hot melt glue labeling machine/Self-adhesive labeling machine )

6. Cap loader load caps 7. Code printer (Ink-jet printer/ laser-jet printer)

8. End packaging ( PE shrink wrapping machine / Carton packing machine )

| Plastic Bottle Water Filling Machine Bottle Material: PET Bottle Cap: PE Bottle Volume: 100-2500ml Production Speed: 1000-32000bph Suitable Bottle: Height 170-320 Diameter 20-100 |

3000BPH 1500ML PLASTIC BOTTLE WATER FILLING LINE

Main Structures of Water Bottling Machine

1. Bottle infeed: Bottle infeed by the combination of infeed starwheels. Equipped with bottle jam protection device.

2. Discharge Starwheel: Nylon starwheel and conveyor belt work to discharge bottles.

3. Rinsing system: Combined with a rotary tray with clamp, water distributing tray, water tank, and rinsing pump.

4. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder.

5. Capping system: Combined with capper, cap sorter, and cap falling track.

6. Driving system: Combined with main motor and gears.

7. Bottle transmitting system: Combined with the air conveyor, steel starwheels, and neck supporting carrier plates.

8. Electrical controlling system: this part is frequency inverted, PLC controlled and touch screen operated.

Washing parts of water filling machine

1. Using a unique design, avoid the traditional bottle-on rubber clip to block the bottle-threaded parts that may be caused by the pollution.

2. Washing pump is made of stainless steel.

3. By high spray nozzle, a blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save the flush bottle.

4. Bottle clamp and flip agencies sliding sleeve adopts Germany igus corrosion-resistant bearing without maintenance.

Filling parts of water filling machine

1. Filling method for gravity filling.

2. Filling valve manufactured SUS 304/316L.

3. High precision, high-speed liquid filling.

4. Filling move by the rack drive system through gear transmission.

5. Hydraulic cylinder controlled by a float liquid level.

6. Using the latest double guide pillar type bottle of the lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance.

Capping parts of water filling machine

1. Automatic check, no bottle no capping.

2. Capping heads in stainless steel 304/316L.

3. Capping heads stop working when lack bottles.

4. Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without a cover machine, can effectively avoid the occurrence of an open bottle.

5. High-efficiency centrifugal principle.

Customer Cases

For nearly 12 years, Paima Packaging has provided bottling & packing equipments of liquid solutions to companies all over the world, water bottling line, juice filling line, carbonated soft drinks turnkey project, oil and soda water bottling line and labeling and packing machinery. Paima PacKaging offers complete filling and packaging solutions for the beverage industry and excellent lifelong time service.

We have a customer from Ethiopia who ordered a complete water line from water treatment to the back-end packaging equipment. And last year, when we went to Ethiopia to participate in the exhibition, we specially visited them. These are the real pictures we took from the our customer's factory.

| ||

|  |  |

Our cooperation partner

Packing and Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient, and efficient packaging services will be provided.

| ||

|  |  |

ABOUT PAIMA:

Paima Packaging is a professional manufacturer that consists of research&design, production, and marketing in one unit, It is a professional manufacturer of beverage filling and packaging production line and packing material Since the establishment, we Rely on the ideal " faith and Steadfast, pursue remarkably" we insist on the realistic policy and show the perfect service to our customer, we always design and update our machine quality based on the ended user's actual use situation, due to our hard-working, we help our customer save a lot of labor cost and enhance their market competitiveness.

Due to the advanced technology, the fine processing equipment, we are already popular and reliable to our customers with its machine quality and faith, we welcome the customer from all around the world visit our company, thank you for your trust and help honestly, we believe mutual cooperate and respect mutual benefit and treat the person faithfully, in the end, we will succeed together.

FAQ:

1. HOW TO FIND US ?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufacturers and not traders

● Visit the exhibition in different countries

● Send us a request and tell us your basic inquiry

● Our sales manager will reply to you in a short time and add an instant chatting tool

2. YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fulfill your request and you interested in our products, you may pay a visit to Paima Machine site

● The meaning of visiting supplier, because seeing is believing, Paima Machine with own manufacture and developed& research team, we can send you engineers and make sure your after-sales service.

3. HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on-time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facticity of our bank account.

4. HOW TO ENSURE THE QUALITY ?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure stable running in the customers' factory

5. THE AFTER-SALE SERVICE OF PAIMA MACHINE ?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to the customers' factory to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customer's project.

want to know more about machines ? contact us now