The introductions of water filling machine

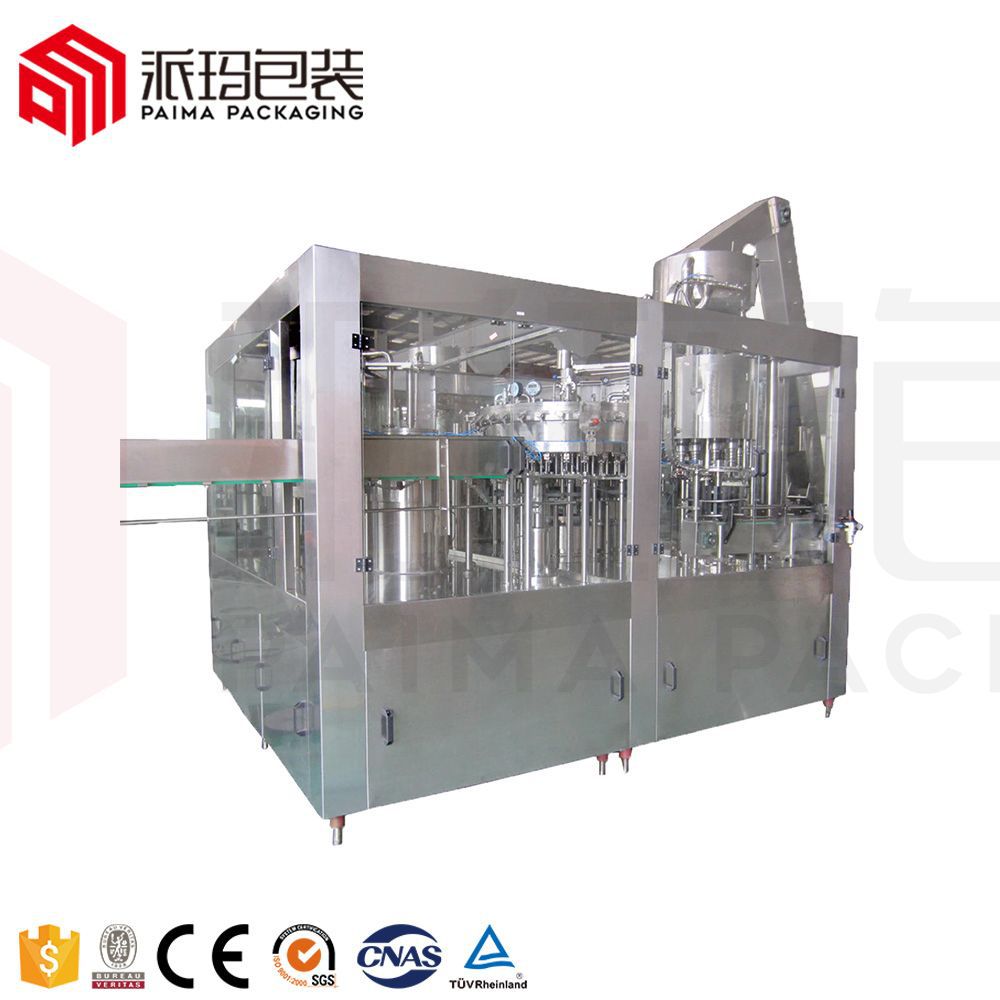

Our automatic mineral water filling machine is mainly used for water filling operations. This filling machine is an all-in-one machine, including three functions of bottle washing, filling, and capping. The entire filling process is safe and environmentally friendly. Advanced filling valve technology can easily adjust the machine to fill a variety of bottle types with fast filling operation speed and high stability. A famous brand of the programmable controller (PLC) is used to control the automatic operation of the machine. It is one of the ideal equipment for beverage manufacturers.

