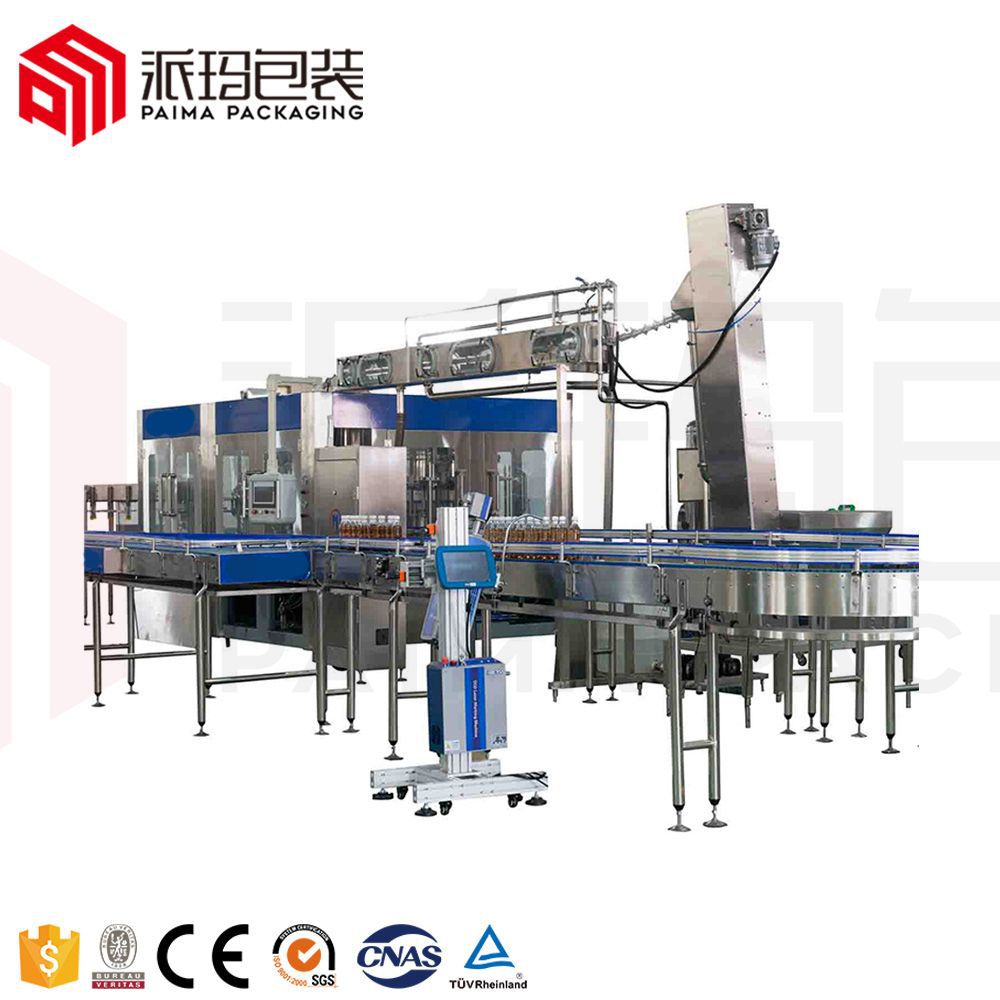

● Visit exhibition in different countries

● Send us an request and tell your basic inquiry

● Our sales manager will reply you in short time and add instant chatting tool

2.YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to Paima Machine site

● The meaning of visiting supplier, because seeing is believing, Paima Machine with own manufacture and developed& research team,

we can send you engineers and make sure your after sales service.

3.HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facticity of our bank account.

4.HOW TO ENSURE THE QUALITY?