The functions of water filling machine

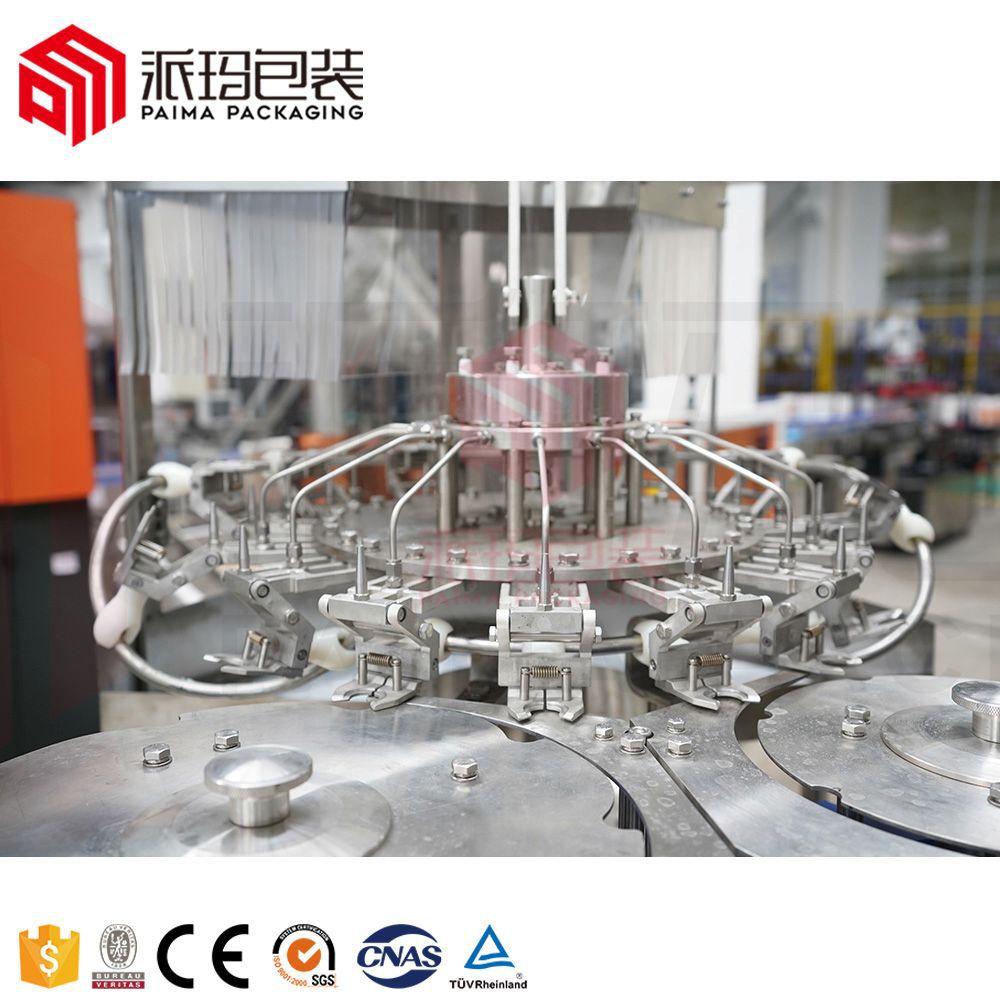

Washing heads

1.Using a unique design, avoid the traditional bottle on rubber clip to block the bottle threaded parts may be caused by the

pollution.

2.Washing pump is made of stainless steel.

3. By high spray nozzle, a blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save the flush bottle.

4. Bottle clamp and flip agencies sliding sleeve adopts Germany igus corrosion-resistant bearing without maintenance.

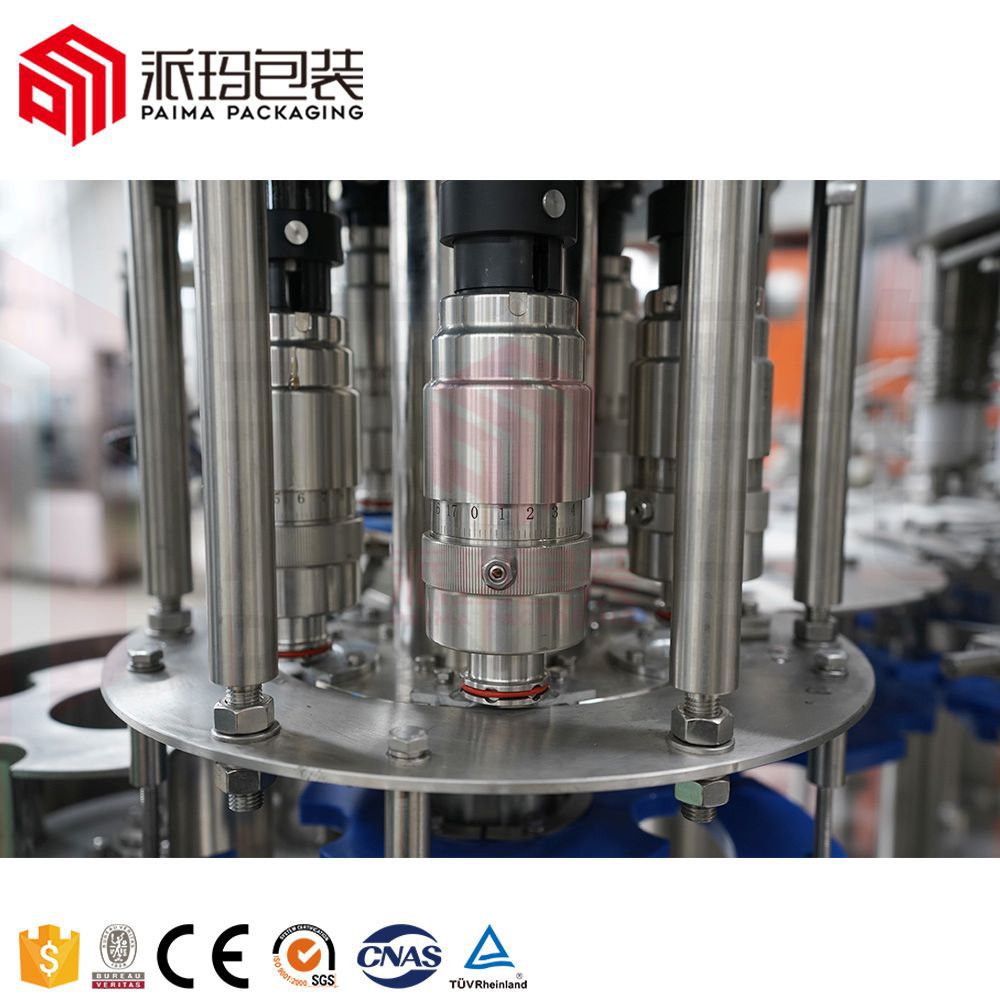

Filling heads

1.Filling method for gravity filling.2.Filling valve manufactured SUS 304/316L.

3.High precision, high-speed liquid filling.

4.Filling move by the rack drive system through gear transmission.

5.Hydraulic cylinder controlled by a float liquid level.

6.Using the latest double guide pillar type bottle of the lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance.