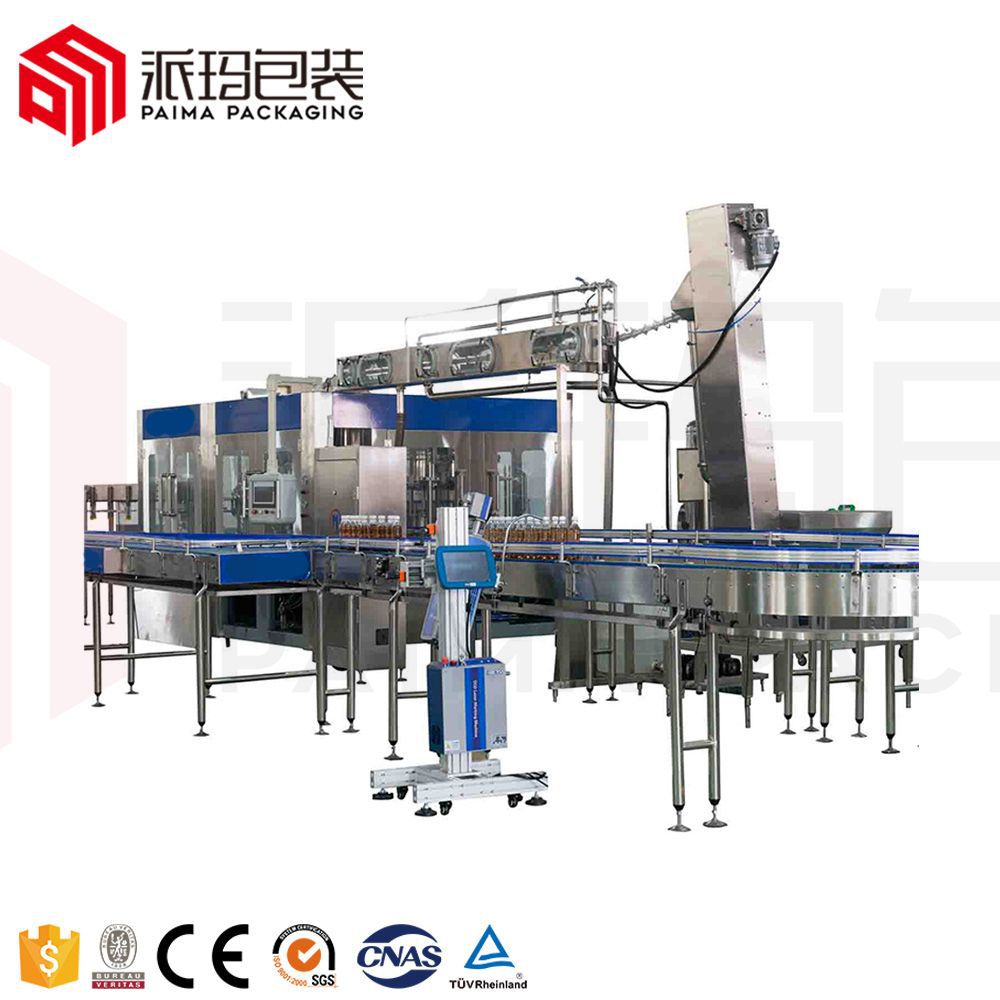

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

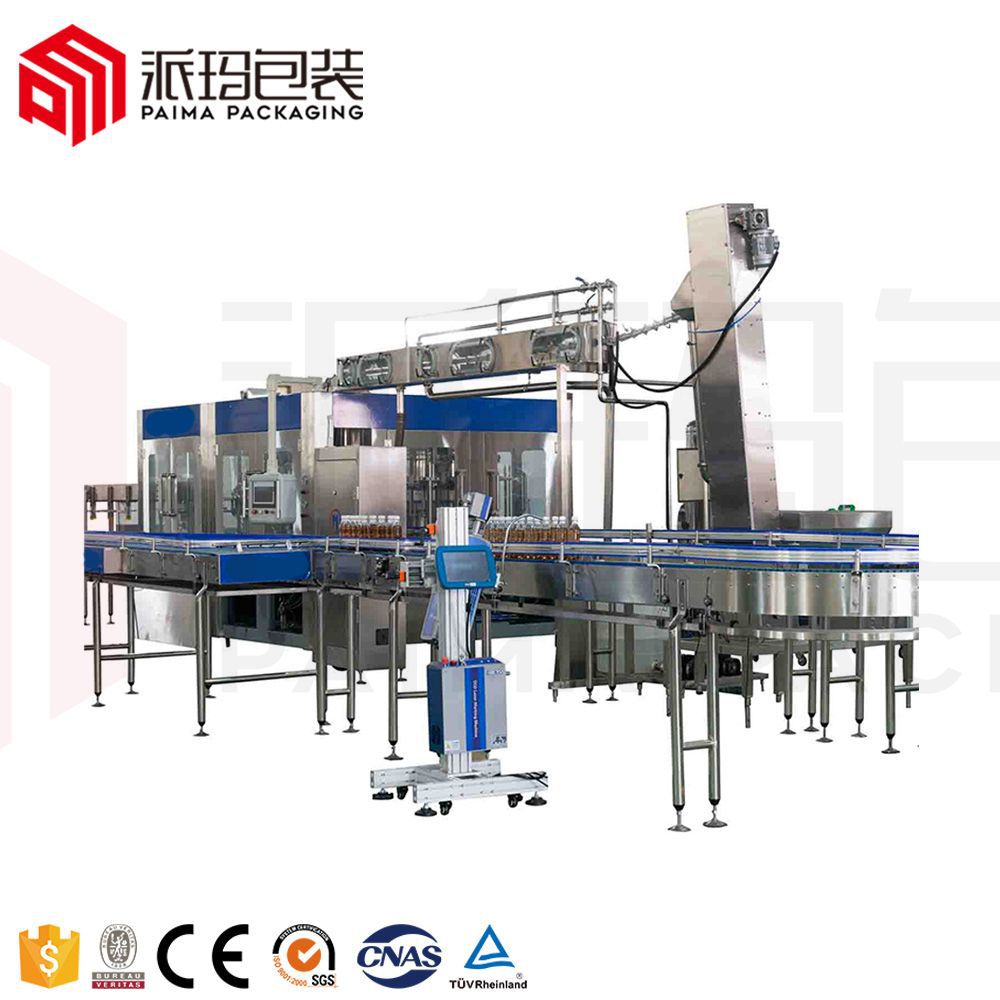

5.THE AFTER-SALE SERVICE OF PAIMA MACHINE?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.