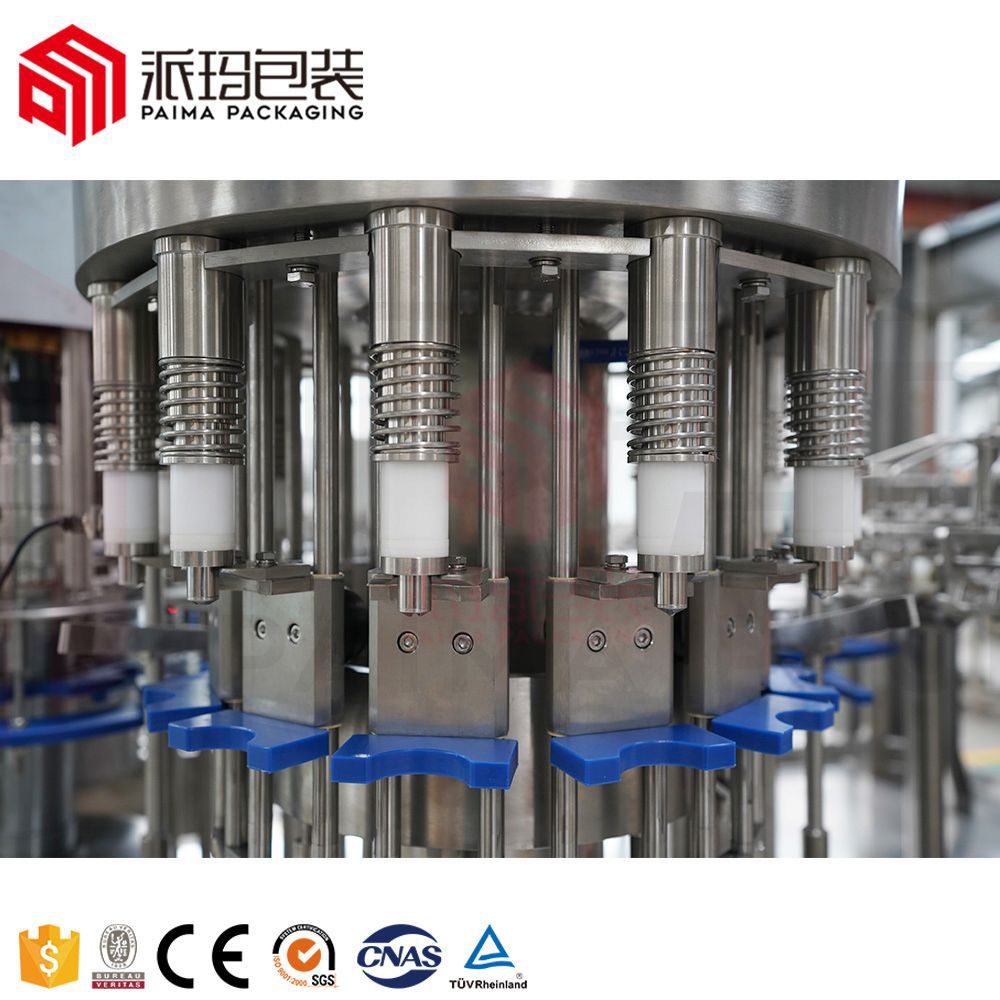

Capping heads

1.Automatic check, no bottle no capping.2.Capping heads in stainless steel 304/316L.

3.Capping heads stop working when lack of bottle.

4.Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without a cover machine, can effectively avoid the occurrence of an open bottle.

5.High efficiency centrifugal principle.

The details of the water filling machine

The Features of water filling machine

1. Smart touch screen, humanized design, easy to operate.

2. High-speed filling valve to avoid dripping and leakage and the filling volume are accurate.

3. Program Logic Controller (Plc), easy to change the size, or modify parameters.

4. Pneumatic components are all well-known brands, stable and reliable.

5. Photoelectric sensor and pneumatic link control can automatically protect bottle shortage.

6. Pneumatic execution control valve, high efficiency, and safety.

7. Tight positioning design, easy to manipulate, suitable for packaging bottles of various sizes.

8. The machine is designed according to the buyer's requirements

The parameter of water filling machine

Model | CGF8-8-3, 12-12-6, 18-18-6, 24-24-8, 32-32-8,40-40-10, 50-50-12, 60-60-15 |

Application | Springwater / mineral water / pure water / non-gas wine drink and so on |

Production capacity(500ml) | 1000-25000BPH |

Filling precision | ≤±5mm(liquid level) |

User Ambient Conditions | Temperature:10~40℃; Humidity: No dew |

Suitable bottle specification | Volume=100-2500ml Diameter φ=50-110 Bottle height H=150 ~350mm |

Machine material | Food stage SS304 OR SS316 |

Air source pressure (Mpa) | 0.5-0.6 |

Motor power(kW) | Main motor 5.12kw |

Control System | SIMENS PLC+ TOUCH SCREEN |

Power Supply | Voltage:220V~4150V,3phase; Frequency:50HZ/60HZ or your requirement |

Overall dimensions (mm) | 2900*2100*2400 |

Weight (kg) | 4500 |

Certificates | CE / SGS / ISO 9001/ CCC |